A kind of composite oxide supported ruthenium ammonia synthesis catalyst and preparation method thereof

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low specific surface area of catalyst carrier and restriction of catalyst ammonia synthesis activity and other problems, to achieve good industrial application prospects, low-temperature and low-pressure ammonia synthesis activity improvement, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

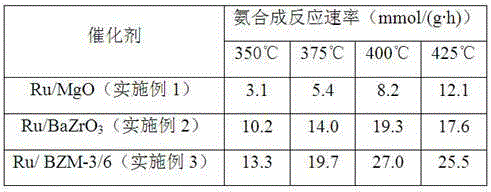

[0034] Embodiment 1 (comparative example)

[0035] Mg(NO 3 ) 2 ·6H 2 O: A mixture of citric acid: ethylene glycol with a molar ratio of 1:2:4 was dissolved in an appropriate amount of distilled water to obtain a colorless clear viscous liquid. The solution was slowly heated in a water bath at 80°C for 4h to evaporate excess water, and then heated at a constant temperature of 90°C for 12h to promote the gelation of the mixture. Finally, the obtained gel was calcined at 300°C for 1 h to obtain the precursor, and then calcined at 750°C for 3 h to obtain the MgO support material. The active component ruthenium was impregnated into the carrier by equal volume impregnation method, and then reduced with absolute ethanol. The mass fraction of the active component Ru in the carrier was 4%, and the catalyst Ru / MgO was obtained. The catalyst is at 3MPa and the space velocity is 10000h -1 The activity of the catalyst is measured under the following conditions, and the activity of the...

Embodiment 2

[0036] Embodiment 2 (comparative example)

[0037] Zr(NO 3 ) 4 . 5H 2 O: Ba(NO 3 ) 2 : A mixture of citric acid: ethylene glycol molar ratio of 1:1:2:4 was dissolved in an appropriate amount of distilled water to obtain a colorless clear viscous liquid. The solution was slowly heated in a water bath at 80°C for 4h to evaporate excess water, and then heated at a constant temperature of 90°C for 12h to promote the gelation of the mixture. Finally, the obtained gel was calcined at 300 °C for 1 h to obtain the precursor, and then calcined at 750 °C for 3 h to obtain BaZrO 3 carrier material. The active component ruthenium is impregnated into the carrier by the equal volume impregnation method, and then reduced with absolute ethanol. The mass fraction of the active component Ru in the carrier is 4%, and the obtained catalyst is Ru / BaZrO 3 . The catalyst is at 3MPa and the space velocity is 10000h -1 The activity of the catalyst is measured under the following conditions, ...

Embodiment 3

[0039] Prepare 1:1 mixed oxide carrier by ultrasonic mixing method: weigh 19.3g of Mg(NO 3 ) 2 . 6H 2 O is put into a beaker, and an appropriate amount of distilled water is added to obtain a colorless and clear solution of magnesium nitrate, and the concentration of the substance is 1mol / L (NH 4 ) 2 CO 3 The solution was slowly added to the above magnesium nitrate solution, stirred at 40°C for 0.5h, after fully reacting, aged in the mother liquor for 1h, and weighed 3g of the BaZrO prepared in Example 2 3 Put the solid powder into the mortar and grind it, then add it to the above milky white suspension, and apply ultrasonic action for 40 minutes to make it evenly dispersed. After standing, aging, and centrifugal separation, the product after ultrasonic action is placed in an oven Dry at 90°C for 12 hours to obtain a bulk mixed carrier precursor. Finally, the obtained mixed carrier precursor was calcined at 300°C for 1 h to obtain the precursor, and then calcined at 750°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com