Desulfurizing absorbing separator

A separation device and separation tower technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large pressure loss, high operating cost, high moisture content, etc., and achieve stable matching dimensions, simplified The structure and the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

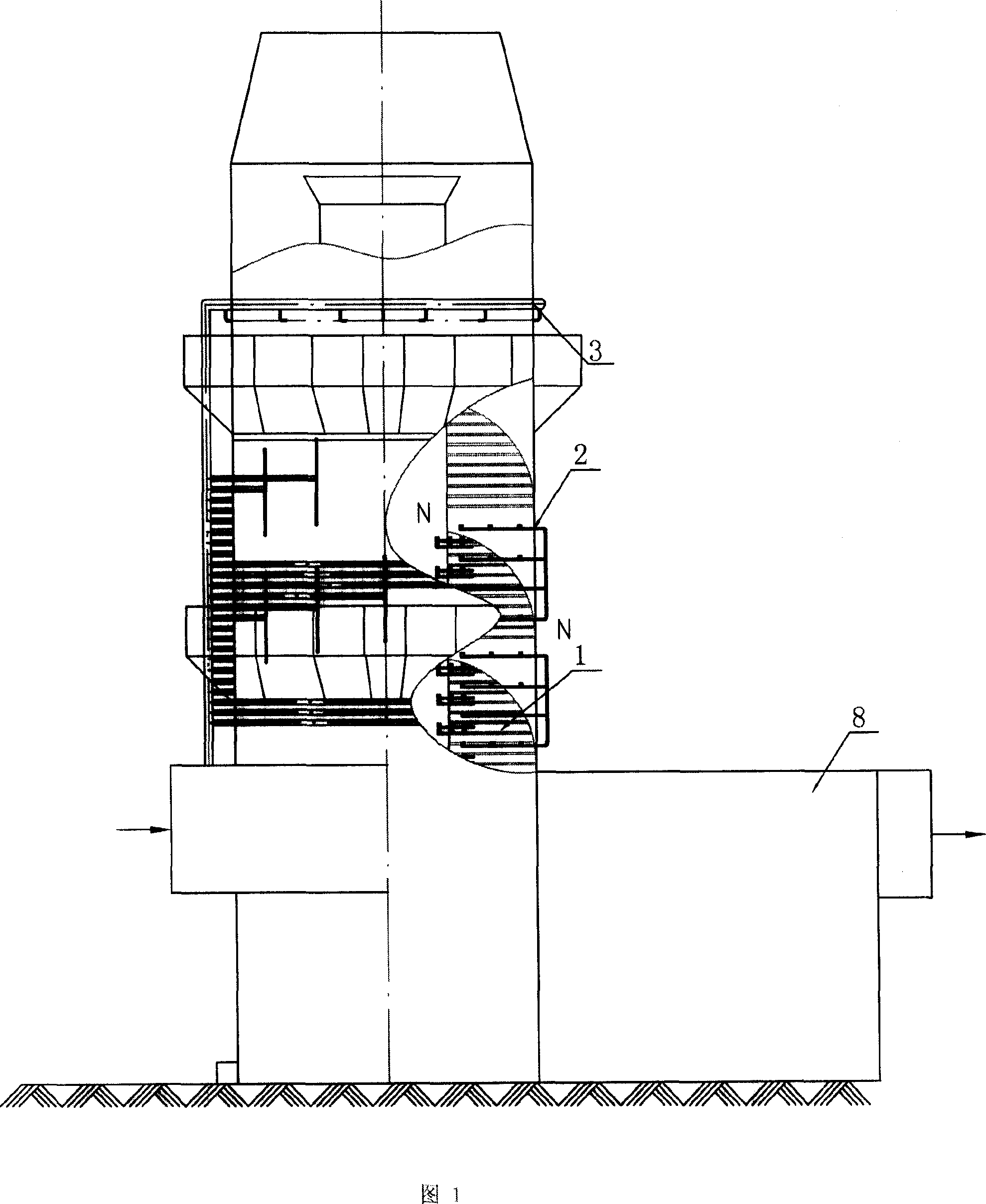

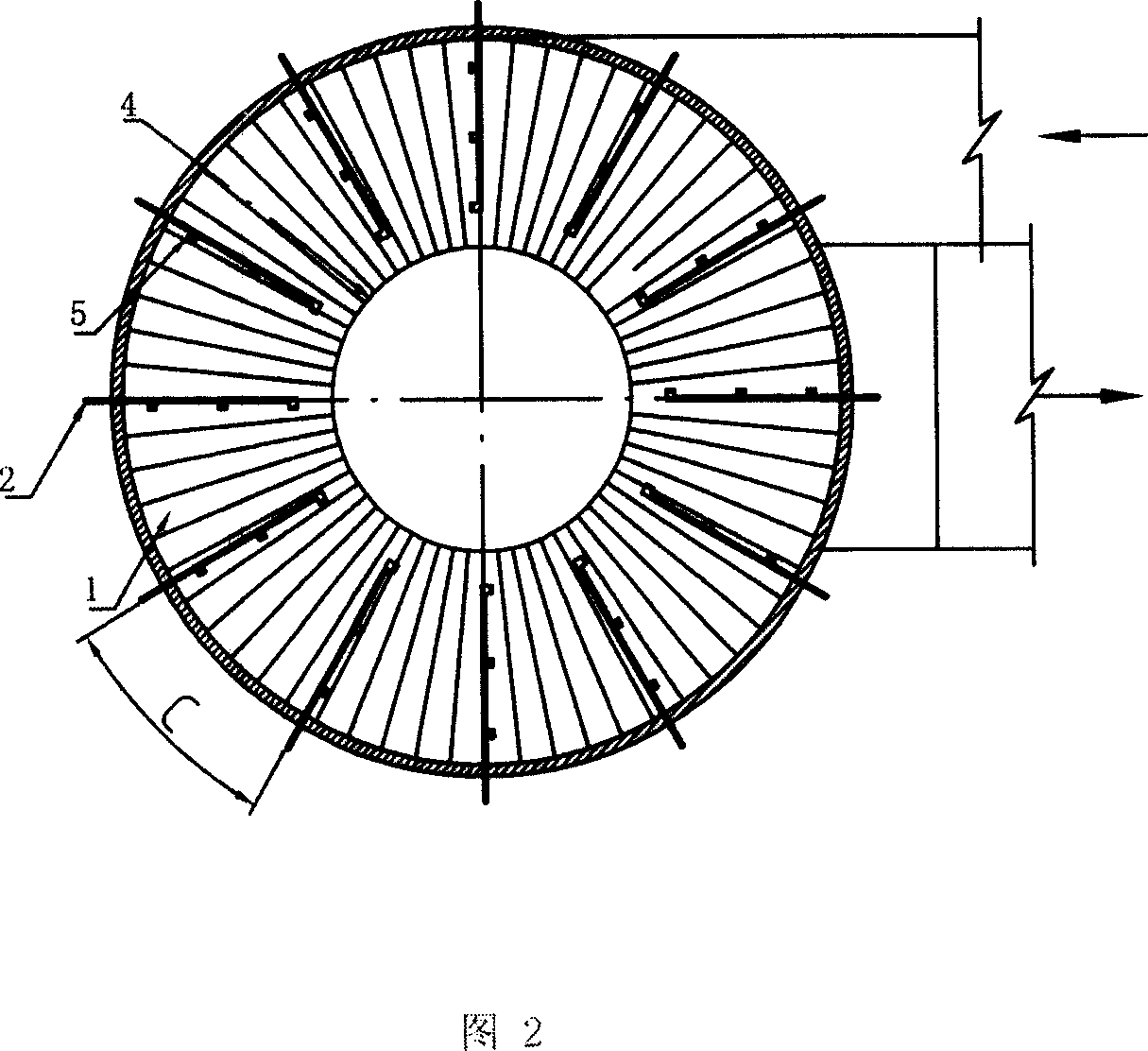

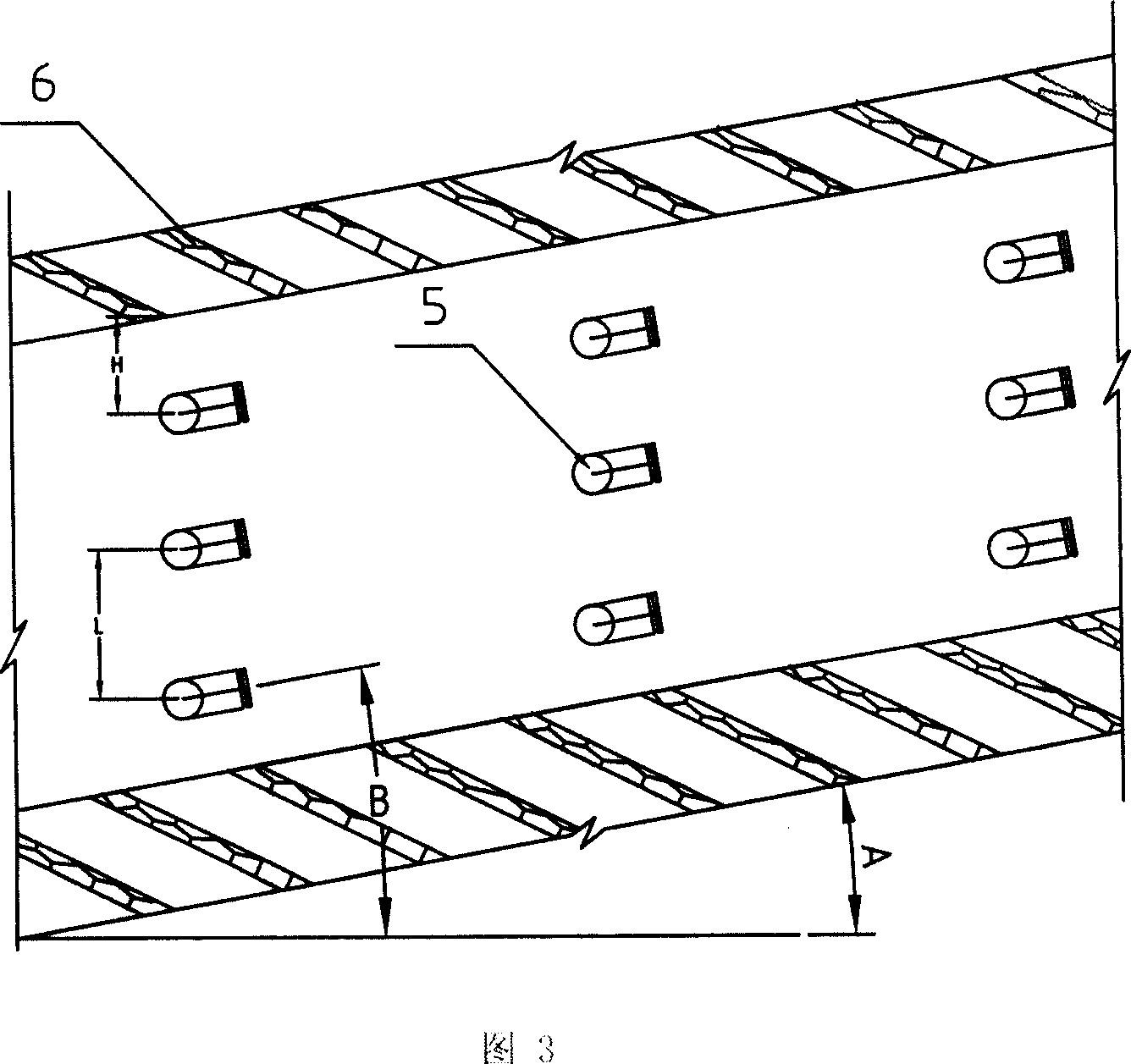

[0021] After the flue gas enters the desulfurization absorption and separation device, it contains SO 2 The flue gas enters the spiral passage formed by the swirl plate (6) between the outer cylinder and the centrifugal inner cylinder, and performs a spiral upward movement along the passage between the lower layer and the upper layer of the spiral swirl device (1). The spiral channel is divided into multiple sections, and a group of splash cone nozzles (5) are arranged on each section. Multiple sets of splash-cone nozzles form a spray system (2). The desulfurizer is sprayed out from the nozzle to form a liquid mist curtain. The splash cone nozzle (5) has a certain spray pressure, which can maximize the atomization of the sprayed absorption liquid, thereby reducing the droplet diameter, increasing the atomization coverage of this surface, increasing the mass transfer surface area, and prolonging the droplet diameter. Depending on the residence time of the flue gas in the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com