Oil pipeline leakage detection and positioning system

A leak detection and positioning system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of low accuracy, difficult detection, high cost, reduce accumulated clock errors, save wired resources, and locate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

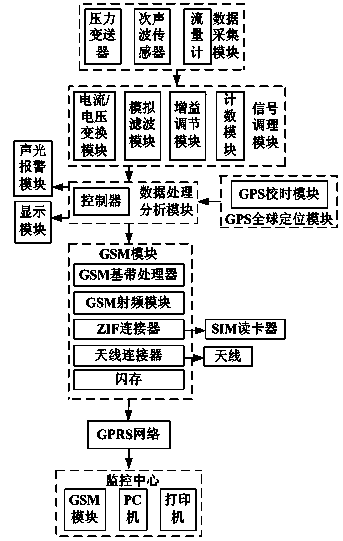

[0018] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0019] An oil pipeline leakage detection and positioning system, its main technical features are: including data acquisition module, signal conditioning module, data processing and analysis module, sound and light alarm module, display module, GPS global positioning module, GSM module, GPRS network and monitoring center, the data acquisition module includes a pressure transmitter, an infrasonic sensor and a flow meter, the signal conditioning module includes a current / voltage conversion module, a counting module, and an analog filter module, and the data processing and analysis module includes a controller, the The data acquisition module is connected to the signal conditioning module, the signal conditioning module is connected to the data processing and analysis module, the sound and light alarm module, the display module, the GPS global positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com