Non-stick pot and manufacturing method for same

A manufacturing method and technology of non-stick pans, applied to special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problems of low wear resistance and scratch resistance, and achieve improved wear resistance and scratch resistance, good toughness and The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

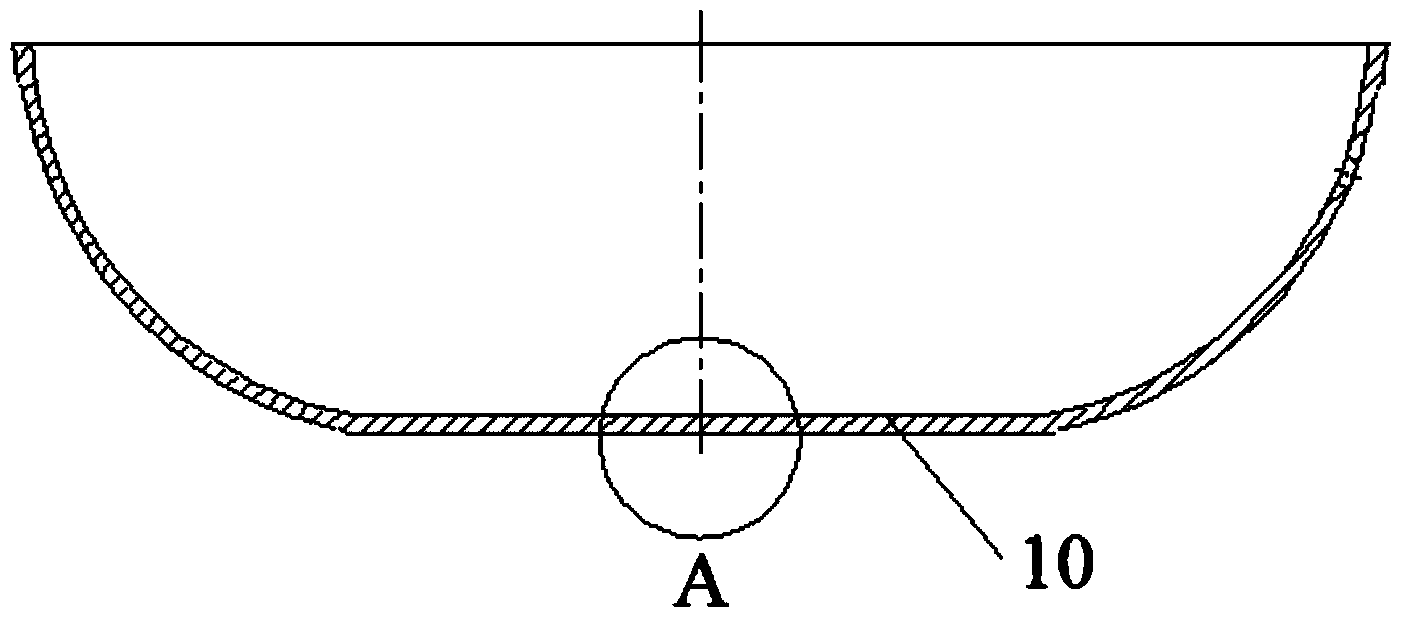

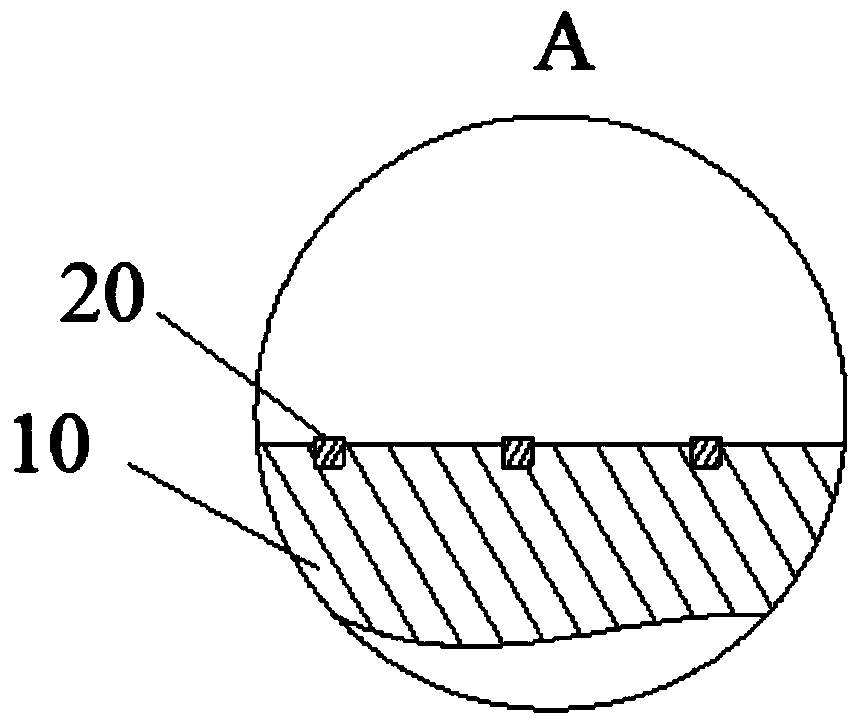

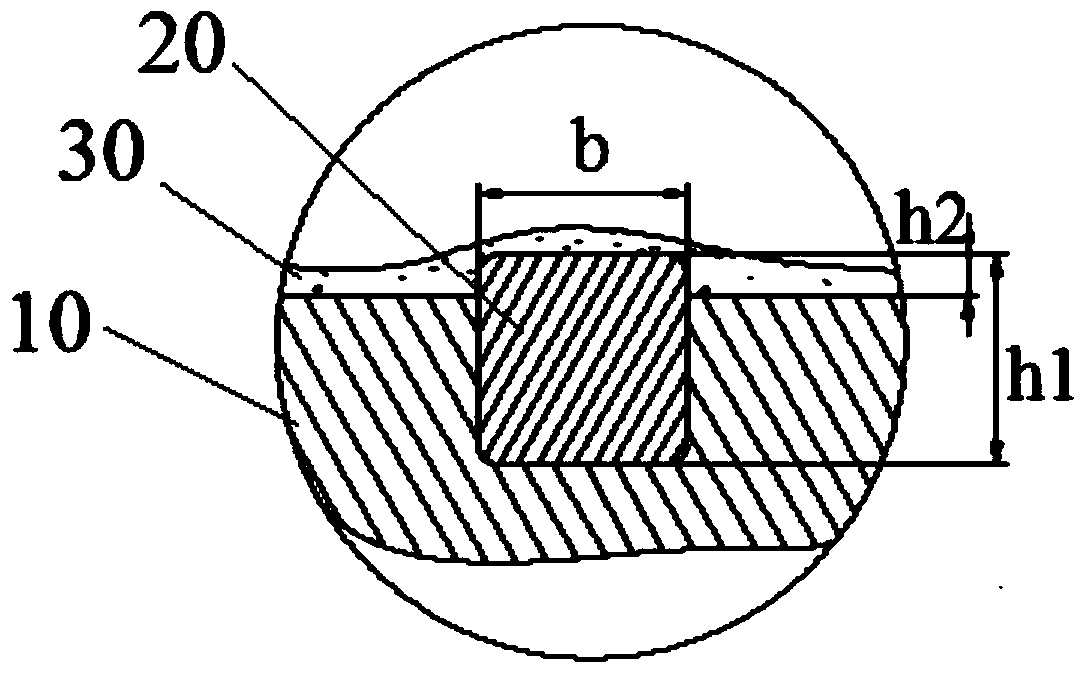

[0029] In the non-stick pan of the present invention, the main working parts of the inner surface of the pan are embedded or pressed into a mesh body made of titanium or other metals (such as stainless steel materials) that have been treated with surface hardening and corrosion resistance processes. Make the surface of the pot body form a textured structure, the ribs of the grid body form ridges for scratch resistance and wear resistance, the holes of the grid body are filled by the base material of the pot body, but the base material is slightly lower than the ribs of the grid body, the mesh holes Not fully filled, the non-stick coating can penetrate further into the mesh when sprayed.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com