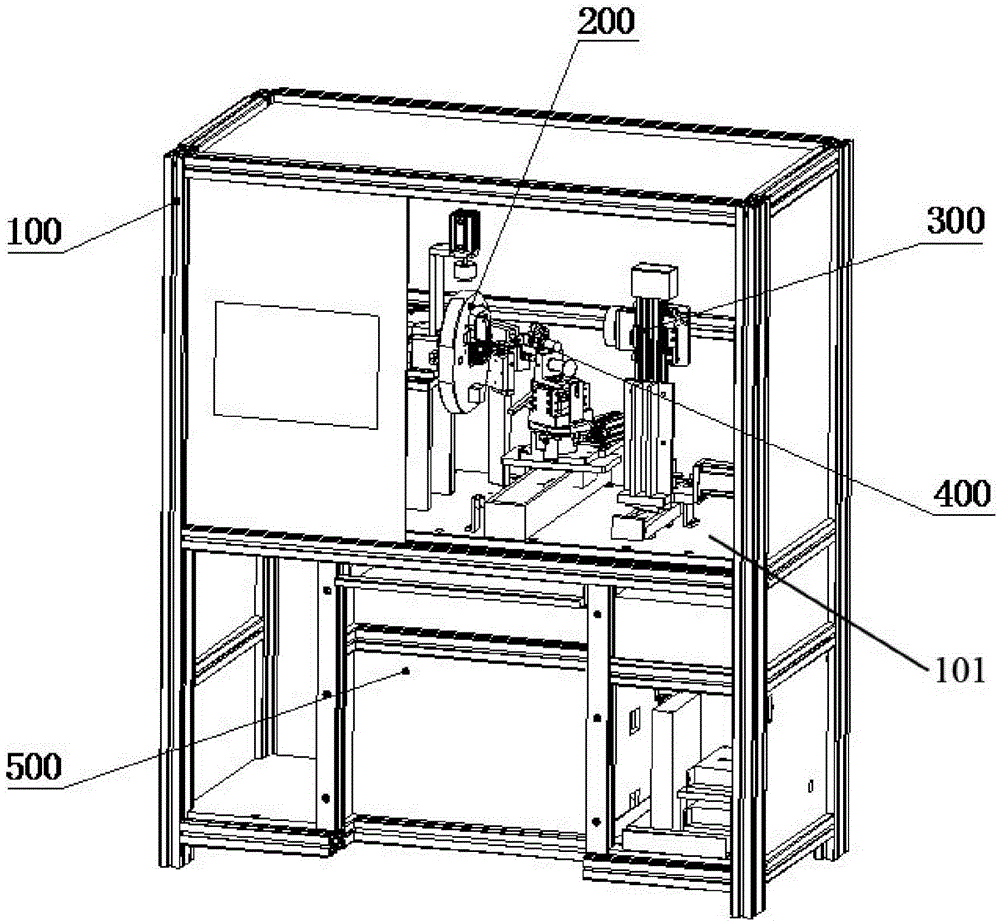

Precise automatic adjustment method and device of balance of instrument machine core

An automatic adjustment and movement technology, applied in the mechanical field, can solve the problems of cumbersome and complicated movement balance process, large error, poor controllability, etc., and achieve the effects of good consistency, high production efficiency and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

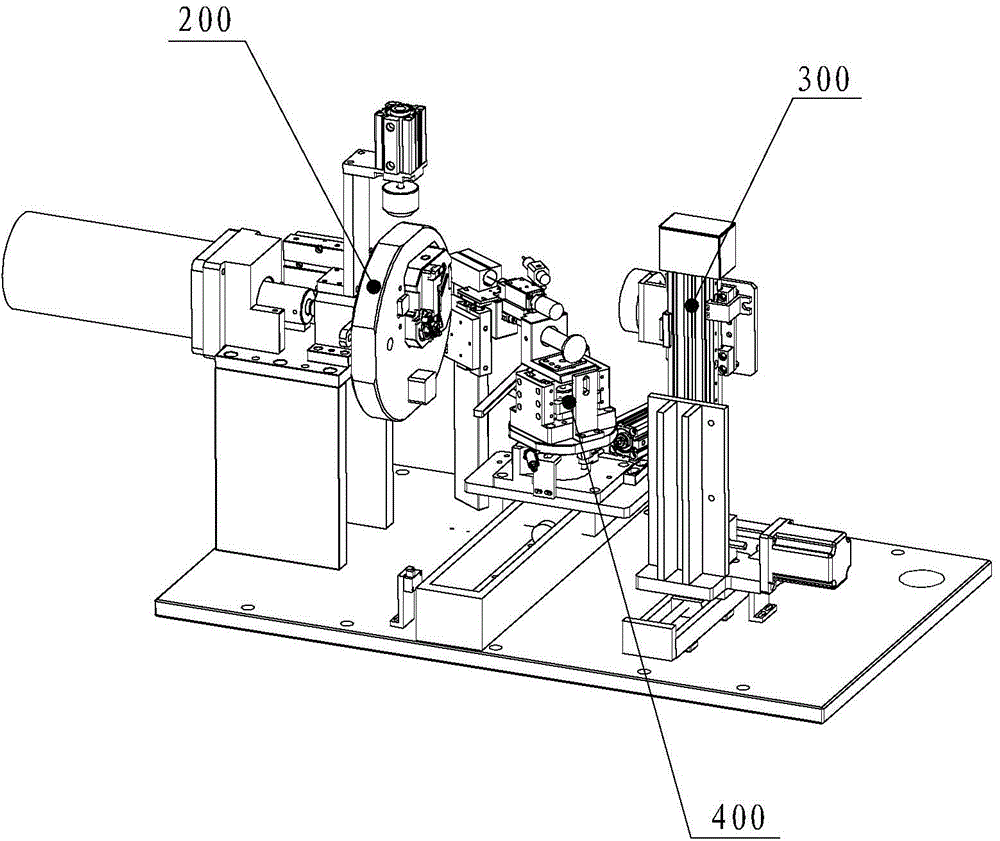

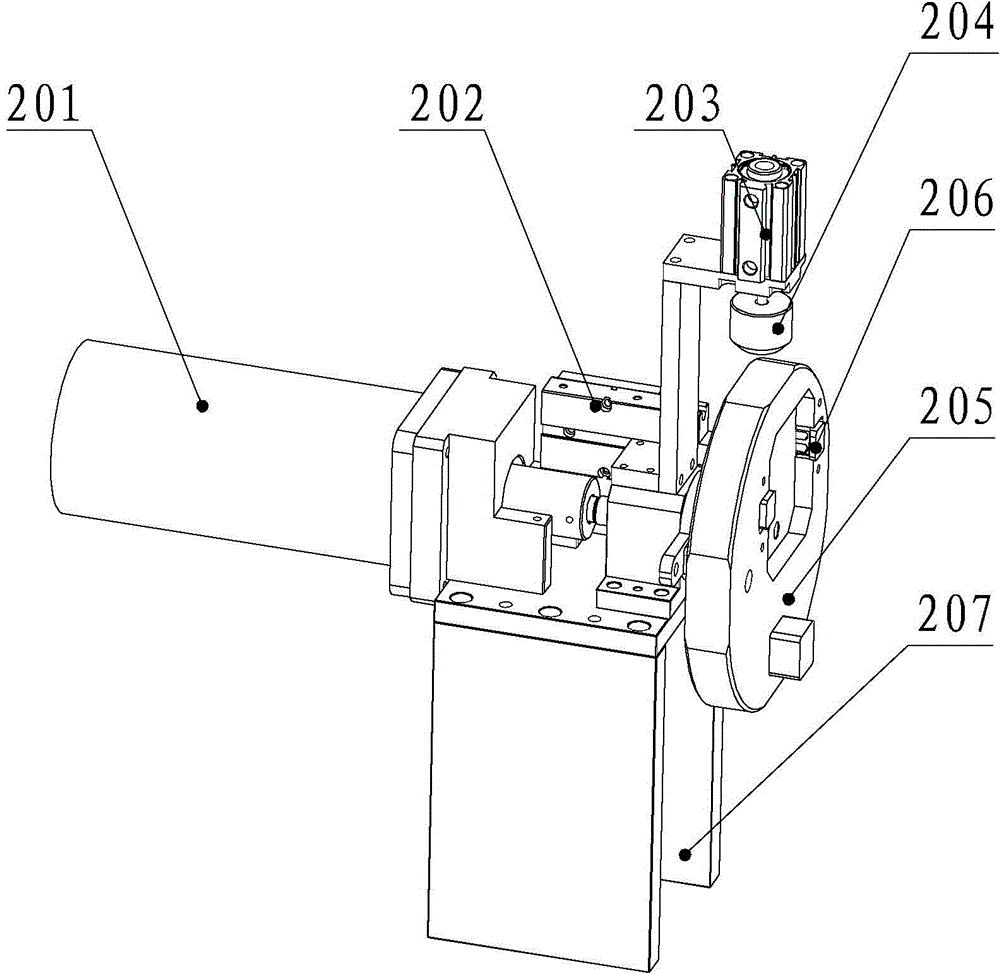

Embodiment 1

[0023] The precision automatic adjustment method for instrument movement balance of the present invention includes a step of adding counterweights to the movement, wherein, in the step of adding counterweights to the movement, a clamp is used to fix the to-be-adjusted The core uses a glue spraying controller to control a glue spraying valve to spray a suitable amount of glue onto the core, and utilizes a light source to irradiate and cure the glue on the core, and add glue to the core during implementation. Before the step of the counterweight, the movement to be adjusted is loaded into the fixture and fixed, and then an image sensor is used to measure the angle of the pointer in the movement relative to a given reference line, and the measurement result is sent to A computer, then rotate the movement 180 degrees in its pointer rotation plane, and then use the image sensor to measure the angle of the pointer relative to the reference line, and send the measurement result to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com