Construction method of tissue engineering epidermis model

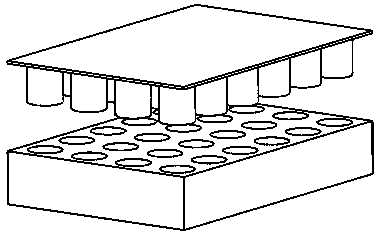

A tissue engineering and construction method technology, applied in tissue culture, biochemical equipment and methods, medical science, etc., can solve problems such as detection fluid leakage, achieve good mechanical properties, ensure mechanical strength, and good adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Polypropylene melt-blown non-woven fabric, hot-pressed at 140°C into a disc shape.

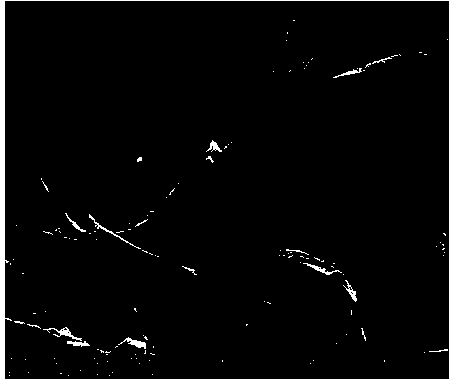

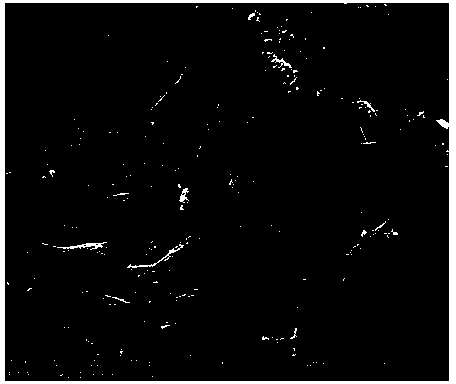

[0030] Commercially available mulberry silk, immersed in 60°C Na 2 CO 3 degumming in aqueous solution, Na 2 CO 3 The concentration of the aqueous solution is 0.2%, 30 minutes each time, 3 times in total, and dried at 70°C after washing with water. Dissolve in a ternary solution of CaCl2, ethanol, and water at 60°C (molar ratio 1:2:8), the dissolution time is 2 hours, put it into a dialysis bag, and dialyze under running water. A silk fibroin solution with a concentration of 3% was obtained. Soak the disc-shaped non-woven fabric in the silk fibroin solution, take it out, dry it in vacuum, and post-treat it with absolute ethanol, with 10 4 / ml Hacat cells were inoculated, cultured on the air-liquid surface, and the tissue engineering epidermal model was constructed. figure 2 is the electron micrograph of the blank scaffold without seeding cells, image 3 It is an electron microgra...

Embodiment 2

[0032] Polyethylene and polypropylene two-component melt-blown non-woven fabric, hot-pressed at 130°C into a disc shape.

[0033] Commercially available mulberry silk is immersed in a neutral soap solution at 90-100°C for degumming, washed with water and then dried at 70°C. Dissolved in CaCl at 95°C 2In the aqueous solution, the dissolution time is 10 minutes, put into a dialysis bag, and dialyze under running water washing. A silk fibroin solution with a concentration of 6% was obtained. Soak the disc-shaped non-woven fabric in the silk fibroin solution, take it out, dry it in vacuum, and post-treat it with absolute ethanol, with 10 4 / ml Hacat cells were inoculated, cultured on the air-liquid surface, and the tissue engineering epidermal model was constructed.

Embodiment 3

[0035] Polyamide spun-bonded non-woven fabric, heat-pressed at 200°C into disc shape.

[0036] Commercially available mulberry silk was degummed by immersing in deionized water under high temperature and pressure, washed with water and dried at 70°C. Dissolved in CaCl at 70°C 2 , ethanol, and water in a ternary solution (molar ratio 1:2:8), the dissolution time is 4 hours, put into a dialysis bag, and dialyze under running water. A silk fibroin solution with a concentration of 9% was obtained. Soak the disc-shaped non-woven fabric in the silk fibroin solution, take it out, dry it in vacuum, and post-treat it with absolute ethanol, with 10 5 / ml Hacat cells were inoculated, cultured on the air-liquid surface, and the tissue engineering epidermal model was constructed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com