Self-lubricating coating tool prepared based on electric discharge deposition and its preparation method

A technology of EDM deposition and self-lubricating coating, applied in coating and metal material coating process, etc., can solve the problems of coating damage, fall off, cannot be repaired, peeling, etc., so as to reduce tool wear and improve friction and lubrication state. , the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A self-lubricating coating tool prepared based on electric spark deposition and a preparation method thereof. The base material of the tool is YT15 hard alloy, and the electrodes are bundled with copper microtubes. Concrete preparation steps are as follows:

[0023] (1) Preparation of electrodes

[0024] Six copper tubes with a diameter of 1 mm were filled with BN powder, and the average diameter of the particles was 2 microns. Then 6 copper tubes are tightly bundled together with fine copper wires, and the whole bundled copper tubes are used as electrodes.

[0025] (2) Deposition of self-lubricating coating on the surface of the blade

[0026] (1) Grind the base material of the tool with 80# sandpaper first to remove the oxide film on the surface of the substrate, then use 600# sandpaper to polish, then use acetone to perform ultrasonic cleaning for 15 minutes to remove surface oil, and then put it in a vacuum drying oven to dry After that, spare.

[0027] (2) Inst...

Embodiment 2

[0030] A self-lubricating coating tool prepared based on electric spark deposition and a preparation method thereof. The base material of the tool is W6Mo5Cr4V2 high-speed steel, copper is used to prepare a cylindrical electrode, and the end surface is processed with micro-holes. Concrete preparation steps are as follows:

[0031] (1) Preparation of electrodes

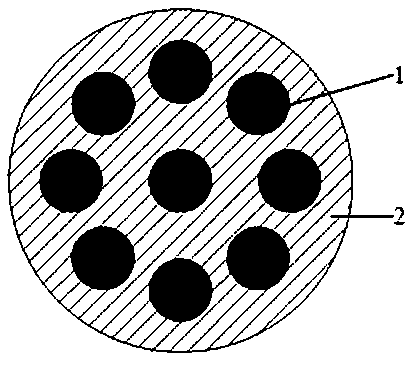

[0032] Pure copper is prepared as an electrode with a diameter of 6mm, and microholes are drilled on the end face, with a diameter of 1mm and a depth of 5mm, and MoS is filled in it 2 Solid lubricant, the average particle diameter is 2um. The microwells are arranged as shown in the figure.

[0033] 2) Deposition of self-lubricating coating on the surface of the blade

[0034] (1) Grind the base material of the tool with 80# sandpaper first to remove the oxide film on the surface of the substrate, then use 600# sandpaper to polish, then use acetone to perform ultrasonic cleaning for 15 minutes to remove surface oil, ...

Embodiment 3

[0038] A self-lubricating coating tool prepared based on electric spark deposition and a preparation method thereof. The base material of the tool is YT15 hard alloy, and the electrodes are bundled with nickel microtubes. Concrete preparation steps are as follows:

[0039] (1) Preparation of electrodes

[0040] Five nickel tubes with a diameter of 2 mm were filled with BN powder, and the average diameter of the particles was 2 microns. Then 5 nickel tubes are tightly bundled together with thin copper wires, and the whole bundled nickel tubes are used as electrodes.

[0041] (2) Deposition of self-lubricating coating on the surface of the blade

[0042] (1) Grind the base material of the tool with 80# sandpaper first to remove the oxide film on the surface of the substrate, then use 600# sandpaper to polish, then use acetone to perform ultrasonic cleaning for 15 minutes to remove surface oil, and then put it in a vacuum drying oven to dry After that, spare.

[0043] (2) Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com