Cationic polymer as well as preparation method and application thereof

A cationic polymer and polymer technology, applied in the direction of separation method, liquid separation, grease/oily substance/floating matter removal device, etc., can solve the problem of lack of demulsification and flocculation ability, low cationic degree of melamine resin, melamine Solve the problems of short resin storage period and achieve the effect of oil-water separation, large molecular weight and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

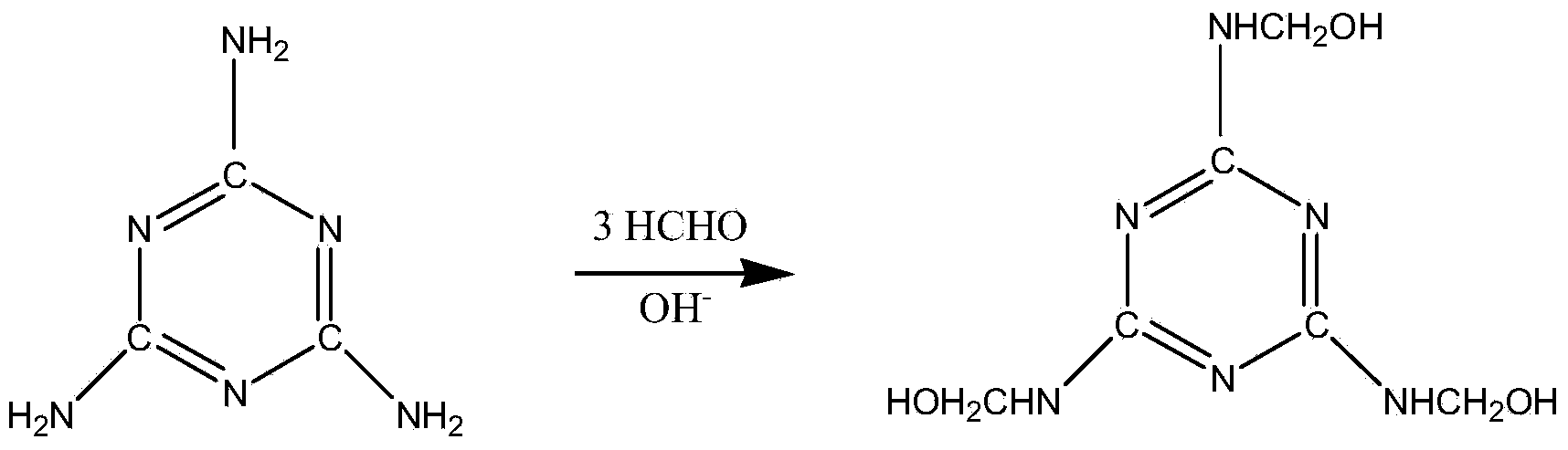

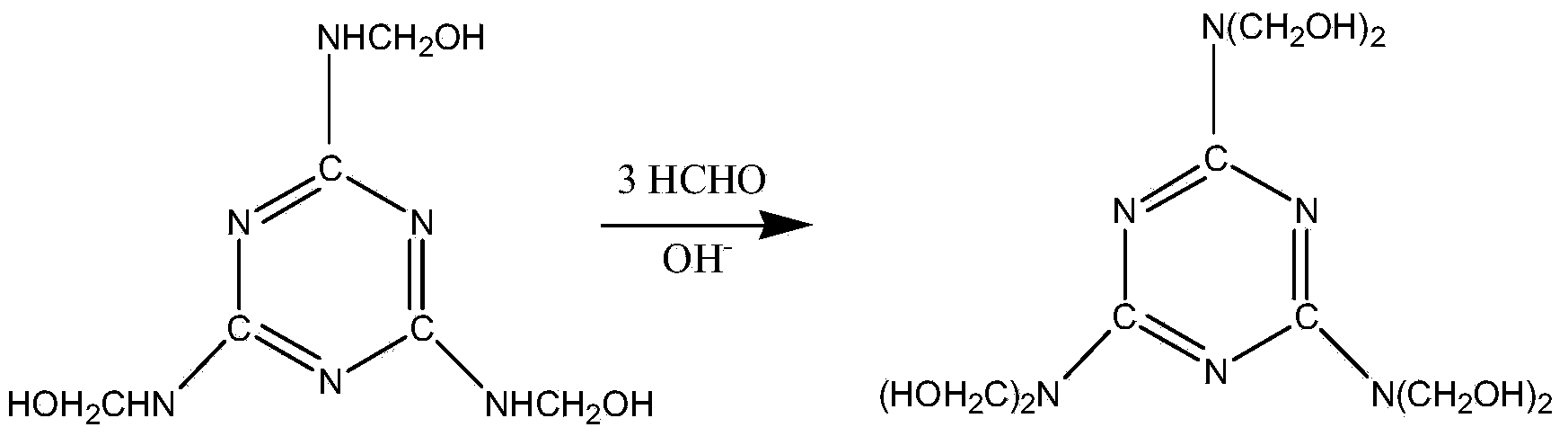

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a cationic polymer, which is prepared through five process steps of metering and mixing, methylol reaction, polycondensation reaction, polymerization inhibition reaction, and elimination of free formaldehyde, specifically as follows: add 400 parts by weight of The water is heated up to 60°C, and the pH is adjusted to 9 with an alkaline substance; then 40 parts by weight of melamine is added, 70 parts by weight of formaldehyde is added, the temperature is raised to 80°C, and the reaction is carried out for 40 minutes; The acidic substance adjusted the pH to 2, raised the temperature, and reacted at 85° C. for 4 hours; finally added 4 parts by weight of formaldehyde remover, and kept the reaction for 30 minutes to obtain a cationic polymer.

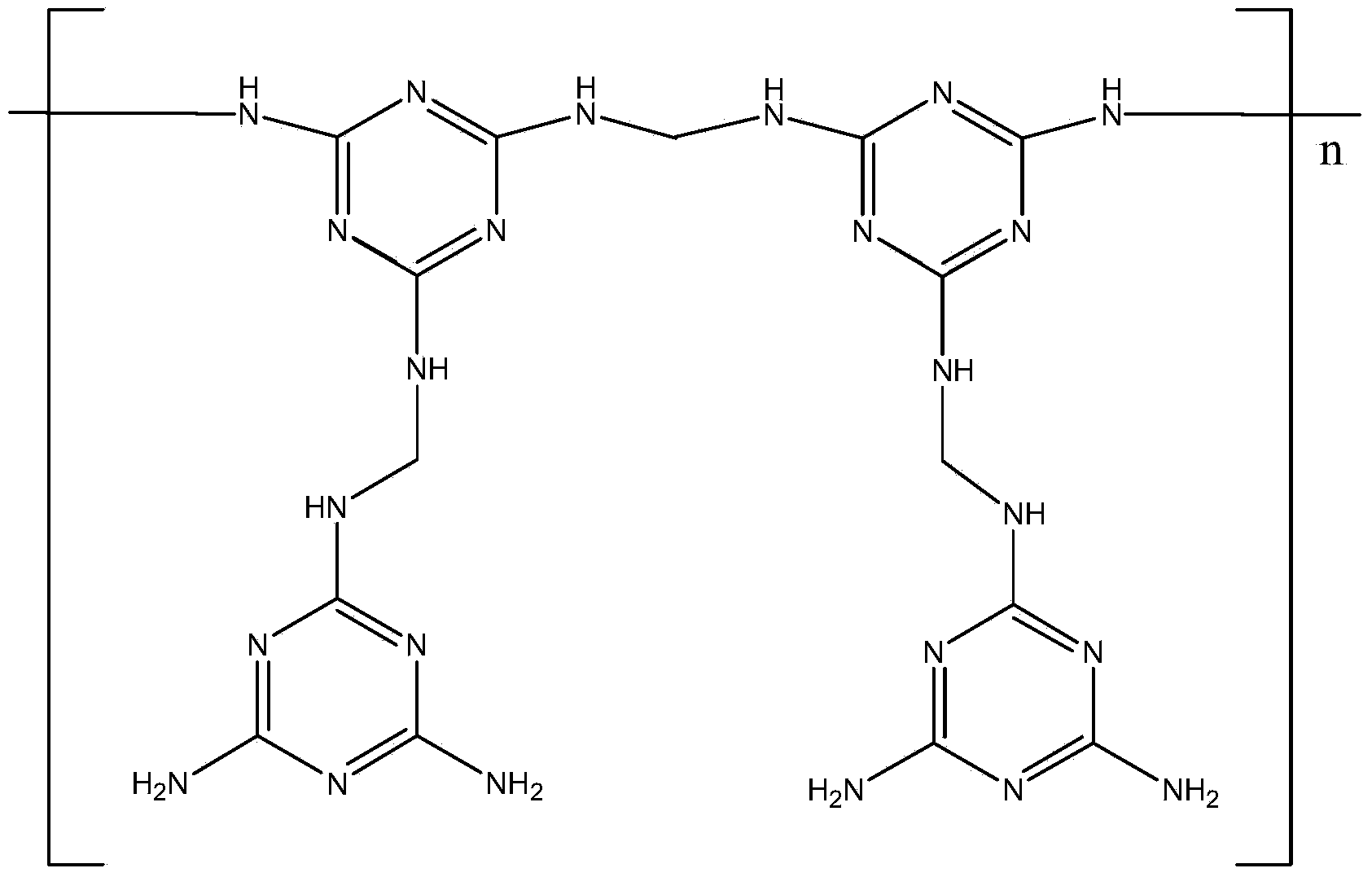

[0037] The cationic polymer prepared in this example has a structural formula such as Formula 1, n=5000, a cationic degree of 20%, and a density of 1.02 g / ml.

Embodiment 2

[0039] A method for preparing a cationic polymer, which is prepared through five process steps of metering and mixing, methylol reaction, polycondensation reaction, polymerization inhibition reaction, and elimination of free formaldehyde, specifically as follows: add 800 parts by weight of The water is heated up to 65°C, and the pH is adjusted to 9.5 with an alkaline substance; then 120 parts by weight of melamine is added, 240 parts by weight of formaldehyde is added, the temperature is raised to 85°C, and the reaction is carried out for 60 minutes; 12 parts by weight of a polymerization inhibitor is added, and the Adjust the pH to 4 with the acidic substance, raise the temperature, and react at 95° C. for 2 hours; finally add 12 parts by weight of formaldehyde remover, and keep the reaction for 1 hour to obtain a cationic polymer.

[0040] The cationic polymer prepared in this example has a structural formula such as formula 1, n=30000, a cationic degree of 28% and a density ...

Embodiment 3

[0042]A method for preparing a cationic polymer, which is prepared through five process steps of metering and mixing, methylol reaction, polycondensation reaction, polymerization inhibition reaction, and elimination of free formaldehyde, specifically as follows: add 900 parts by weight of water, adjust the pH to 8.5 with an alkaline substance; then add 60 parts by weight of melamine, add 110 parts by weight of formaldehyde, heat up to 70°C, and react for 60 minutes; add 5 parts by weight of a polymerization inhibitor, and adjust the pH to 3. Raise the temperature and react at 90° C. for 3 hours; finally add 8 parts by weight of formaldehyde remover and keep it warm for 60 minutes to obtain a cationic polymer.

[0043] The cationic polymer prepared in this example has a structural formula such as formula 1, n=12000, a cationic degree of 22% and a density of 1.03 g / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com