Circulating hydrogenation reactor

A technology of hydrogenation reactor and reaction, applied in chemical/physical/physical chemical nozzle reactor, detailed information of chemical/physical/physical chemical reactor, chemical instruments and methods, etc. Good control, excessive hydrogenation and other problems, to achieve the effect of improving performance, increasing disturbance, and increasing hydrogenation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

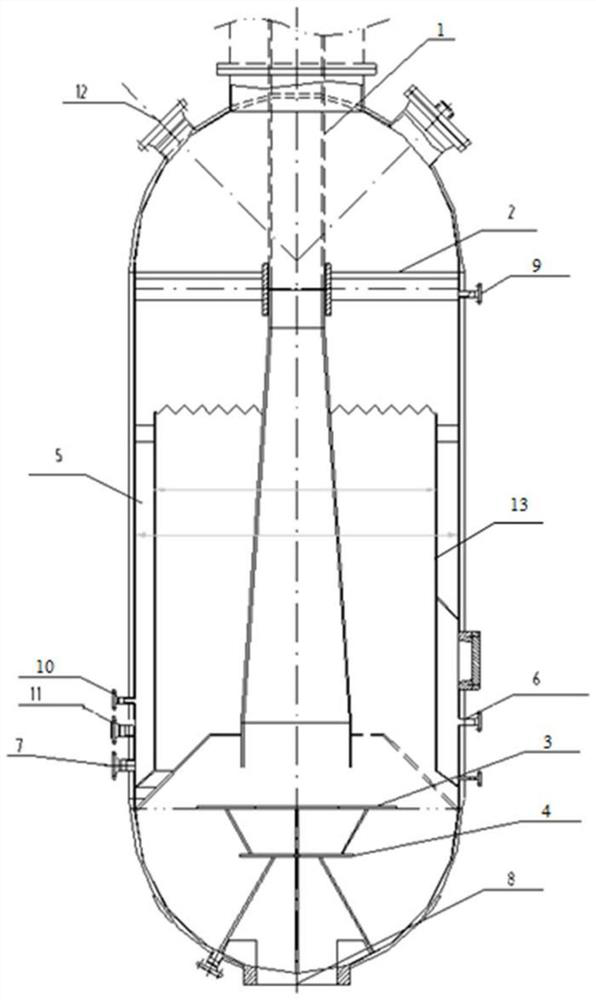

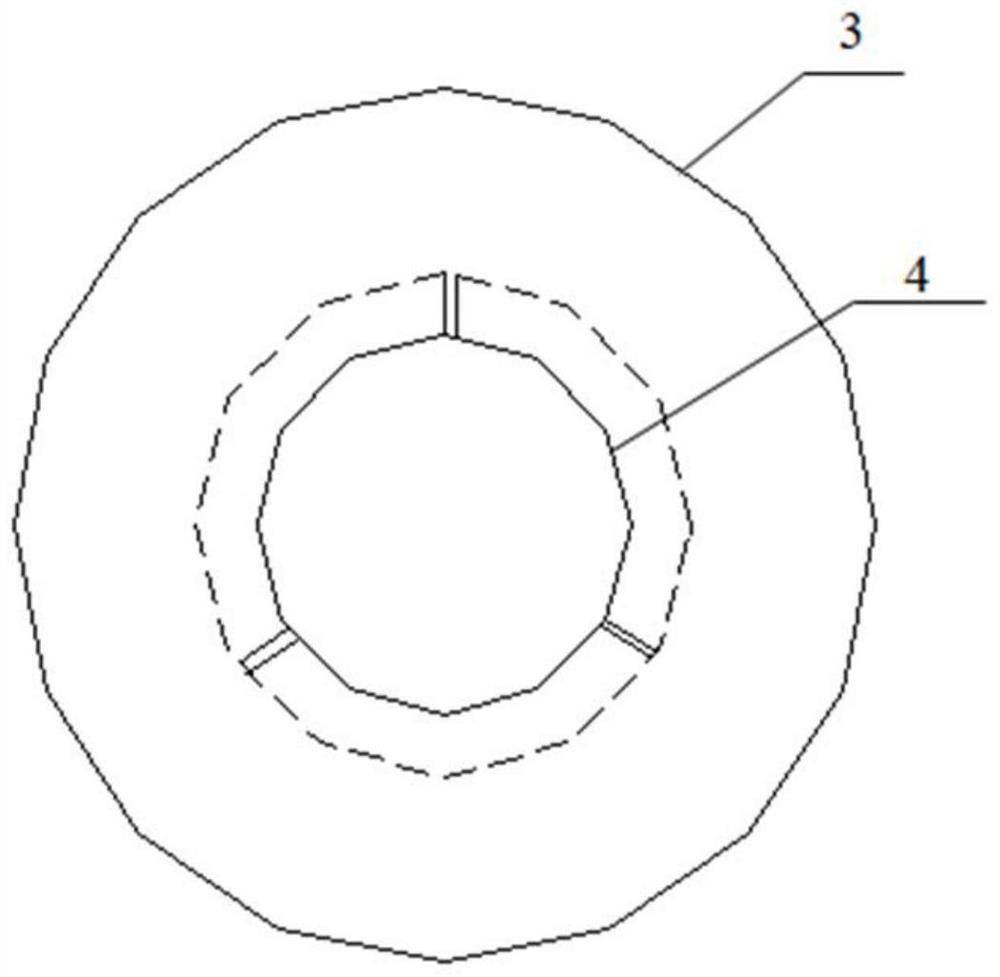

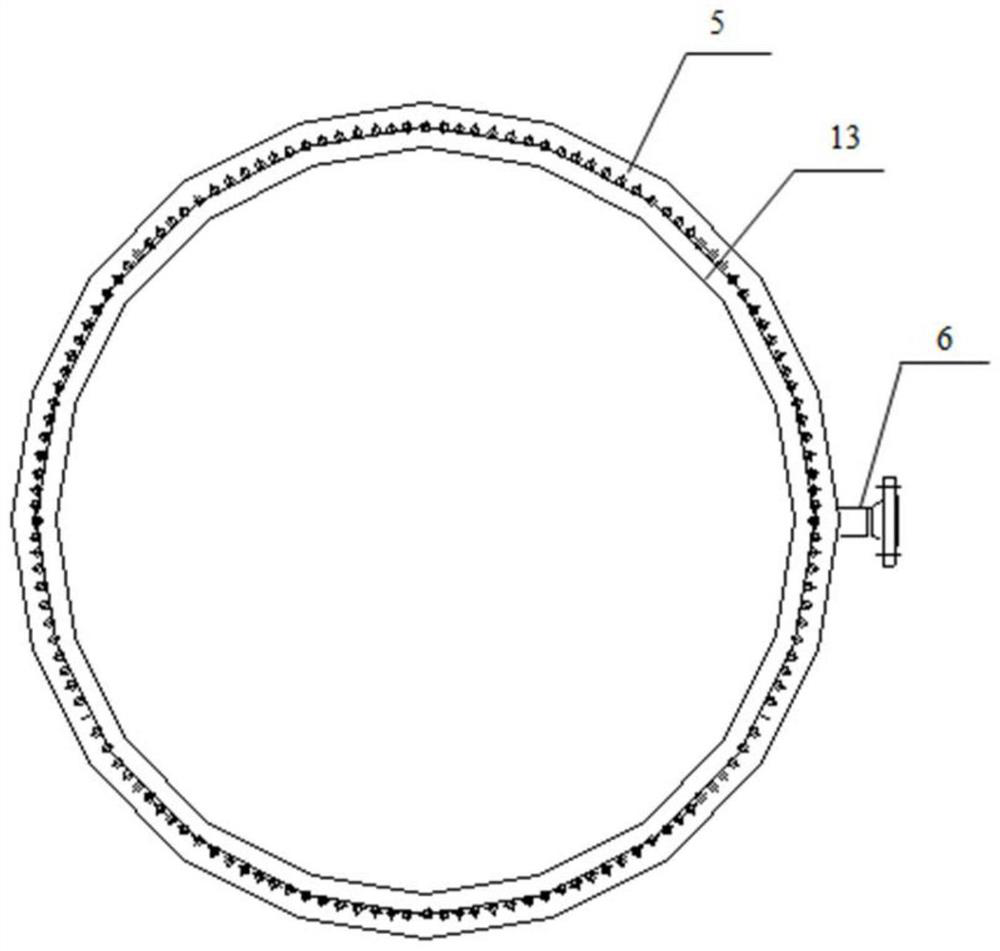

[0053] A kind of circulating hydrogenation reactor provided in this embodiment, see figure 1 , An interlayer 5 with an upper opening is formed between the jacket 13 and the inner wall of the tank. When in use, hydrogen and glue are added to the interior of the hydrogenation reactor through the nozzle 1, and the nozzle 1 is fixed by the support frame 2. In the nozzle 1, the hydrogen and the glue are fully mixed, and impact on the upper baffle 3 at the bottom, and a part of the material impacts on the lower baffle 4. The upper baffle 3 is designed in a circular shape. The purpose of setting the anti-shock baffle assembly is In order to increase the disturbance and improve the hydrogenation rate, the structure of the anti-shock baffle assembly is detailed in figure 2 . The material continuously enters the hydrogenation reactor and undergoes a reaction. The reaction material after the first reaction enters the interlayer 5 of the hydrogenation reactor, and the hydrogen gas separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com