Capacitor touch screen manufacturing process

A technology of capacitive touch screen and manufacturing process, which is applied in the direction of electrical digital data processing, instrumentation, input/output process of data processing, etc., can solve the problem of affecting product appearance and service life, easily generating bubbles, and affecting the service life of touch screen and other issues, to achieve the effect of easy control of mass production yield, reduce the possibility of air bubbles, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

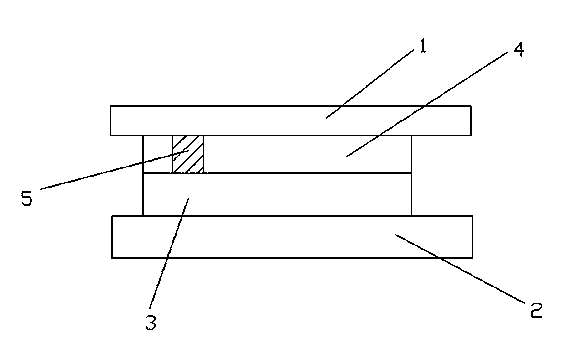

[0033] see figure 1 A capacitive touch screen includes: a display screen 2 at the bottom for displaying images; a cover 1 at the top for protecting an ITO FILM 3, and the ITO FILM 3 is located at the display screen 2 and the cover 1 In between, the cover plate 1 and the ITO FILM 3 are glued together through the OCA 4, and the OCA 4 is dug with a hole 5 for placing a button icon, and the size of the hole 5 is smaller than that of the button icon (not shown). The actual size of the peripheral extension is 40-50 microns, and the hole position 5 is a through hole.

Embodiment 2

[0035] A manufacturing process for a capacitive touch screen, the steps comprising:

[0036] S1, prepare ITO (Indium Tin Oxides, nano-indium tin metal oxide) FILM: cut the ITO FILM roll film according to the specification size to obtain ITO FILM, wherein the square resistance of the ITO FILM is 150±50Ω;

[0037] S2, printing protective glue: printing protective glue on the non-conductive surface of the ITO FILM, the thickness of the protective glue is 8-12um;

[0038] S3, aging treatment: put the ITO FILM into the oven for baking and aging;

[0039] S4, printing acid resistance: acid resistance is printed on the aged ITO FILM, and the deviation between the acid resistance and the film target during printing is ≤0.1mm;

[0040] S5, UV baking: put the ITO FILM into the oven for baking;

[0041] S6, acid-base etching: put the baked ITO FILM into an acid etching solution for acid etching, and then put the acid-etched ITO FILM into an alkaline etching solution for alkaline etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com