Assembly method and preparation technology of compound metformin hydrochloride and pioglitazone hydrochloride slow-release micro-pellet preparation

A technology of compound metformin hydrochloride pioglitazone hydrochloride and metformin hydrochloride, which is applied in the direction of pharmaceutical formulas, drug combinations, medical preparations containing active ingredients, etc., can solve the problem of imperfect preparation process and equipment of double-layer osmotic pump technology, and poor drug compliance of patients Ideal and other issues, to achieve the effect of small differences in individual bioavailability, reduce the number of medications, and improve the curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

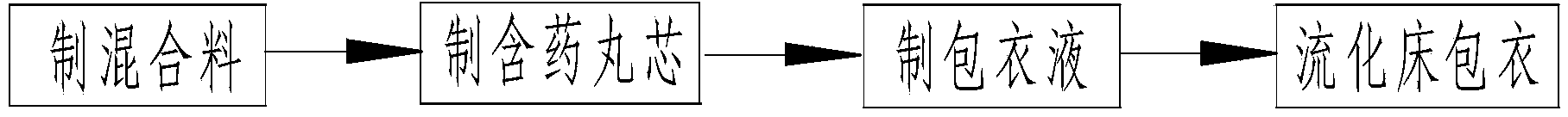

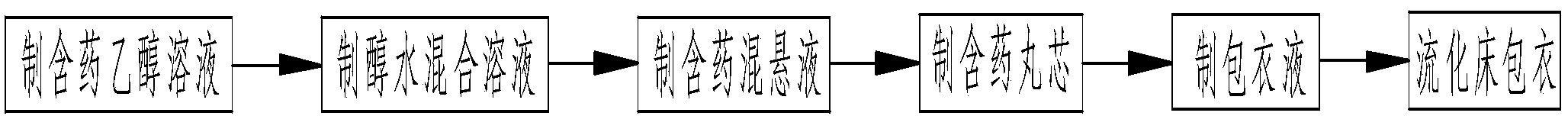

[0032] Metformin hydrochloride sustained-release pellets are composed of drug-containing pellet core and sustained-release layer. The drug-containing pellet core is composed of metformin hydrochloride, filler and binder, and the sustained-release layer is composed of sustained-release materials and porogens; pioglitazone hydrochloride sustained-release The micropill is composed of three parts: a blank pellet core, a drug-containing layer and a sustained-release layer. The drug-containing layer is composed of pioglitazone hydrochloride, a binder, and a solubilizer, and the sustained-release layer is composed of a sustained-release material and a pore-forming agent; the composition weight percentage For: metformin hydrochloride 20.0-35.0%, used for the filler of metformin hydrochloride sustained-release pellets 15.0-37.5%, used for the binder of metformin hydrochloride sustained-release pellets 0.2-2.5%, used for metformin hydrochloride sustained-release pellets 2.3-8.4% of susta...

Embodiment 2

[0034] The fillers purchased from the market are microcrystalline cellulose, lactose, sucrose, and starch "one or a combination of several"; the binders purchased from the market are hypromellose, povidone, and carboxymethyl cellulose cellulose, methyl cellulose, ethyl cellulose, polyethylene glycol, sucrose solution, sodium alginate, gelatin "one or a combination of several"; Alcohol fatty acid esters, sodium lauryl sulfate "one or a combination of several"; the slow-release materials purchased from the market are acrylic resin water dispersion Eudragit, ethyl cellulose water dispersion product Su Lisi, Cellulose acetate and lipid materials "one or a combination of several"; porogens purchased from the market are hypromellose, polyvinyl alcohol, sodium chloride, povidone, mannitol, lactose, ten Sodium dialkyl sulfate "one or a combination of several".

Embodiment 3

[0036] Mix metformin hydrochloride, fillers and binders evenly to make a soft material, prepare metformin hydrochloride drug-containing pellet cores by extrusion spheronization or centrifugal granulation, preheat the metformin hydrochloride drug-containing pellet cores, and place the slow-release layer The coating solution is sprayed onto metformin hydrochloride drug-containing pellet cores to prepare metformin hydrochloride sustained-release pellets; pioglitazone hydrochloride, solubilizer and binder are mixed evenly, and pioglitazone hydrochloride drug-containing pellet cores are prepared by applying medicine to blank pellet cores. Preheat the pioglitazone hydrochloride drug-containing pellet core, spray the sustained-release layer coating solution on the pioglitazone hydrochloride drug-containing pellet core to prepare pioglitazone hydrochloride sustained-release pellets; do drug release for metformin hydrochloride sustained-release pellets and pioglitazone hydrochloride sust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com