A method for purifying flue gas from a gas-fired internal combustion engine

A gas-fired internal combustion engine and flue gas purification technology, applied in the direction of internal combustion piston engine, combustion engine, exhaust gas treatment, etc., can solve the problems of unfavorable reduction reaction denitration process, high nitrogen oxide concentration, high nitrogen oxide emission concentration, etc. Denitration efficiency and effective use of ammonia, reduction of denitration costs, and effects of low ammonia leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

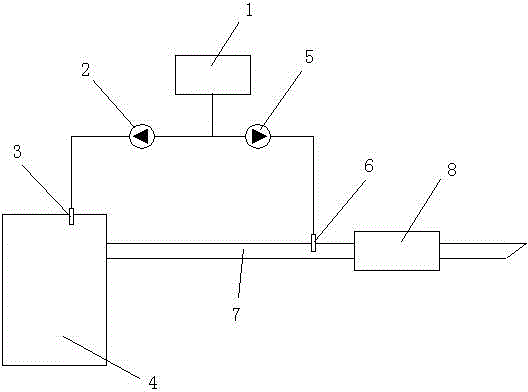

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] The present invention includes cylinder head denitrification and flue denitrification, and the system structure schematic diagram that it adopts is as attached figure 1 As shown, the cylinder head denitrification is to pressurize the ammonia gas in the ammonia tank 1 to a pressure of more than 10 kg through the cylinder head injection pump 2 to enter the cylinder head injector 3, and the cylinder head injector 3 controls its opening and closing by a signal, and the Ammonia is injected into the exhaust branch pipe near the combustion chamber of the engine 4 or the exhaust valve. The flue denitrification is to pressurize the ammonia gas in the ammonia tank 1 to a pressure of more than 10 kg through the flue injection pump 5 and enter the flue injector 6, and the flue injector 6 then injects the ammonia gas into the exhaust pipe 7 of the engine middle. The cylinder he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com