Bacterial cellulose fiber containing nano-silver chloride particles and preparation method of fiber

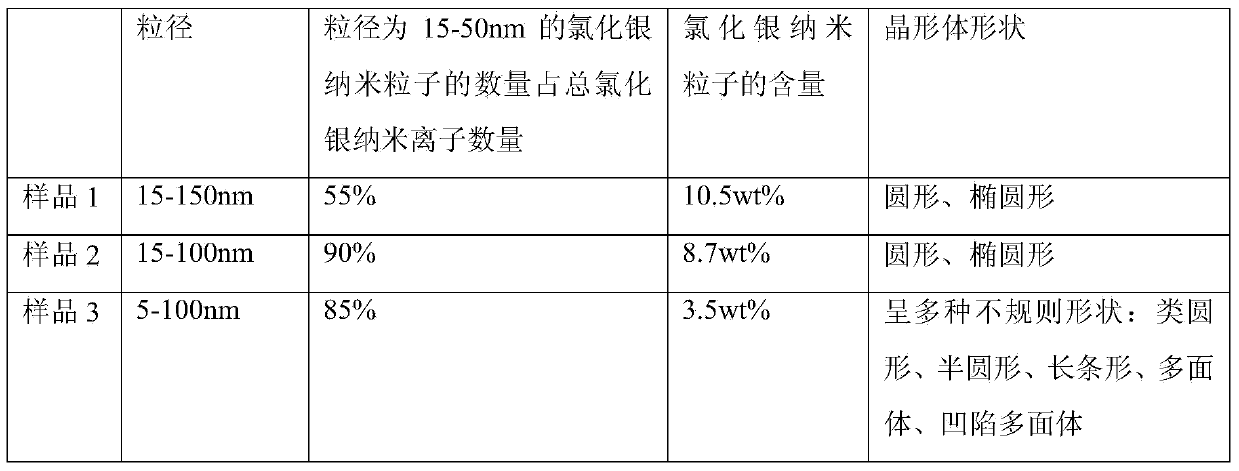

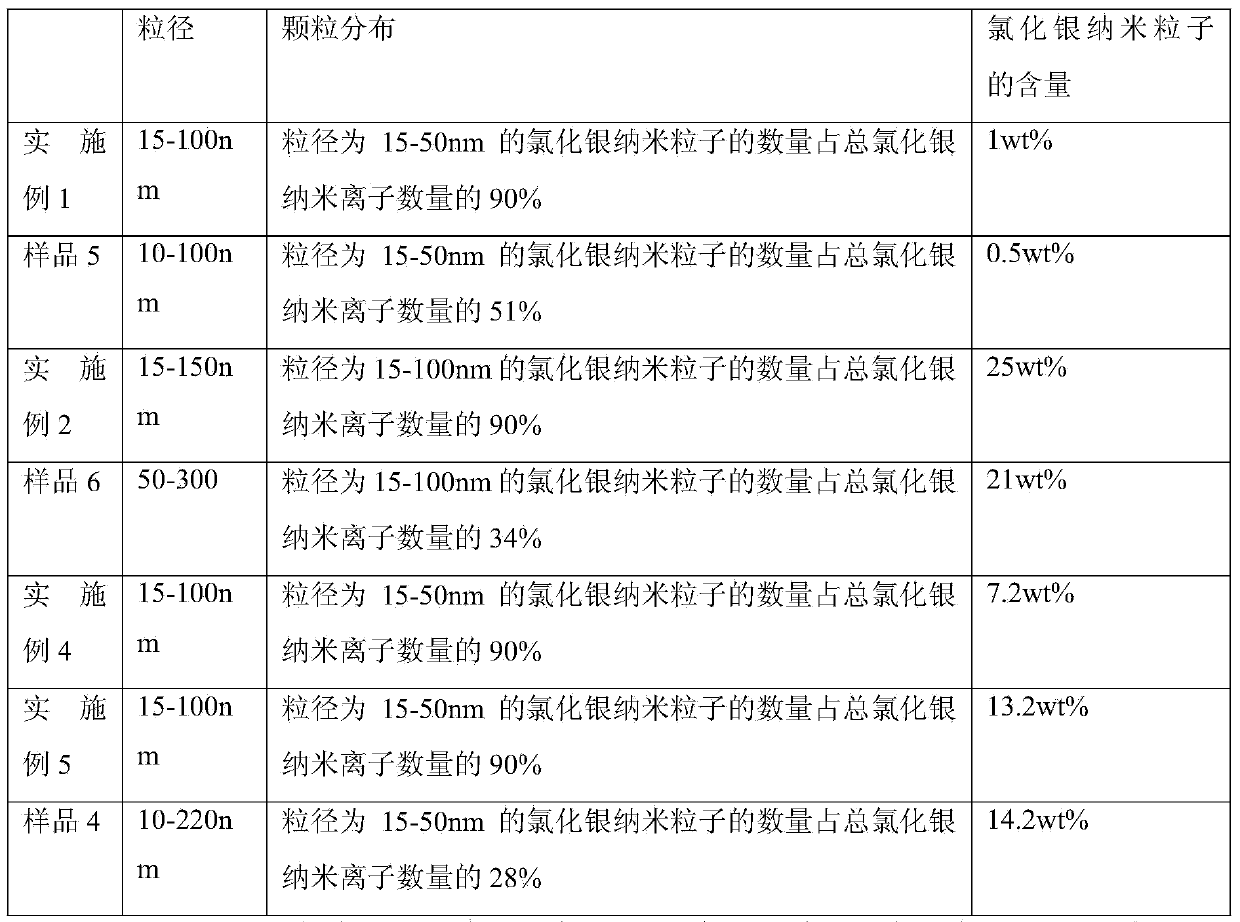

A bacterial cellulose and nanoparticle technology, which is applied in the direction of single-component cellulose artificial filament, plant fiber, fiber treatment, etc., can solve the problems of wide particle size distribution, uneven size, and large particle size of silver chloride particles , to achieve the effect of improving photocatalytic ability, easy degradation and strong water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1. Preparation of bacterial cellulose fiber: (1) After pulverizing and drying bacterial cellulose with a degree of polymerization of 1000, add 1.5mol / L sodium hydroxide / 0.65mol / L thiourea system, and dissolve it at -5°C The spinning solution with a mass percentage concentration of 2.5% is stirred evenly and left to stand for 12 hours, filtered, and defoamed; (2) the spinning solution enters the spinneret hole through a metering pump and is ejected into a coagulation bath, which is water at a temperature of 70°C, and then subjected to two-stage stretching with saturated water vapor, the stretching temperature is 100°C, the total stretching ratio is 1.5 times, and then washed with water.

[0041] Step 2. The bacterial cellulose as-spun fiber prepared in step 1 is introduced into a silver nitrate solution bath with a temperature of 50° C., a pH of 7, and a concentration of 0.0005 mol / L through guide rollers at room temperature, and the tow runs in the solution for 1 mi...

Embodiment 2

[0045] Step 1. Preparation of bacterial cellulose fiber: (1) After pulverizing and drying the bacterial cellulose with a degree of polymerization of 2500, add ethylenediamine solution for activation treatment, take it out after washing and drying, and add lithium chloride / dimethylacetamide (chloride The mass percent content of lithium is 10%) solution, dissolved at 35°C to make a spinning solution with a mass percent concentration of 3.5, stirred evenly and then left to stand for 12 hours, filtered and defoamed; (2) The spinning solution enters through a metering pump The spinneret hole is sprayed out and enters the coagulation bath. The coagulation bath is an aqueous solution of dimethylacetamide with a concentration of 20% by mass at a temperature of 15°C, and then stretched by saturated water vapor in a first stage. The stretching temperature is 100°C and the stretching ratio is 1.0 times, followed by washing.

[0046] Step 2. The bacterial cellulose as-spun fiber prepared ...

Embodiment 3

[0050] Step 1. Preparation of bacterial cellulose fibers: (1) After pulverizing and drying the bacterial cellulose with a degree of polymerization of 5000, adding an aqueous solution of NMMO with a concentration of 50% by mass for premixing to obtain an incompletely dissolved pulpy cellulose mixture for suspension solution, and then distill off excess water under reduced pressure to reduce the water content of the solvent to 13%-15%, and make a spinning solution with a concentration of 5% by mass percentage, stir it evenly, let it stand for 12 hours, and filter , defoaming; (2) the spinning slurry enters the spinneret hole and sprays out into the air gap through the metering pump, the medium of the air gap is air, the temperature is room temperature, and the length is 3cm; then enters the coagulation bath, the coagulation bath is water, the bath temperature 70°C, and then stretched in three stages with saturated water vapor, the stretching temperature is 150°C, the total stretc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com