Pure-cotton-gauze based sterile dustproof mask and producing method thereof

A dust-proof mask and pure cotton technology, applied in the field of sanitary protection products, can solve the problems of poor skin affinity, poor comfort, and inability to prevent bacteria from entering the respiratory tract, etc., and achieve mature processing technology, poor water absorption, and air permeability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

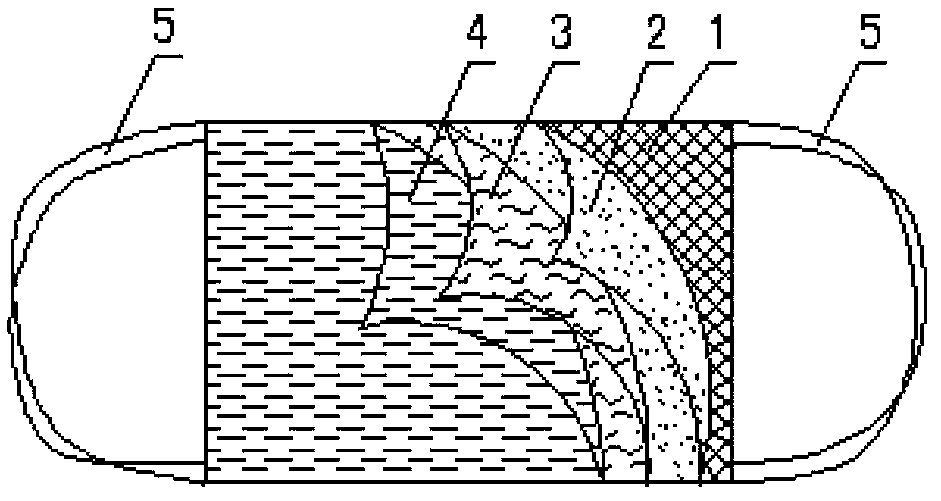

[0031] 1 gram weight of the pure cotton gauze of embodiment 1 is 40g / m 2 , PLA electrospun nanofiber membrane 2 has a grammage of 2.5g / m 2 , the mass percentage of ramie fiber in ramie needle-punched nonwoven fabric 3 is 100%, and the gram weight is 40g / m 2 , The mass percentage of PLA polyester in the PLA polyester meltblown cloth 4 is 100%, and the gram weight is 40g / m 2 .

[0032] The antibacterial and dustproof mask main body grammage based on pure cotton gauze of embodiment 1 is 122.5g / m 2 .

[0033] The preparation method of the PLA electrospinning nanofiber membrane 2 of embodiment 1 is as follows:

[0034] First prepare a uniform spinning solution with a PLA mass fraction of 8%, that is, dissolve 2002D PLA slices in a mixed solution of chloroform and acetone, the volume ratio of chloroform and acetone is 2:1, stir at room temperature for 2-3 hours, and the slices are fully dissolved Then let it stand until there are no bubbles.

[0035] The uniform spinning solut...

Embodiment 2

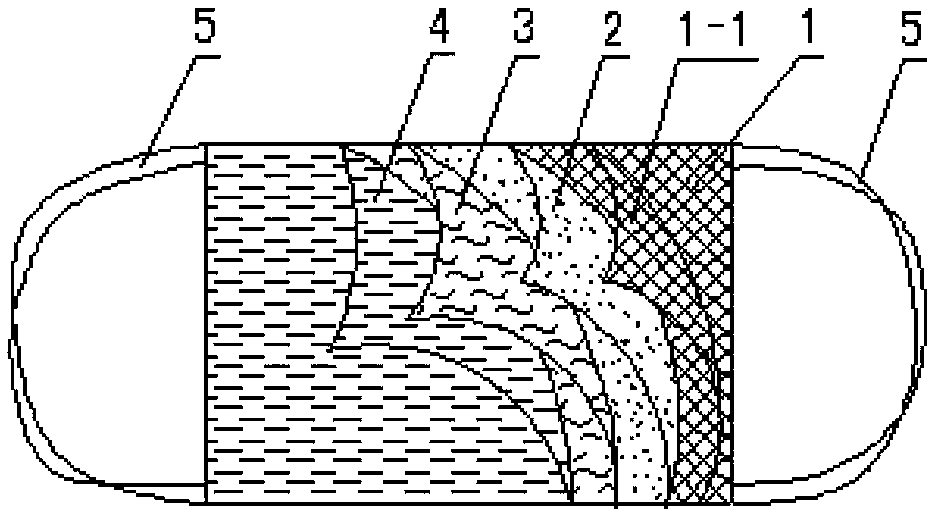

[0043] The grammage of the pure cotton gauze 1 of embodiment 2 and the 2nd layer pure cotton gauze 1-1 is 40g / m 2 , PLA electrospun nanofiber membrane 2 has a grammage of 2.5g / m 2 , the mass percentage of ramie fiber in ramie needle-punched nonwoven fabric 3 is 100%, and the gram weight is 80g / m 2 , The mass percentage of PLA polyester in the PLA polyester meltblown cloth 4 is 100%, and the gram weight is 40g / m 2 .

[0044] The antibacterial and dustproof mask main body gram weight based on pure cotton gauze of embodiment 2 is 202.5g / m 2 .

[0045] The preparation method of the PLA electrospun nanofiber membrane 2 of Example 2 is the same as that of Example 1.

[0046] The mass percentage composition of the ramie fiber of embodiment 2 is 100%, and the gram weight is 80g / m 2 The preparation method of the ramie needle-punched non-woven fabric is as follows:

[0047] The ramie fibers are finely opened, carded and laid on a carding machine to form a net, and the weight range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com