Production process of compound wine for tonifying kidney and producing sperms of men and improving memory

A technology that acts on and prepares wine, and is applied to the production technology field of wine preparation. It can solve the problems of less dissolution of active ingredients, single ingredients, poor health care function, etc., and achieve the effects of enhancing brain memory, preventing deposition, and slowing heart rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

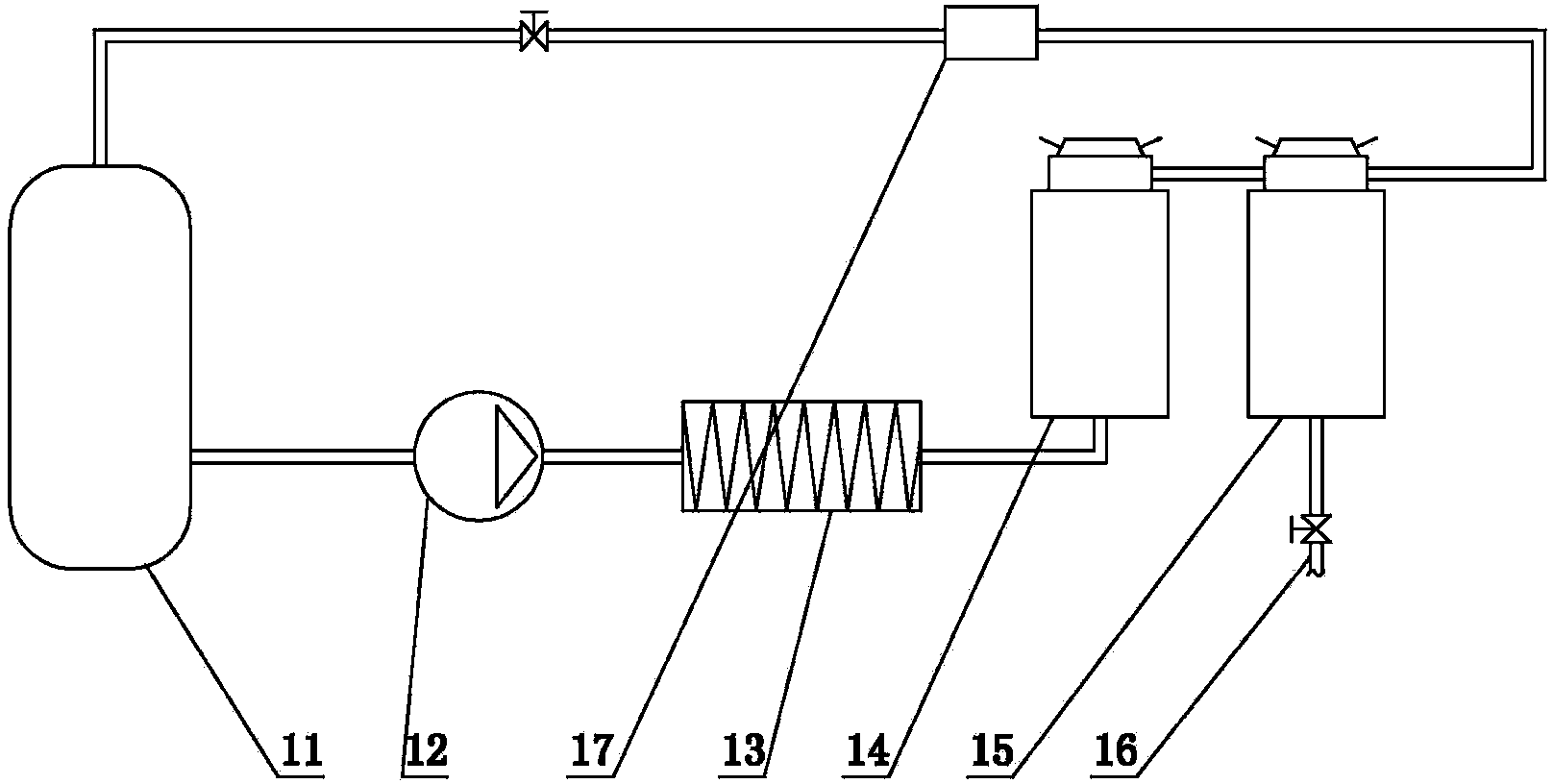

Image

Examples

Embodiment 1:30(1,)、30,30,30,15,20,20,50,30,20,30,20,30 to 40,; 2 ,,15L/min10Mpa、35℃CO2,CO2,CO2,, to ; to (36%vol),、30, and 。 Embodiment 2

[0013] Example 1: 30 parts of Alisma (1 gram per part, the same below), 30 parts of Shouwu, 30 parts of raw hawthorn, 30 parts of Polygonatum japonica, 15 parts of Curcuma, 20 parts of fried malt, 20 parts of fried rice sprouts 50 parts of Epimedium, 30 parts of Cistanche deserticola, 20 parts of Shayuanzi, 30 parts of Polygonatum chinensis, 20 parts of Salvia miltiorrhiza, 30 parts of Lycium barbarum respectively crushed to 40 mesh fineness granules, and mixed with appropriate amount of water according to the stated weight ratio ; Put the pellets into the extraction kettle of the supercritical carbon dioxide extractor, use an ethanol entrainer, and feed the CO with a pressure of 10Mpa and a temperature of 35 ℃ into the extraction kettle with a flow rate of 15L / min. 2 Extraction is carried out, and the CO saturated with dissolved substances after extraction 2 It is sent to the separator for separation, so that the extract can be separated from CO 2 Precipitate in the middle, ...

Embodiment 3

[0014] Example 3: 138 parts of Alisma, 138 parts of Shouwu, 138 parts of raw hawthorn, 138 parts of Polygonatum vulgaris, 49 parts of Curcuma, 92 parts of fried malt, 92 parts of fried grain bud, 210 parts of Epimedium, Cistanche 138 parts, Sha Yuanzi 92 parts, Polygonatum chinensis 138 parts, Salvia miltiorrhiza 92 parts, Lycium barbarum 138 parts are respectively crushed to the granular material of 40 mesh fineness, add appropriate amount of water to mix according to the described weight ratio; put the granular material into supercritical carbon dioxide In the extraction kettle of the extraction machine, an ethanol entrainer was used to feed CO with a pressure of 20Mpa and a temperature of 45°C into the extraction kettle at a flow rate of 22.5L / min. 2 Extraction is carried out, and the CO saturated with dissolved substances after extraction 2 It is sent to the separator for separation, so that the extract can be separated from CO 2 Precipitate in the middle, filter the extr...

Embodiment 4

[0015] Example 4: 192 parts of Alisma, 192 parts of Shouwu, 192 parts of raw hawthorn, 192 parts of Polygonatum vulgaris, 66 parts of Curcuma, 128 parts of fried malt, 128 parts of fried grain bud, 290 parts of Epimedium, Cistanche deserticola 192 parts, 128 parts of Shayuanzi, 192 parts of Polygonatum chinensis, 128 parts of Salvia miltiorrhiza, and 192 parts of wolfberry fruit were respectively crushed to 40 mesh fineness granules, and mixed with an appropriate amount of water according to the described weight ratio; the granules were put into supercritical carbon dioxide In the extraction kettle of the extraction machine, an ethanol entrainer was used to feed CO with a pressure of 20Mpa and a temperature of 45°C into the extraction kettle at a flow rate of 22.5L / min. 2 Extraction is carried out, and the CO saturated with dissolved substances after extraction 2 It is sent to the separator for separation, so that the extract can be separated from CO 2 Precipitate in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com