Special molybdenum powder used for automatic forming and preparation method thereof

An automatic forming, molybdenum powder technology, applied in the field of special molybdenum powder, can solve the problems of reduced sintering power, no fluidity, low production efficiency, etc., and achieves the effect of appropriate particle size distribution, high bulk density and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

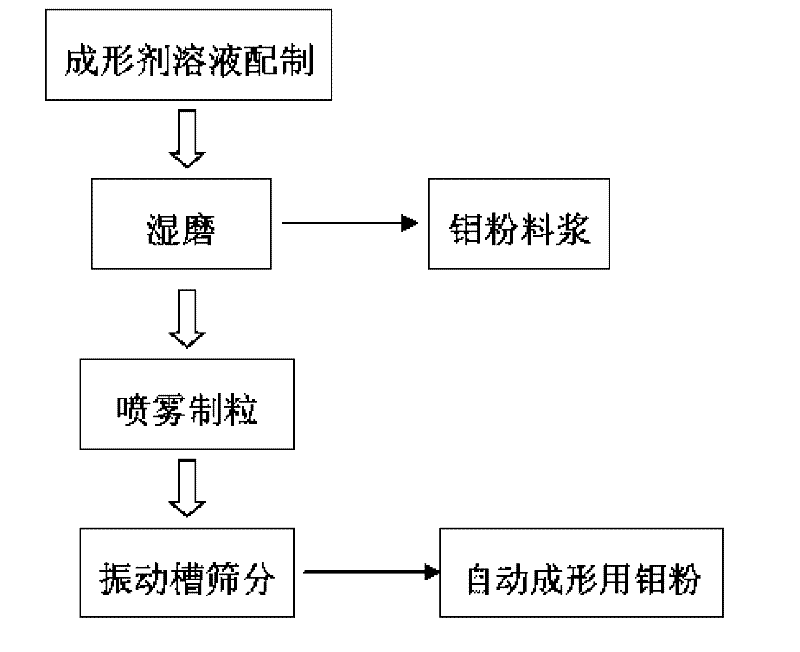

Method used

Image

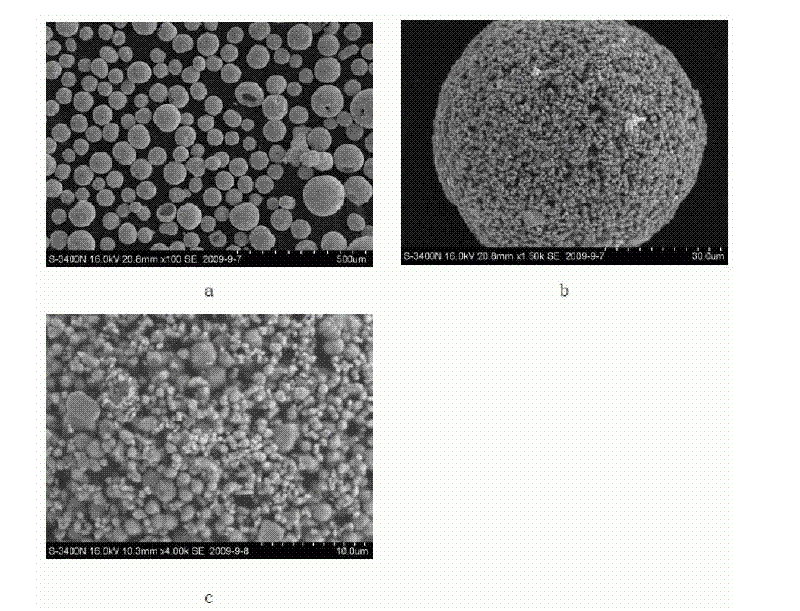

Examples

Embodiment 1

[0033] 200 parts of pure water, 5 parts of polyvinyl alcohol, and 1 part of polyethylene glycol were stirred at 80-90° C. for 2 hours to prepare a forming agent solution. According to the requirements of MP-1 in the Q / JDC013-2002 standard, take 1000 parts of raw molybdenum powder, and mix the 1000 parts of raw molybdenum powder, 3000 parts of hard alloy balls, and the prepared forming agent equivalent to 20.6% of the weight of the raw material molybdenum powder Put 206 parts of the solution into a roller mill for wet grinding and mixing for 18 hours to prepare a molybdenum powder slurry. Turn on the induced draft fan, blower fan and heating system of the spray drying tower in sequence, and use pure water for pre-spraying. Set the air inlet temperature of the spray drying tower to 260°C and the air outlet temperature to 130°C, and set it up for later use. The molybdenum powder slurry is pumped into the spray drying tower through a diaphragm pump and a spray gun for drying and ...

Embodiment 2

[0035] 300 parts of pure water, 13 parts of polyvinyl alcohol, and 2 parts of polyethylene glycol were stirred at 80-90° C. for 2 hours to prepare a forming agent solution. Take 1000 parts of raw material molybdenum powder according to the requirements of MP-1 in the Q / JDC013-2002 standard, combine these 1000 parts of raw material molybdenum powder, 3000 parts of stainless steel balls, and the forming agent solution 315% of the prepared material equivalent to 31.5% of the weight of the raw material molybdenum powder One part was put into a roller ball mill for wet grinding and mixed for 36 hours to prepare molybdenum powder slurry. Turn on the induced draft fan, blower fan and heating system of the spray drying tower in sequence, and use pure water for pre-spraying. Set the air inlet temperature of the spray drying tower to 265°C, and the air outlet temperature to 130°C, and set it up for later use. The molybdenum powder slurry is pumped into the spray drying tower through a ...

Embodiment 3

[0037] 500 parts of pure water, 25 parts of polyvinyl alcohol, and 4 parts of polyethylene glycol were stirred at 80-90° C. for 2 hours to prepare a forming agent solution. Take 1000 parts of raw material molybdenum powder according to the MP-1 requirement in the Q / JDC013-2002 standard, combine these 1000 parts of raw material molybdenum powder, 2000 parts of molybdenum balls, and the forming agent solution 529 of the prepared 52.9% of the weight of the raw material molybdenum powder One part was put into a roller mill for wet grinding and mixed for 10 hours to prepare molybdenum powder slurry. Turn on the induced draft fan, blower fan and heating system of the spray drying tower in sequence, and use pure water for pre-spraying. Set the air inlet temperature of the spray drying tower to 200°C and the air outlet temperature to 100°C, and set it up for later use. The molybdenum powder slurry is pumped into the centrifugal atomizing disc at the top of the spray drying tower thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com