Optical anti-vibration motor

An optical anti-shake, motor technology, applied in the direction of optics, optical components, installation, etc., can solve problems such as uneven thrust, affecting picture quality, jitter, etc., and achieve the effect of improving stability and good anti-shake performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

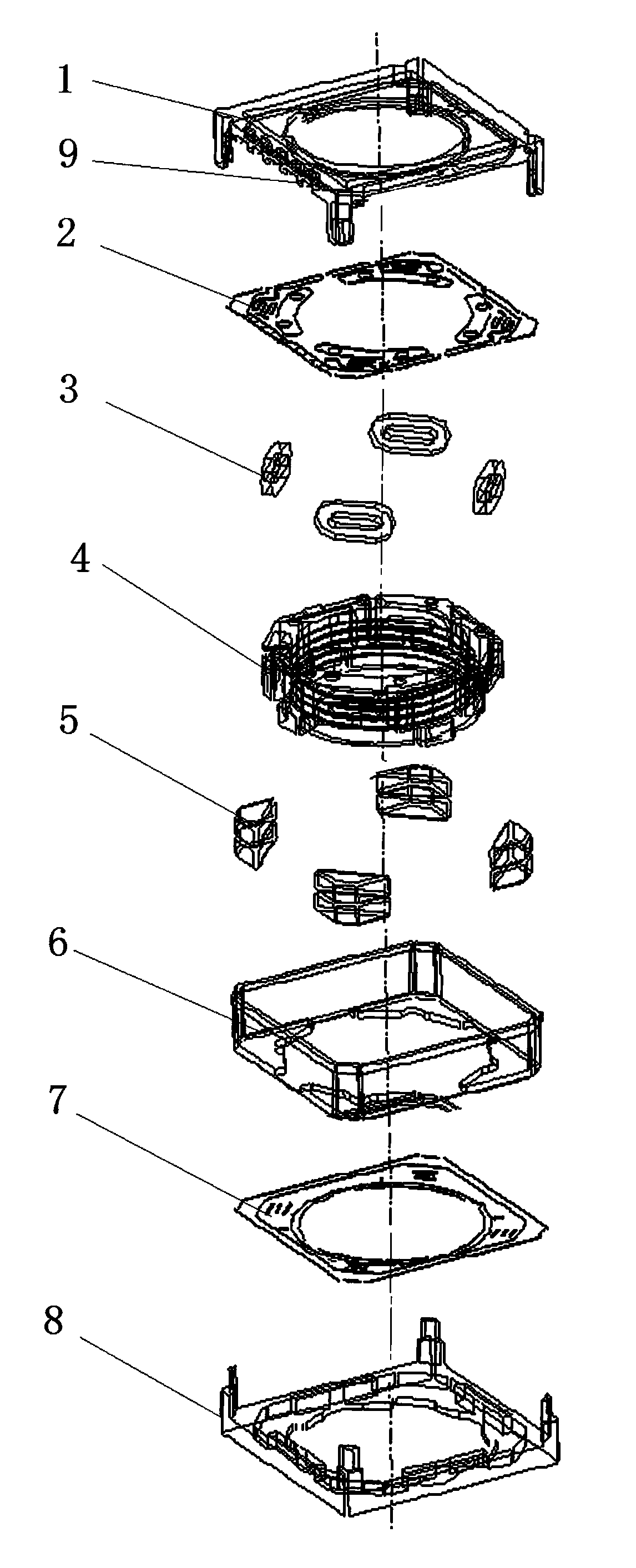

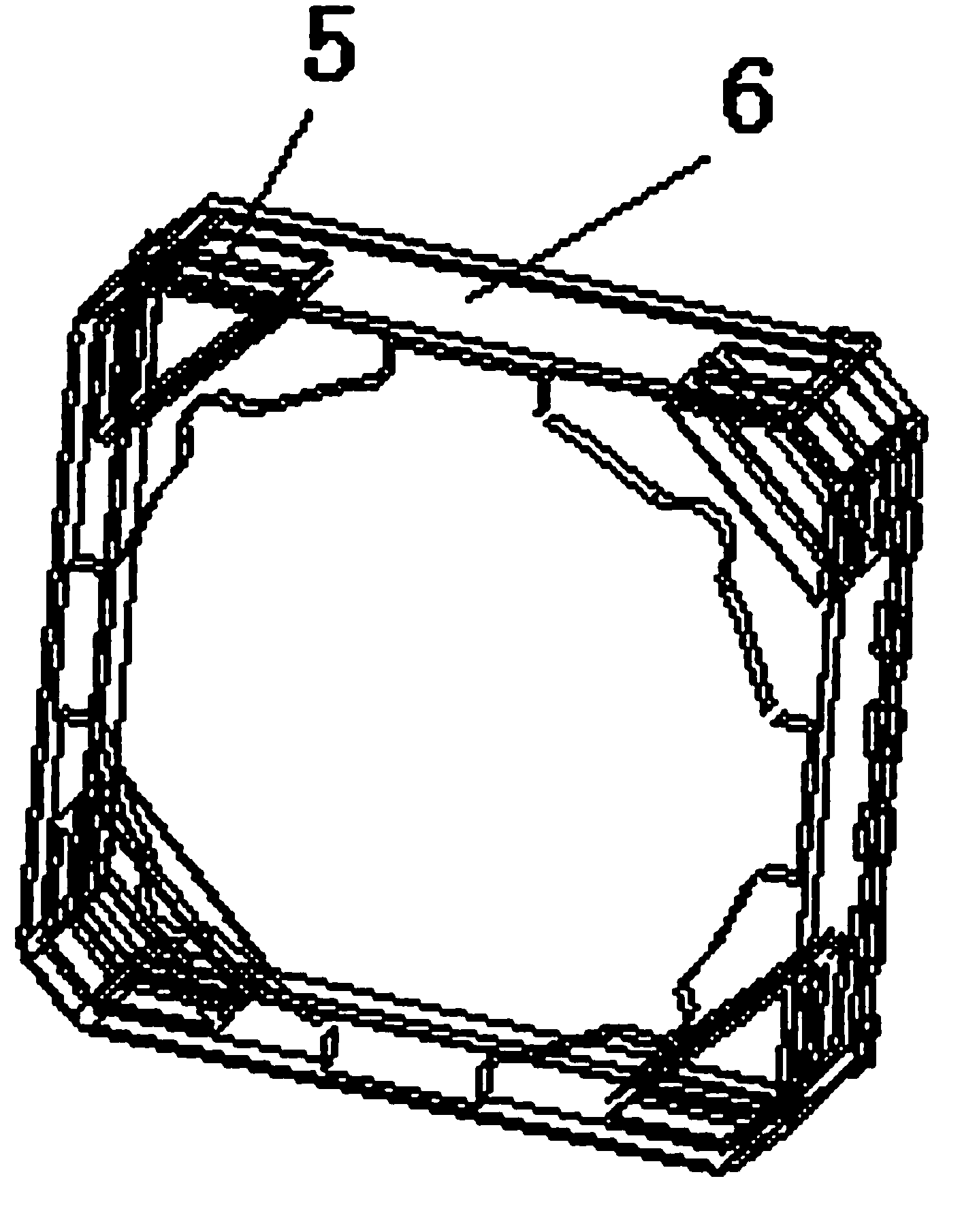

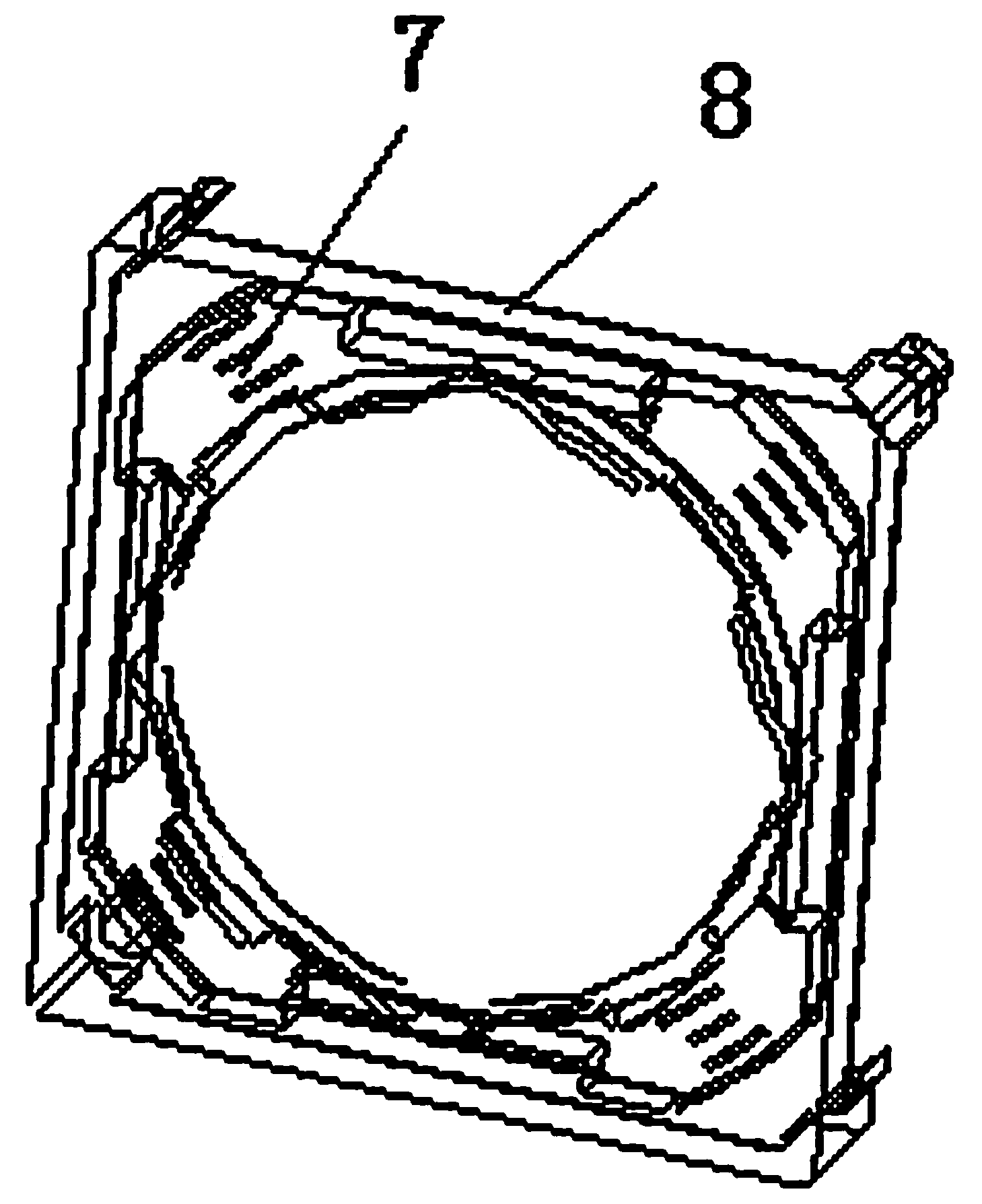

[0016] As shown in the figure, an optical anti-shake motor includes a base 1, a yoke iron shell 6 cooperating with the base 1, a magnet 5 and a lens carrier 4 wound with a coil 3 are arranged in the yoke iron shell 6, and the lens A rear reed 2 is provided between the carrier 4 and the base 1, and the yoke iron shell 6 is a square structure, which is characterized in that four groups of magnets 5 are arranged symmetrically on the yoke iron shell 6 of the square structure, and the outside of the lens carrier 4 Four coils 3 are arranged symmetrically, and each coil 3 corresponds to a group of magnets 5 . As shown in the figure, the coil is located between the magnet and the lens carrier 4, and the coil and the magnet are vertically arranged. There is also a PCB board 9 inside the base 1 , the PCB board 9 is provided with four control terminals, each contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com