Magnet forming die

A technology for forming molds and magnets, which is applied in the field of molds, can solve the problems of low orientation of magnets and large magnetic declination angles of magnets, and achieve the effects of improving orientation, reducing magnetic declination angles, and reducing deflection angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

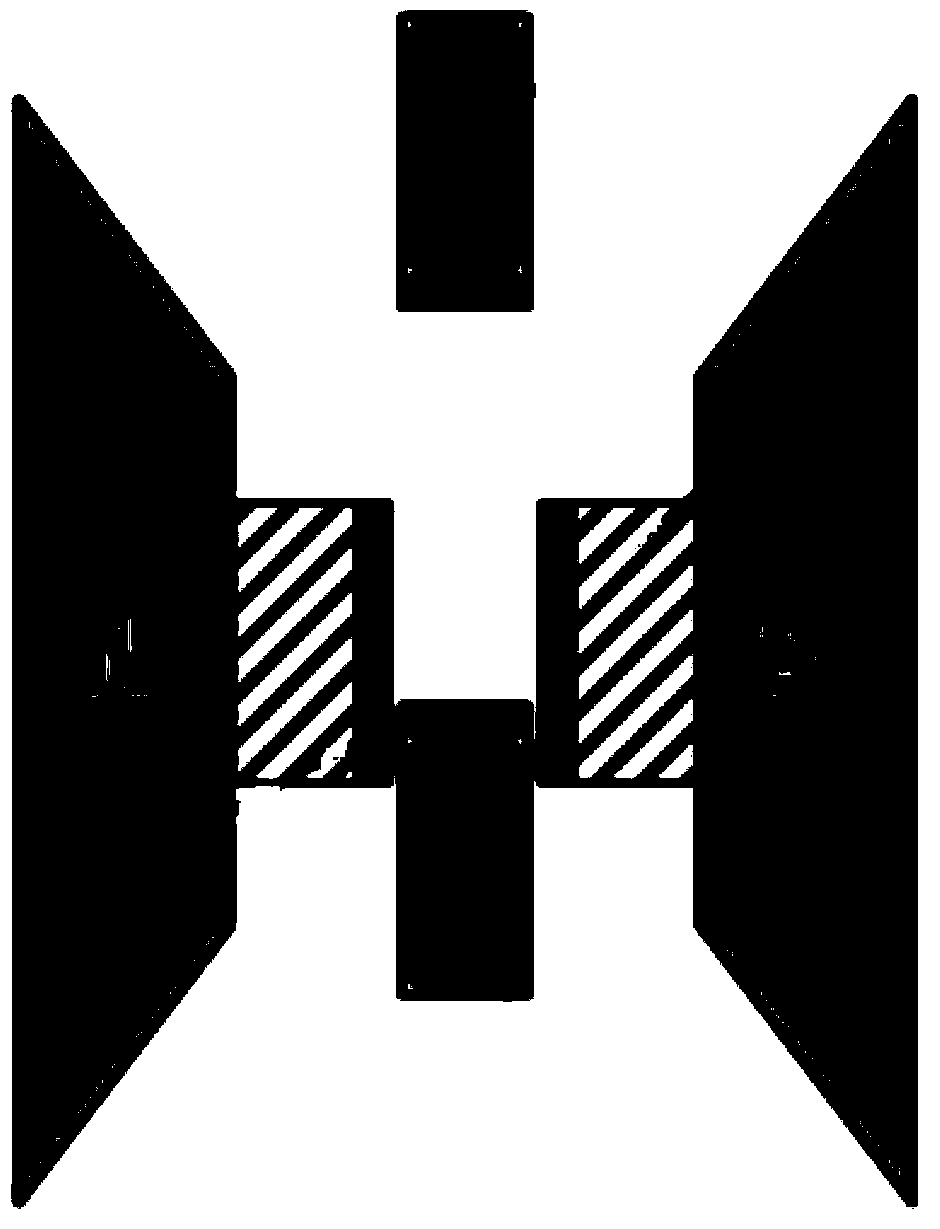

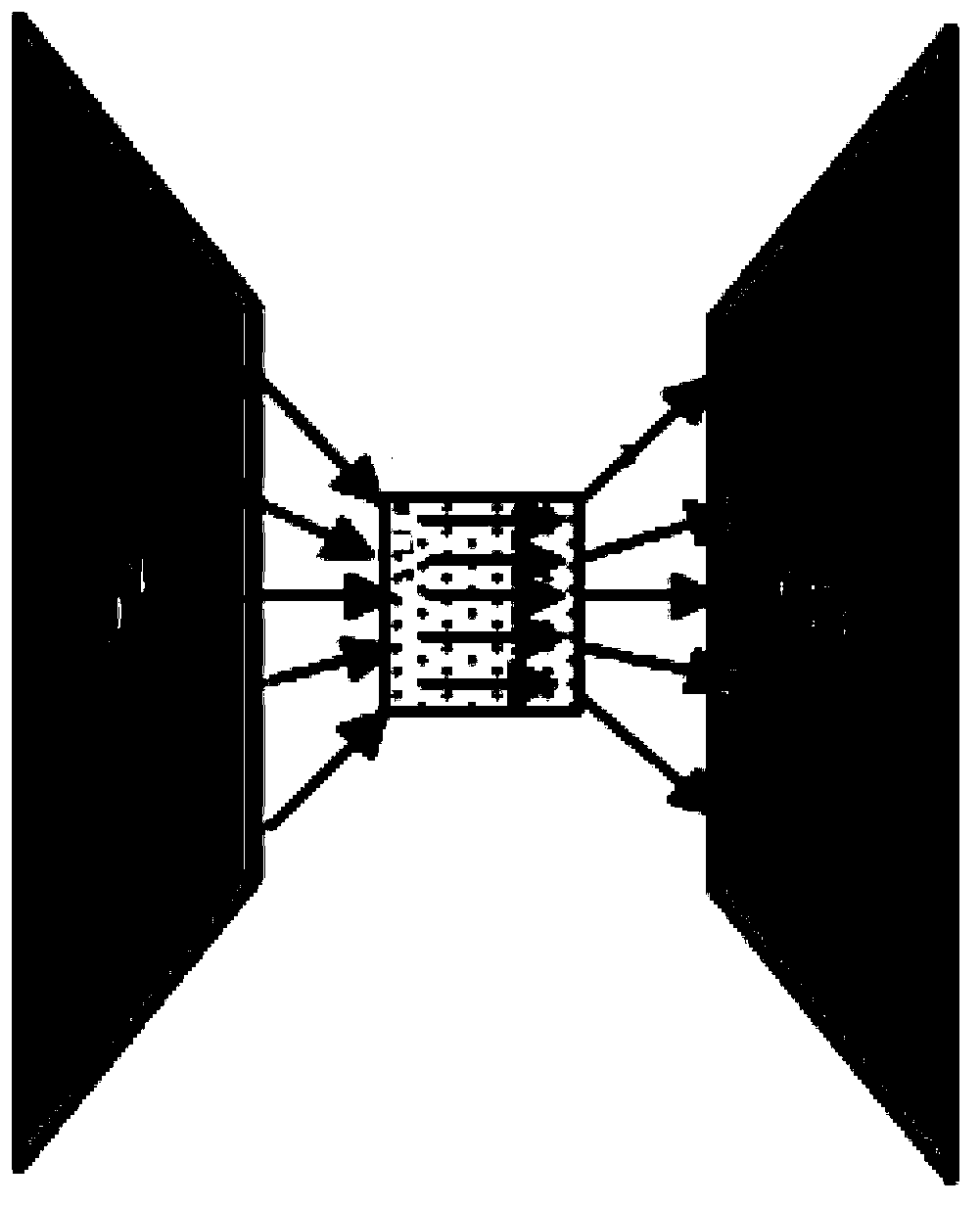

[0027] Example 1: In this example, it is necessary to prepare a sintered NdFeB square magnet. According to the design requirements of the sintered NdFeB square magnet, the size of the magnet compact is required to be 38.5mm×34mm×24.5mm, and 34mm represents the magnetic orientation direction of the magnet compact 38.5mm is the width of the magnet compact, 24.5mm is the thickness of the magnet compact in the pressing direction, and the loose magnetic powder density is 2.0g / cm 3 , the magnet compact density is 4.0g / cm 3 , we choose the size of the mold cavity to be 38.5mm×34mm×100mm, the demoulding angle is 1°, the cross-sectional dimensions of the upper punch 2 and the lower punch 3 are both 38.5mm×34mm, and the thickness of the carbide sleeve 12 is 15mm , the distance between the S pole head and the N pole head of the magnetic orientation device 4 is 140mm, and the inner end surface of the soft magnetic material block 15 is the same as the cross-sectional shape of the loose mag...

Embodiment 2

[0029] Example 2: In this example, it is necessary to prepare a sintered NdFeB VCM (voice coil motor) magnet. According to the design requirements of the sintered NdFeB VCM magnet, the cross-sectional shape of the magnet compact is as follows Figure 9 As shown, the size of the magnet compact is required to be 50mm×47.3mm×20.5mm, 50mm represents the length of the magnet compact in the direction of magnetic orientation, 47.3mm represents the width of the magnet compact, and 20.5mm represents the thickness of the magnet compact in the pressing direction. Magnetic powder density is 2.0g / cm 3 , the magnet compact density is 4.0g / cm 3 , we choose the size of the mold cavity to be 50mm×47.3mm×100mm, the demoulding angle is 1°, the cross-sectional dimensions of the upper punch 2 and the lower punch 3 are both 50mm×47.3mm, and the thickness of the carbide sleeve 12 is 10mm , The distance between the S pole head and the N pole head of the magnetic orientation device 4 is 140 mm. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com