Fe<3+>/Ag/TiO2/bamboo charcoal composite material and method for manufacturing cigarette filter tips by utilizing same

A technology of composite materials and bamboo charcoal, which is applied in the field of preparation of Fe3+/Ag/TiO2/bamboo charcoal composite materials, can solve problems such as no light source given, titanium dioxide crystal form for degradation not specified, reduction of photocatalytic activity of titanium dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

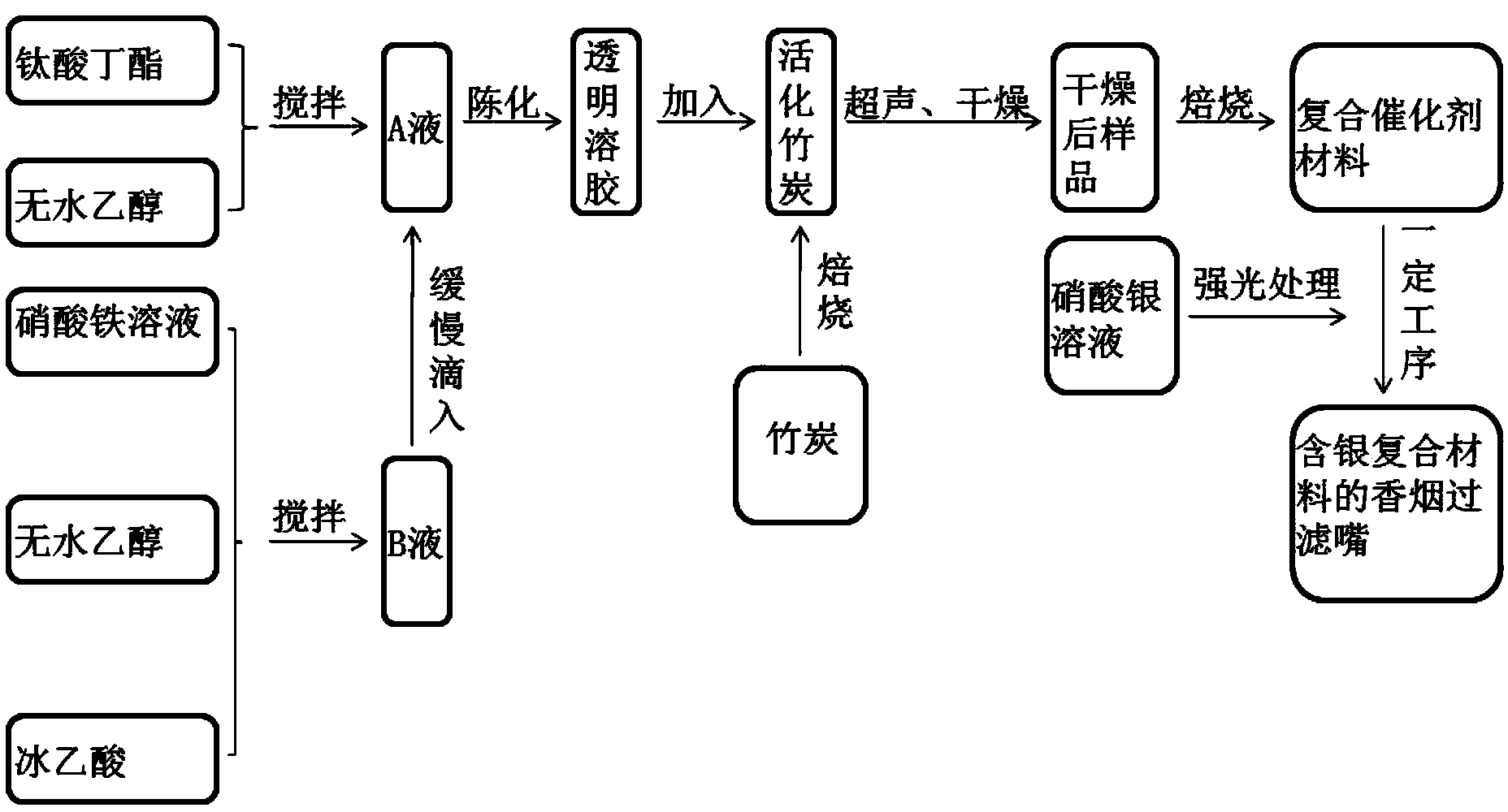

Method used

Image

Examples

Embodiment 1

[0025] Example 1: 1. Steps for preparing activated bamboo charcoal: roasting a certain amount of bamboo charcoal in an oxygen-free environment at 100-200°C for 2 hours to obtain activated bamboo charcoal for use; 2. 1 part of butyl titanate, 3 parts of absolute ethanol Add the volume ratio of 0.3 parts of ferric nitrate solution with a concentration of 0.21mol / L, 1 part of absolute ethanol, and 0.5 parts of glacial acetic acid into a dry container and stir evenly to make A solution. Stir evenly in a clean container to make solution B; ③. Slowly add solution B to solution A, stir while adding, continue stirring for about 30 minutes after the dropwise addition is completed to form a stable sol, and age the sol for about 5 hours for use; ④ 1. After putting the activated bamboo charcoal prepared in step ① into the aging sol prepared in step ③, treat it under ultrasonic conditions with a frequency of 45KHz at 32°C for 1h to make the sol enter the internal pores of the bamboo charcoa...

Embodiment 2

[0026] Example 2: 1. Steps for preparing activated bamboo charcoal: roasting a certain amount of bamboo charcoal in an oxygen-free environment at 100-200°C for 2 hours to obtain activated bamboo charcoal for use; 2. 1 part of butyl titanate, 3 parts of absolute ethanol Add the volume ratio of 0.4 parts of ferric nitrate solution with a concentration of 0.21mol / L, 1 part of absolute ethanol, and 0.5 parts of glacial acetic acid into a dry container and stir evenly to make A solution. Stir evenly in a clean container to make solution B; ③. Slowly add solution B to solution A, stir while adding, continue stirring for about 30 minutes after the dropwise addition is completed to form a stable sol, and age the sol for about 5 hours for use; ④ 1. After putting the activated bamboo charcoal prepared in step ① into the aging sol prepared in step ③, treat it under ultrasonic conditions with a frequency of 45KHz at 32°C for 1h to make the sol enter the internal pores of the bamboo charcoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com