PTC composite material heating film and manufacturing method and application thereof

A composite material and composite material layer technology, applied in the field of PTC composite material heating film, can solve the problems of slow heating speed, no heating film using composite materials, easy to cause fire and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

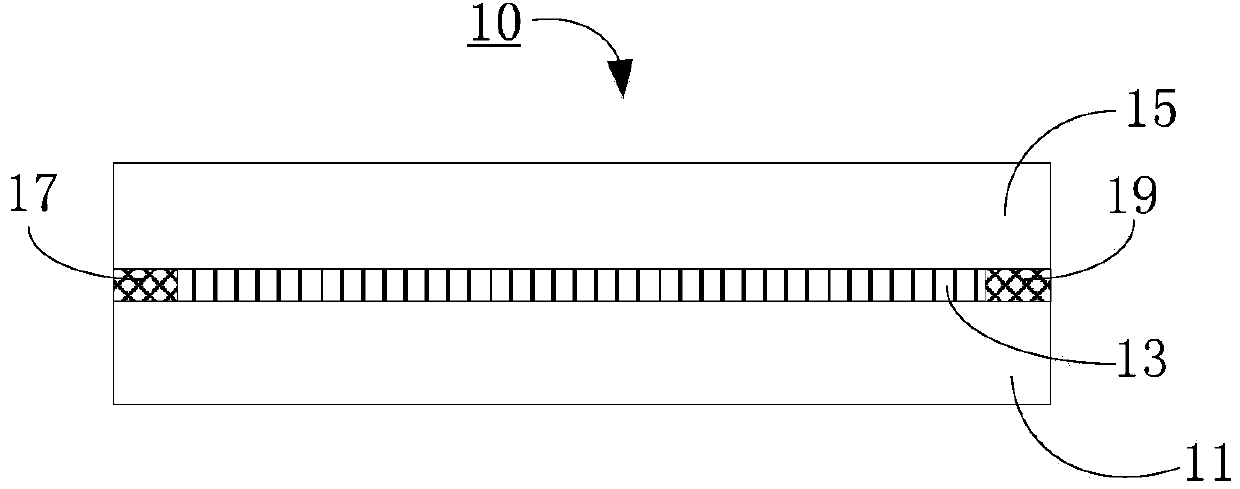

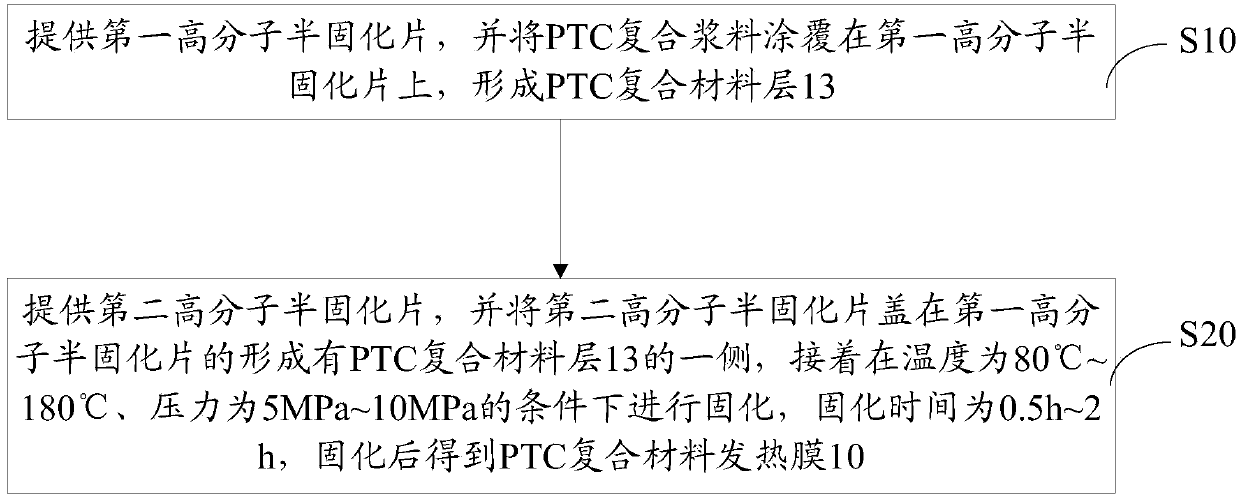

[0035] Such as figure 2 The preparation method of the above-mentioned PTC composite heating film 10 shown includes the following steps:

[0036] S10 , providing a first polymer prepreg, and coating the PTC composite slurry on the first polymer prepreg to form a PTC composite material layer 13 .

[0037] The first polymer prepregs can be purchased directly from the market as finished products. Prepregs made of epoxy resin are generally selected.

[0038] The solute of the PTC composite slurry is a mixture composed of 20-90 parts by mass of conductive particles, 10-80 parts of high molecular polymer and 1-10 parts of additives.

[0039] Conductive particles are selected from at least one of carbon black, graphite powder, carbon fiber powder, metal powder, carbon nanotubes and graphene

[0040] The high molecular polymer is at least one selected from polyamide, polyethylene, polypropylene, polyvinylidene fluoride, polychlorotrifluoroethylene, epoxy resin and polyimide.

[00...

Embodiment 1

[0057] Weigh 6g of carbon fiber powder and 4g of epoxy resin. Soak the carbon fiber powder in methyl ethyl ketone and stir for one hour, wash off the gum on the surface of the carbon fiber, pour off the methyl ethyl ketone, then put the carbon fiber powder and epoxy resin into a clean container, and dry it at 80°C. The epoxy resin was dissolved in methyl ethyl ketone. The curing agent dicyandiamide is used as an additive, and 0.24 g of dicyandiamide is weighed and dissolved with N,N-dimethylformamide. The curing agent solution, the epoxy resin solution and the carbon fiber powder were mixed and stirred continuously for 1 hour to obtain a uniformly mixed PTC composite slurry.

[0058] Provide the first polymer prepreg made of epoxy resin, print the PTC composite slurry on the first polymer prepreg with a screen printing machine to form a PTC composite slurry layer, and then paste on both ends of the PTC composite slurry layer Copper foil is used as an electrode, kept at 120°C...

Embodiment 2

[0060] Weigh 3g of carbon black and 7g of epoxy resin. Soak the carbon black in methyl ethyl ketone and stir for one hour, wash off the colloid on the surface of the carbon black, pour off the methyl ethyl ketone, then put the carbon black and epoxy resin into a clean container, and dry it at 80°C. The epoxy resin was dissolved in methyl ethyl ketone. The curing agent dicyandiamide is used as an additive, and 0.36 g of dicyandiamide is weighed and dissolved with N,N-dimethylformamide. The curing agent solution, the epoxy resin solution and the carbon fiber powder were mixed and stirred continuously for 1 hour to obtain a uniformly mixed PTC composite slurry.

[0061] Provide the first polymer prepreg made of epoxy resin, print the PTC composite slurry on the first polymer prepreg with a screen printing machine to form a PTC composite slurry layer, and then paste on both ends of the PTC composite slurry layer Copper foil is used as an electrode, kept at 120°C for one hour, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com