Alkaline biological enzyme deinking agent and application technology thereof in waste paper deinking

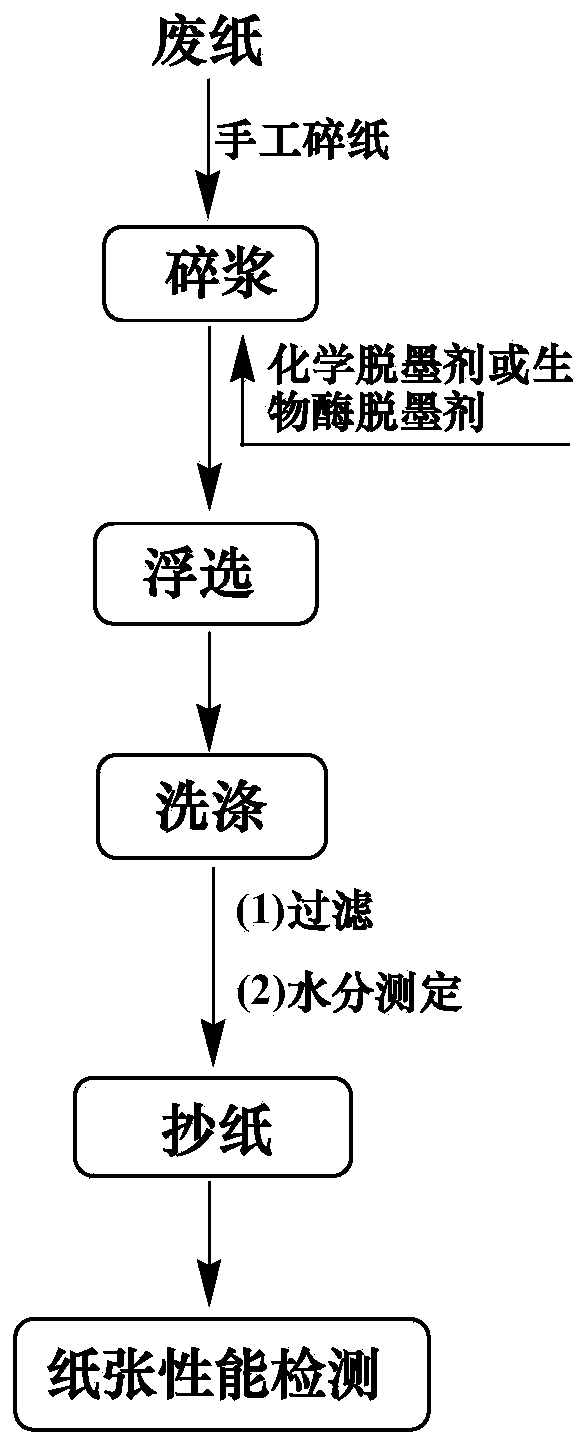

A waste paper deinking and biological enzyme technology, which is applied in the processing of waste paper, papermaking, paper recycling, etc., can solve the problems of poor catalytic deinking effect, etc., and achieve the effect of good deinking effect, simplified process and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Application of a biological enzyme deinking agent in the deinking of old newspapers (the effect of pulp concentration on deinking): 120g of old newspapers (best-dry pulp) that were manually shredded into 20mm×20mm and 1.0U / g of dry-dry pulp ARL lipase and 0.25% absolute dry pulp (w / w) Tween-80 were evenly mixed, the pulp concentrations were 8%, 10%, 12%, 15% and 18%, respectively, at 50°C (the optimal temperature for ARL ) under the condition of pulping for 25 minutes; then flotation in a 12L flotation tank with a slurry concentration of 1% and a temperature of 60-65°C for 7 minutes, and then washed with a punching screen for 2 minutes to 3 minutes. Each group of experiments was repeated 3 to 5 times. The experimental results show that when the pulp concentration is 10%, the whiteness of the deinked pulp is the highest, and the residual ink value is the lowest. Replace ARL with S7, repeat all the above experiments, the conclusion is the same.

Embodiment 2

[0038] Application of a biological enzyme deinking agent in the deinking of old newspapers (the effect of the amount of enzyme added on deinking): 120g of old newspapers (dry pulp) that were manually shredded into 20mm×20mm, with a pulp concentration of 10%, Mix evenly with ARL lipase and 0.25% Tween-80 of dry pulp (w / w), the addition amount of ARL lipase is 0.5, 1.0, 1.5, 2.0, 2.5 and 3.0U / g dry pulp, at 50 ℃ (the optimum temperature of ARL) for pulping for 25 minutes; then flotation in a 12L flotation tank with a slurry concentration of 1% and a temperature of 60-65℃ for 7 minutes, and then washed with a punching screen for 2 minutes to 3 minutes. Each group of experiments was repeated 3 to 5 times. The experimental results show that when the ARL addition amount is 1.0U / g absolute dry pulp, the whiteness of the deinked pulp is the highest, and the residual ink value is the lowest; When the pulp is dried, there is little difference in the whiteness and residual ink value of ...

Embodiment 3

[0040] Application of a biological enzyme deinking agent in the deinking of old newspapers (the impact of pulping time on the deinking effect): 120g of old newspapers (best dry pulp) hand-crushed into 20mm×20mm, with a pulp concentration of 10%, Mix evenly with 1.0U / g ARL lipase of dry pulp and 0.25% Tween-80 of dry pulp (w / w), and pulp at 50°C (the optimum temperature of ARL), and the time is 15 , 20, 25, 30, 35, 40, 50 and 60 minutes; then flotation in a 12L flotation tank with a slurry concentration of 1% and a temperature of 60-65°C for 7 minutes, and then washed with a punching screen for 2 minutes to 3 minutes. Each group of experiments was repeated 3 to 5 times. The experimental results show that it takes 20-30 minutes for the raw material - old newspapers to be crushed into pulp under the action of deinking agent and mechanical force. With the prolongation of time, the whiteness of the deinked pulp decreases and the residual ink value increases. Replace ARL with S7, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com