Reproducing method of main bearing hole of engine cylinder block assembly

A technology for engine cylinders and main bearings, which is used in manufacturing tools, honing machine tools, machine tools suitable for grinding workpiece planes, etc. The effect of mass production, improving processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

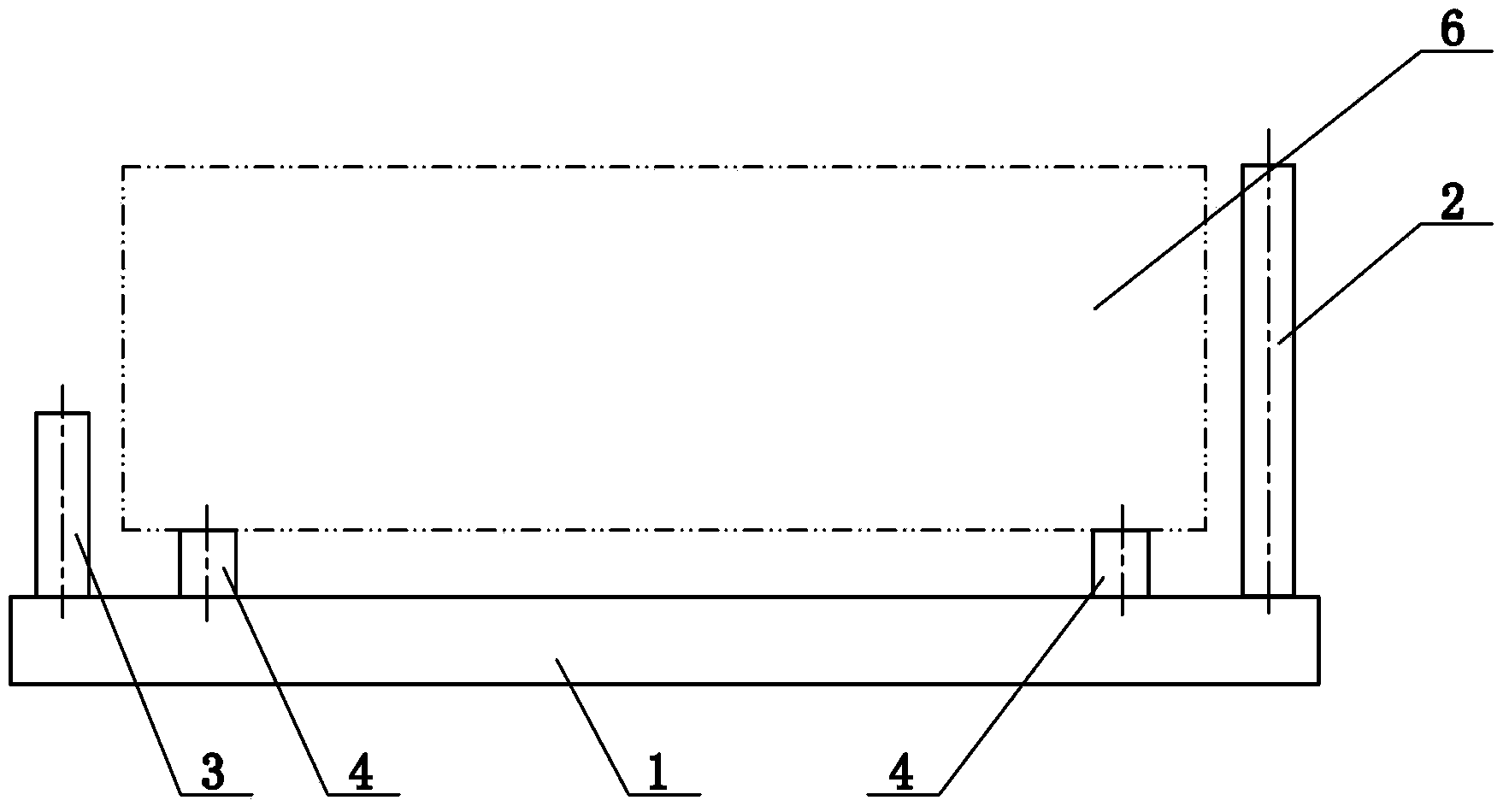

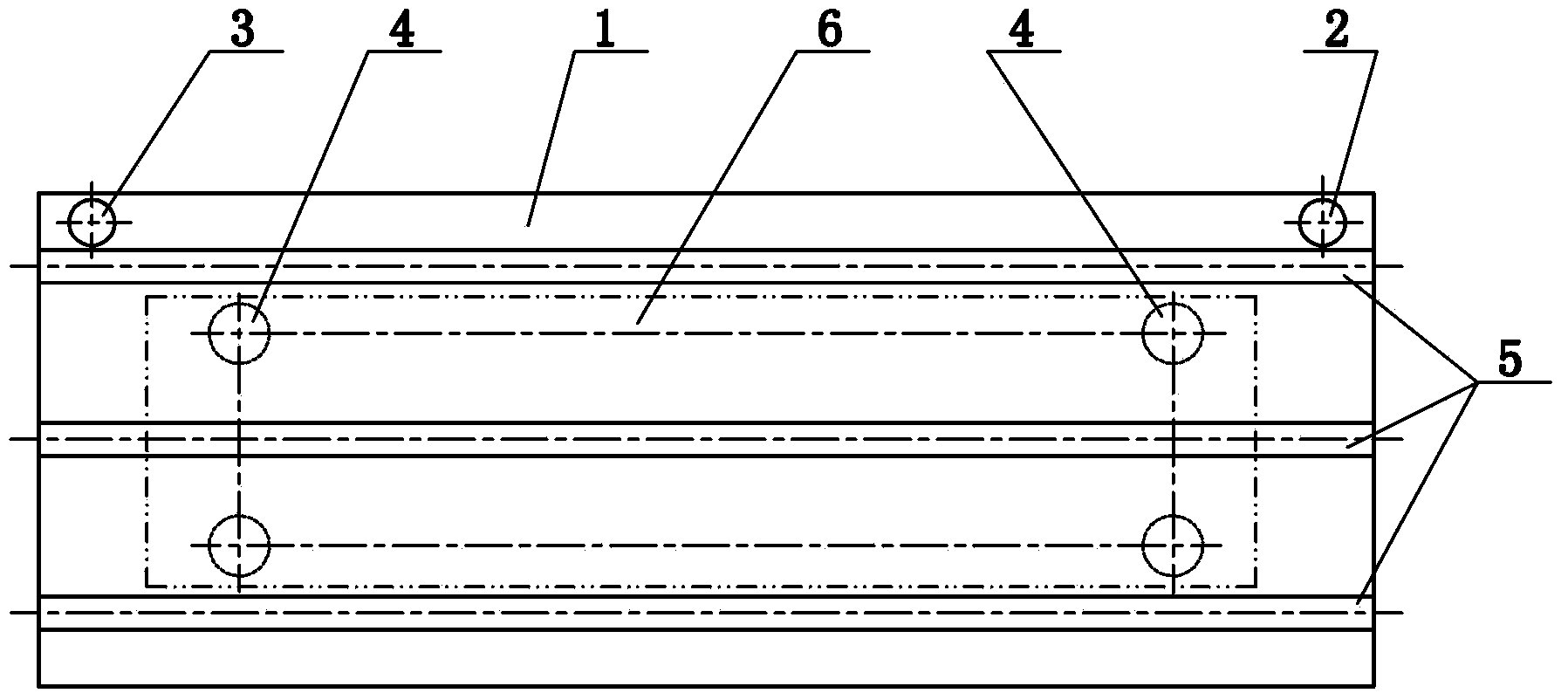

[0032] The method for remanufacturing the main bearing hole of the engine cylinder block assembly comprises the following steps:

[0033] (1) Machining of the joint surface of the main bearing seat of the cylinder block: Based on the joint surface of the main bearing seat of the cylinder block, use a surface grinder and tooling grinding to remove the processing amount of 0.02mm on the joint surface of the main bearing seat of the cylinder block, and ensure that the cylinder The shape and position tolerance requirements of the joint surface of the body main bearing seat;

[0034] (2) Machining of the joint surface of the main bearing seat of the crankcase: taking the joint surface of the main bearing seat of the crankcase as the benchmark, use a surface grinder and tooling to grind the joint surface of the main bearing seat of the crankcase to remove the processing amount of 0.02mm;

[0035] (3) Assembly: Assemble the cylinder block and crankcase according to the assembly seque...

Embodiment 2

[0038] The method for remanufacturing the main bearing hole of the engine cylinder block assembly comprises the following steps:

[0039](1) Machining of the joint surface of the main bearing seat of the cylinder block: Based on the joint surface of the main bearing seat of the cylinder block, use a surface grinder and tooling grinding to remove the processing amount of 0.05mm on the joint surface of the main bearing seat of the cylinder block, and ensure that the cylinder The shape and position tolerance requirements of the joint surface of the body main bearing seat;

[0040] (2) Machining of the joint surface of the main bearing seat of the crankcase: taking the joint surface of the main bearing seat of the crankcase as a reference, the machining amount of 0.05mm is removed by surface grinder and tooling grinding on the joint surface of the main bearing seat of the crankcase;

[0041] (3) Assembly: Assemble the cylinder block and crankcase according to the assembly sequence...

Embodiment 3

[0044] The method for remanufacturing the main bearing hole of the engine cylinder block assembly comprises the following steps:

[0045] (1) Machining of the joint surface of the main bearing seat of the cylinder block: taking the joint surface of the main bearing seat of the cylinder block as a reference, use a surface grinder and tooling grinding to remove the processing amount of 0.10mm on the joint surface of the main bearing seat of the cylinder block, and ensure that the cylinder The shape and position tolerance requirements of the joint surface of the body main bearing seat;

[0046] (2) Machining of the joint surface of the main bearing seat of the crankcase: taking the joint surface of the main bearing seat of the crankcase as a reference, use a surface grinder and tooling to grind away the processing amount of 0.10mm on the joint surface of the main bearing seat of the crankcase;

[0047] (3) Assembly: Assemble the cylinder block and crankcase according to the assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com