A gas absorption system and its application

A gas absorption and absorption tower technology, which is used in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low absorption efficiency, explosion risk, and inability to automate gas control, and achieves reduction of emissions and work intensity. , the effect of easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

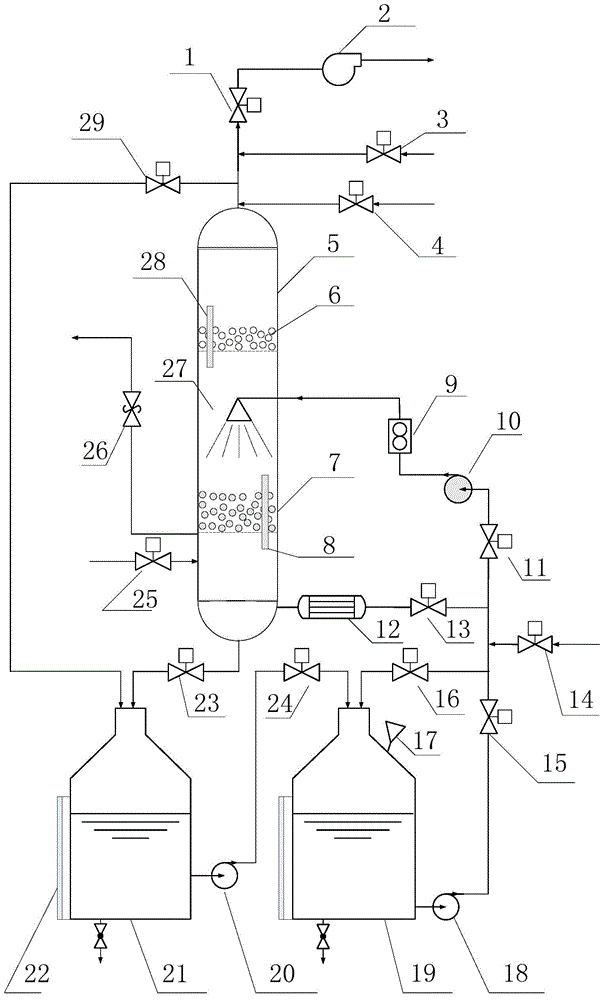

[0031] Example 1: Gas Absorption System

[0032] Including absorption tower 5, lye tank 19, secondary liquid tank 21, gas pipeline 25 to be absorbed; the top of the absorption tower is provided with a pipeline, which is connected with an emptying pipeline (fan 2 is arranged on the emptying pipeline), argon gas The pipeline 3, the clear water pipeline 4 and the overflow pipe 29; the overflow pipe 29 is connected to the secondary liquid tank 21; the positions of the emptying pipeline, the non-oxidizing gas pipeline, the water pipe and the overflow pipe are sequentially from top to bottom.

[0033] The absorption tower 5 is equipped with dispersed packing 7 (randomly stacked Pall rings) and defoaming packing 6 (random corrugated plate packing), and the defoaming packing 6 is located above the dispersed packing 7, and a spray nozzle 27 is arranged between the two packings , the nozzle is connected to the lye tank 19. The secondary liquid tank 21 is connected to the lye tank 19 th...

Embodiment 3

[0057] System and steps are the same as in Example 2.

[0058] Use it for nuclear fuel UO 2 The specific coating process of particles, that is, H 2 Alkali absorption process of mixed gas with HCl. It is measured that the gas to be absorbed is H containing 35% (volume fraction) of hydrogen chloride (HCl) gas 2 Mixed gas with HCl, the gas velocity is 110L / min. Saturated NaOH solution is prepared in the lye tank, PH=14. During normal absorption operation, the lye circulation rate is 25L / min, the absorption efficiency is more than 95%, and the HCl content in the exhaust gas is less than 1% (volume fraction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com