Preparation method of dry gas hydrogen production preconversion catalyst

A catalyst and pre-conversion technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low-temperature reduction performance, poor low-temperature activity, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

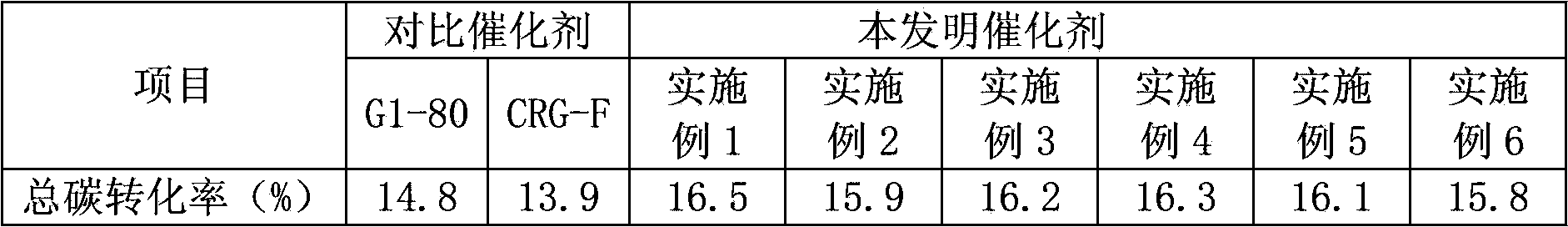

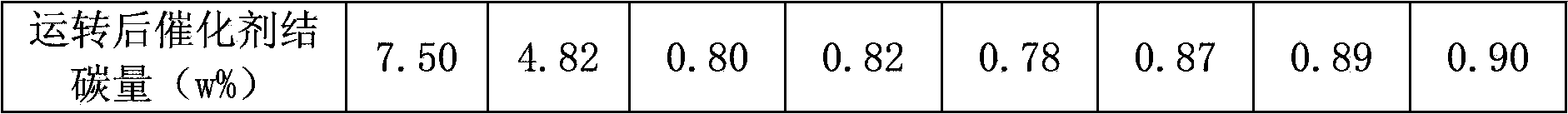

Examples

Embodiment 1

[0015] The weight ratio of each component of the prereforming catalyst in this embodiment is shown in Table 1 below:

[0016] Table 1 Embodiment 1 catalyst composition

[0017] components

NiO

MgO

Al 2 o 3

La 2 o 3

MO X

Proportion

35

15

45

2

3

[0018] (1) Preparation of reactant raw materials:

[0019] A. First, weigh 18g of aluminum hydroxide and 3g of heavy magnesium oxide, perform ball milling and mixing for 1.5hr-2hr, and then roast at a high temperature of 1100°C-1300°C for 2hr-4hr to prepare the carrier.

[0020] B, 260g / L Ni(NO 3 ) 2 Solution 25ml, M(NO 3 ) x (M is one or more of Zr, Y, Ag, Co, Cu, Zn, K) salt 1.8g, 360g / L La(NO 3 ) 2 Solution 1.2ml, the three solutions are mixed for use;

[0021] C. Na 2 CO 3 Solution configuration: saturated sodium carbonate solution for use.

[0022] (2) Neutralize precipitation:

[0023] A. In a water bath at 40°C±5°C, add the B and C solu...

Embodiment 2

[0035] The weight ratio of each component of the prereforming catalyst in this embodiment is shown in Table 2 below:

[0036] Table 2 Embodiment 2 catalyst composition

[0037] components

NiO

MgO

Al 2 o 3

La 2 o 3

MO X

Proportion

40

10

45

2

3

[0038] (1) Preparation of reactant raw materials:

[0039] A. First, weigh 18g of aluminum hydroxide and 2g of heavy magnesium oxide, perform ball milling and mixing for 1.5hr-2hr, and then roast at a high temperature of 1100°C-1300°C for 2hr-4hr to prepare the carrier.

[0040] B, 260g / L Ni(NO 3 ) 2 Solution 30ml, M(NO 3 ) x Salt 1.8g, 360g / L La(NO 3 ) 2 Solution 1.2ml, the three solutions are mixed for use;

[0041] C. Na 2 CO 3 Solution configuration: saturated sodium carbonate solution for use.

[0042] (2) Neutralize precipitation:

[0043]A. In a water bath at 40°C±5°C, add the B and C solutions configured in (1) into the reactor side-by...

Embodiment 3

[0055] The weight ratio of each component of the prereforming catalyst in this embodiment is shown in the following table 3:

[0056] Table 3 Embodiment 3 Catalyst Composition

[0057] components

NiO

MgO

Al 2 o 3

La 2 o 3

MO X

Proportion

45

10

40

2

3

[0058] (1) Preparation of reactant raw materials:

[0059] A. First, weigh 12g of aluminum hydroxide and 2g of heavy magnesium oxide, perform ball milling and mixing for 1.5hr-2hr, and then roast at a high temperature of 1100°C-1300°C for 2hr-4hr to prepare the carrier.

[0060] B, 260g / L Ni(NO 3 ) 2 Solution 40ml, M(NO 3 ) x Salt 1.8g, 360g / L La(NO 3 ) 2 Solution 1.2ml, the three solutions are mixed for use;

[0061] C. Na 2 CO 3 Solution configuration: saturated sodium carbonate solution for use.

[0062] (2) Neutralize precipitation:

[0063] A. In a water bath at 40°C±5°C, add the B and C solutions configured in (1) into the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com