Separating and purifying method for obtaining highly pure teicoplanin

A technology for separation and purification of teicoplanin, which is applied in the field of separation and purification of high-purity teicoplanin, can solve the problems of expensive chromatographic packing material, high production cost, unfavorable industrial application, etc., and achieve the effect of high separation purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

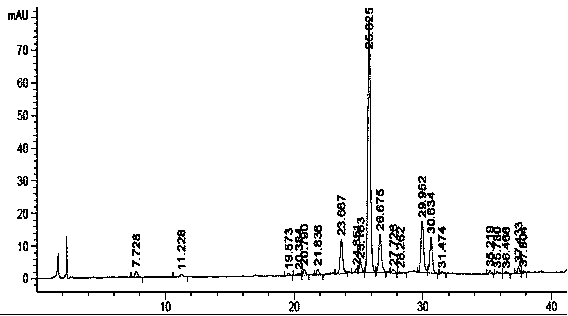

Image

Examples

Embodiment 1

[0023] Pass 70L of teicoplanin fermentation broth through a microfiltration membrane (pore size 0.1 μm, ceramic microfiltration membrane) to remove solids in the fermentation broth. After the fermentation broth is fed, add 2 times the volume of water to wash the solids to recover Teicoplanin product. Combined to obtain 180L of filtrate, the filtrate was concentrated to 70L by nanofiltration (molecular weight cut-off 700-800Da), the concentration of the concentrated solution was 6.02g / L, and the content of teicoplanin was 421.4g.

[0024] Take 17L nanofiltration concentrate (teicoplanin content 102.34g), and install 9L AMBERLITE XAD 7HP resin on it for adsorption, and the sample loading flow rate is 9L / h. After loading the column, wash the resin with 27L deionized water to remove unadsorbed impurities, and the cleaning flow rate is 18L / h; continue to use 50L 15% acetone aqueous solution (containing 20g / LNaH 2 PO 4 , phosphoric acid to adjust the pH to 4.5) to clean th...

example 2

[0030] Take 30L nanofiltration concentrated liquid (teicoplanin content: 180.6g) in Example 1, and install 10L HZ801 resin on it for adsorption, and the sample loading flow rate is 10L / h. After loading the column, wash the resin with 30L deionized water to remove unadsorbed impurities, and the cleaning flow rate is 20L / h; continue to use 50L 16% acetonitrile aqueous solution (containing 20g / LNaH 2 PO 4 , phosphoric acid to adjust the pH to 4.5) to clean the resin to remove impurities with weak adsorption capacity, the flow rate is 10L / h; finally use 30% acetonitrile aqueous solution (containing 20g / L NaH 2 PO 4 , phosphoric acid to adjust pH4.5) elution, flow rate 10L / h. A total of 14.6 L of eluent was collected, the potency was 11.4 g / L, and 166.44 g of teicoplanin was recovered, the process yield was 92.1%, and the purity of the product by liquid chromatography was 81.5%.

[0031] The teicoplanin eluate was diluted with deionized water until the concentration of ac...

Embodiment 3

[0036] Take 20L nanofiltration concentrated liquid (teicoplanin content: 120.4g) in Example 1, and install 6L AMBERLITE XAD 1180N resin on it for adsorption, and the sample loading flow rate is 6L / h. After loading the column, wash the resin with 24L deionized water to remove unadsorbed impurities, and the cleaning flow rate is 12L / h; continue to use 24L 22% isopropanol aqueous solution (containing 20g / L 2 PO 4 , phosphoric acid to adjust the pH to 4.5) to clean the resin to remove impurities with weak adsorption capacity, the flow rate is 10L / h; finally use 34% isopropanol aqueous solution (containing 20g / L NaH 2 PO 4 , phosphoric acid to adjust pH4.5) elution, flow rate 6L / h. A total of 13.8 L of eluent was collected, the potency was 7.59 g / L, and 104.86 g of teicoplanin was recovered, the process yield was 87.1%, and the purity of the product by liquid chromatography was 85.5%.

[0037] The teicoplanin eluate was diluted with deionized water until the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com