Test method for quickly evaluating corrosion of reinforcement bars in chloride ion environment

A test method and corrosion test technology, applied in the direction of weather resistance/light resistance/corrosion resistance, weighing and measuring devices by removing certain components, can solve problems that cannot be well applied to actual needs, and achieve acceleration and reproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

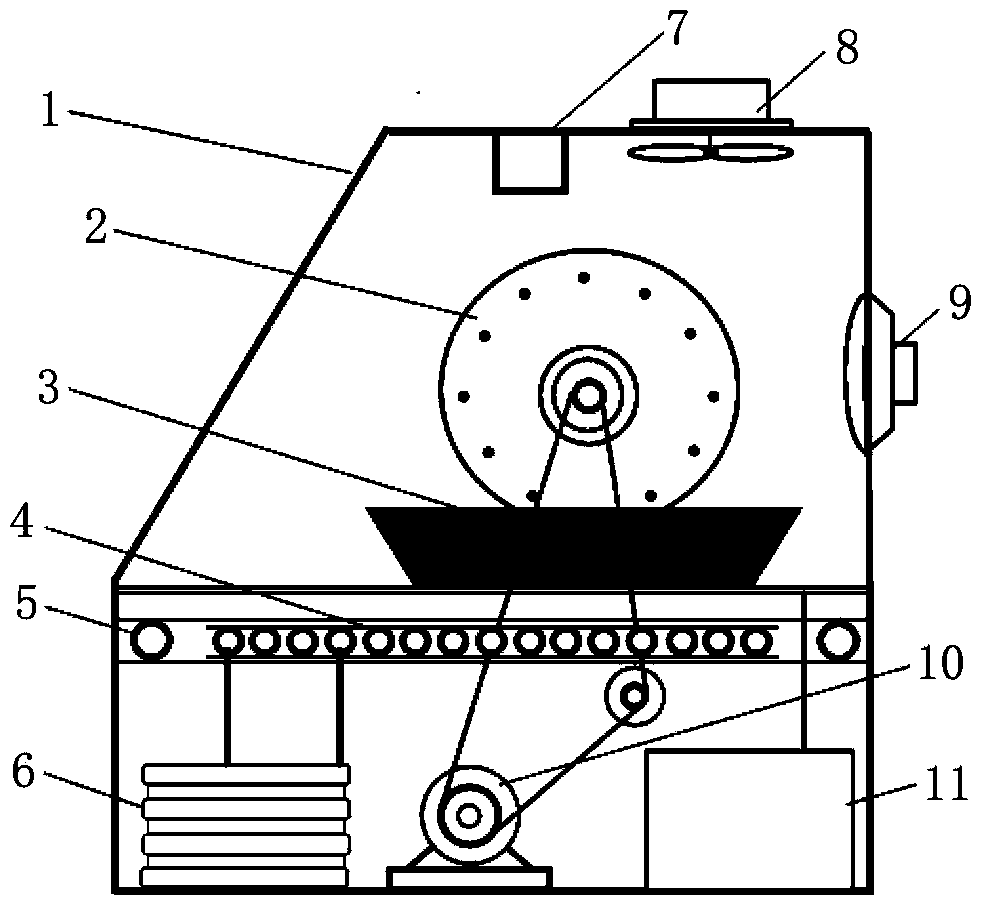

Image

Examples

Embodiment 1

[0056] The test materials are the 5 kinds of steel bars in the above test examples (ie, 0#~4# steel bar samples), which are processed according to the sample size diagram. Perform pretreatment according to the method described in the above test example, and prepare test samples. Sodium chloride solutions with test solution concentrations of 0.01%, 0.10%, 0.30%, 0.50%, 0.60%, 0.75%, 1.25%, 1.50%, 20%, 2.50%, and 3.50% were prepared respectively, and the pH value was 7.0. Set the temperature of the bath solution in the peripheral immersion testing machine to 45°C±2°C, keep the humidity in the box at 70%RH±10%RH, and conduct cycle experiments in the order of "immersion→wetting→drying", the cycle period is 60min ±5min, of which, the infiltration time is 12min±2min, and the test period is 72h.

[0057] image 3 It is a graph showing the average corrosion rate of 0# to 4# steel bars in different mass fractions of sodium chloride solution environment according to Example 1. Depend...

Embodiment 2

[0059] The test material is the above-mentioned 0# steel bar, processed according to the sample size drawing, and pre-treated according to the method described in the test example. Prepare test samples, and prepare sodium chloride solutions with initial pH values of 7.0, 10.2, 11.2, 11.37, 11.68, 11.80, 11.94, 12.04, and 12.46, with a mass fraction of 2.00%. Control the temperature of the bath solution in the weekly immersion testing machine at 45°C±2°C, keep the humidity in the box at 70%RH±10%RH, and conduct the cycle test in the order of "dipping→wetting→drying", the cycle period is 60min±5min, Among them, the infiltration time is 12min±2min, and the test period is 72h. The effect of steel corrosion on solution pH was regularly monitored for the initial pH values of 11.94 and 12.46, respectively.

[0060] Figure 4 It shows the average corrosion rate of the 0# comparison steel bar of embodiment 2 in the sodium chloride solution environment of different pH values. Dep...

Embodiment 3

[0063]The test materials are the 5 kinds of steel bars in the above test example (ie, 0#~4# steel bar samples). According to the test result of embodiment 1 and embodiment 2, find suitable, stable accelerated test condition: sodium chloride solution mass fraction is 2.00%, and initial solution pH value is 6.5~7.5, and the solution temperature in the immersion testing machine is 45 ℃±2℃, the humidity in the box is 70%RH±10%RH, the cycle period is 60min±5min, in which the soaking time is 12min±2min, and the test period is 72h. Carry out repeated test to embodiment 1, and test result analysis, analysis acceleration and reproducibility.

[0064] The test results are shown in Tables 2 and 3 below and Image 6 with Figure 7 , where Table 2 and Image 6 The average corrosion rate of the five steel bars in Example 3 in a sodium chloride solution environment with a mass fraction of 2.00% is shown. Table 3 and Figure 7 The average corrosion depth of the five steel bars in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com