Device and process for removing hydrogen sulfide contained in industrial gas

An industrial gas and hydrogen sulfide technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem that the gas-phase interface cannot be quickly updated, the gas-film mass transfer coefficient changes little, and the relative slip velocity is small. and other problems, to achieve the effect of small gas phase pressure drop, high selectivity, and small liquid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

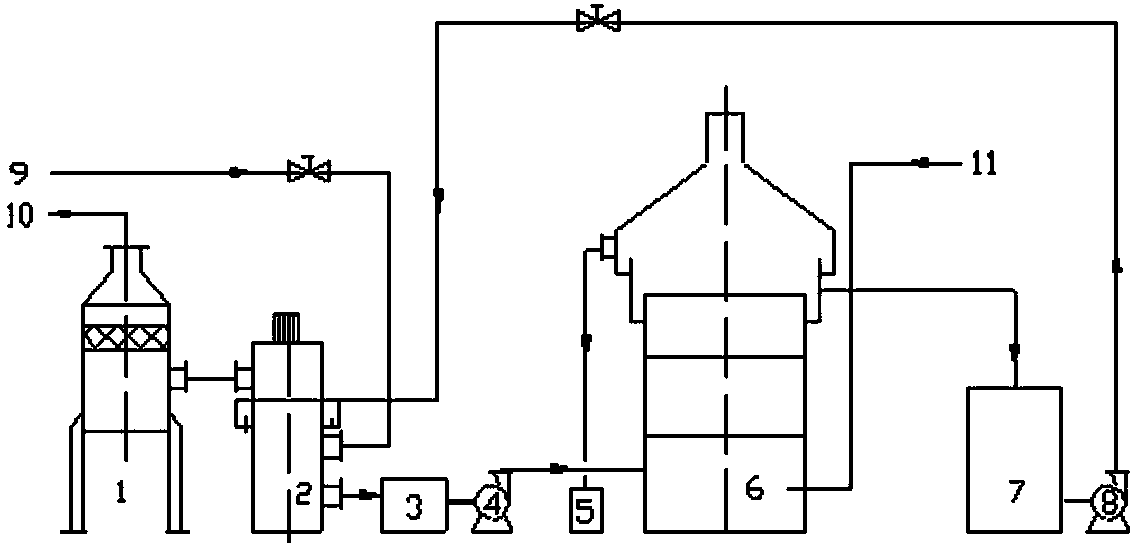

[0058] Removal of hydrogen sulfide from industrial gas: the gas volume to be treated in the process is 15000m 3 / h, hydrogen sulfide content is 1600mg / m 3 . Preparation of desulfurization liquid 140 m 3 , the total alkalinity of soda ash is 22g / L, the sodium carbonate is 0.2-0.6mol / L, the pH value is 7-10, the CoS catalyst is selected, and the concentration is 20-60ppm.

[0059] Turn on the supergravity rotary packed bed, and adjust the rotor speed of the rotary packed bed to 500r / min through the frequency converter. After the rotary packed bed is stable (about two minutes), open the liquid valve, start the lean liquid pump, and adjust the liquid volume to 100m 3 / h, turn on the rich liquid pump at the same time, after the liquid phase runs smoothly, turn on the gas phase, and gradually reach 15000m through the regulating valve 3 / h. The liquid phase system is heated through the steam pipeline, and the temperature is controlled at 30-50°C; the gas-liquid is absorbed in the...

Embodiment 2

[0061] Selective absorption of hydrogen sulfide in acidic systems in industrial syngas (CO 2 The volume content accounts for 96.6%, the volume content of hydrogen sulfide accounts for 0.78%, and the concentration is 10.6g / m 3 ), the gas volume to be treated in the process is 28000m 3 / h, hydrogen sulfide content is 10200mg / m 3 . First prepare the desulfurization liquid, the liquid volume is 300 m 3 / h, soda ash total alkalinity is 32g / L, and sodium carbonate is 0.1~0.4mol / L, and pH value is 7~10, selects DDS catalyst for use, and the different component concentrations of catalyst are prepared according to technological requirements, and all the other are with example 1. According to the characteristics of the short residence time of the rotating packed bed, the absorption of hydrogen sulfide by the desulfurization liquid is completed in an instant, thereby improving the selectivity of absorption, reducing side reactions, and reducing alkali consumption; after the process sy...

Embodiment 3

[0063] The amount of natural gas removal of hydrogen sulfide in natural gas is 15000m 3 / h, the concentration of hydrogen sulfide is 2400mg / m 3 . This process is under the condition that the desulfurization effect of the traditional tower equipment cannot meet the specified requirements, and the operating condition is that the liquid circulation volume is 200m 3 / h, the height of the tower is 32m, the diameter is 3.5m, and the removal rate is 75%. After adopting this new process, the diameter of the rotating packed bed is 2m, the height is 3m, and the liquid volume is 250m 3 / h, the total alkalinity of soda ash is 40g / L, the sodium carbonate is 0.1-0.5mol / L, the pH value is 7-10, the ADA catalyst is selected, and the concentration is 2-3g / L. After the process system is stabilized, the removal rate of hydrogen sulfide can reach more than 99%, and the outlet concentration of hydrogen sulfide is lower than 50mg / m 3,Compared with the traditional wet process, the equipment volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com