Press forming machine and method

A technology of forming machine and stamping mechanism, applied in the field of stamping and forming machine, can solve the problems of affecting the effective utilization rate of the sheet, excessive sheet material, and increasing the stamping cost, so as to improve the effective utilization rate, reduce the cost, and improve the stamping efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

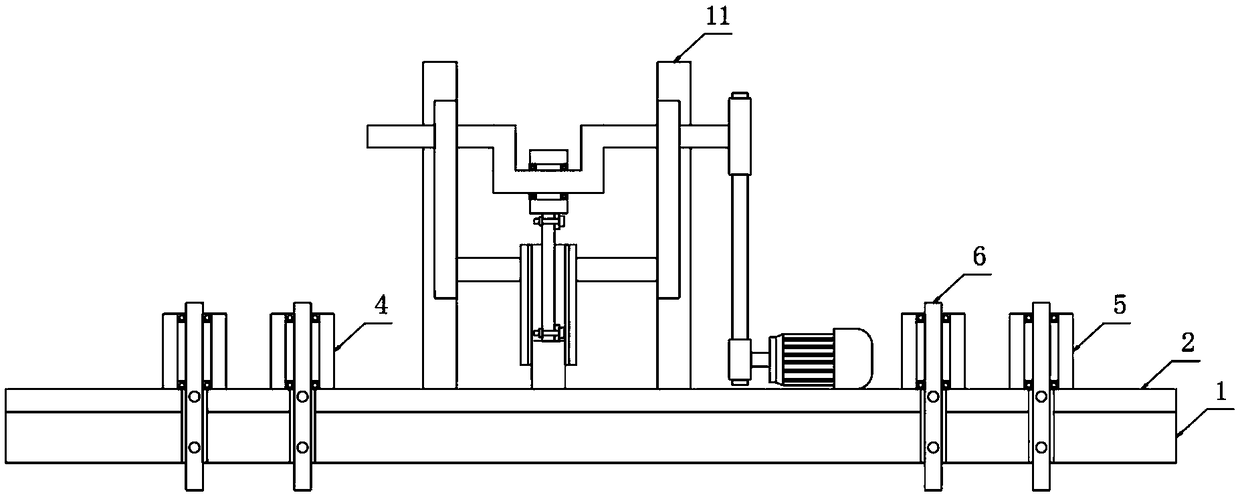

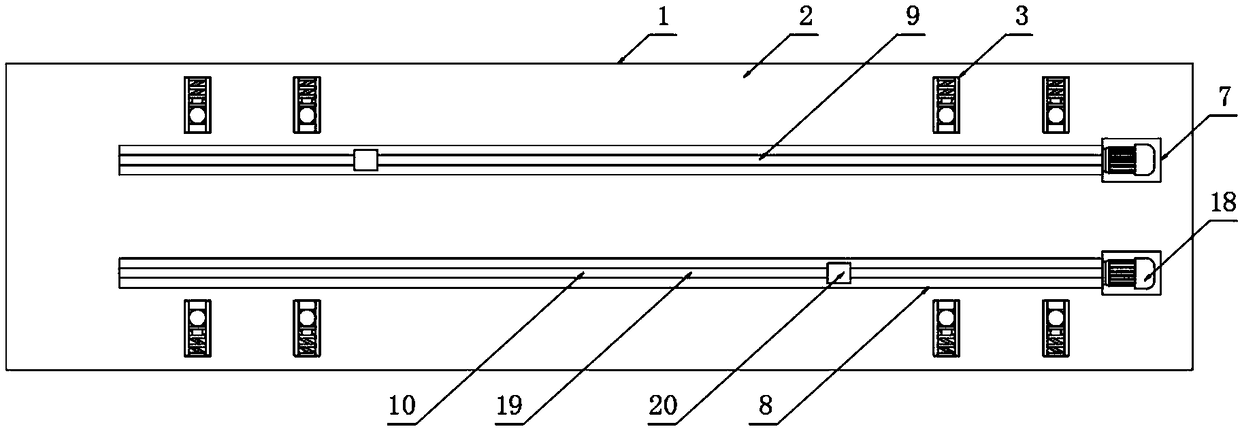

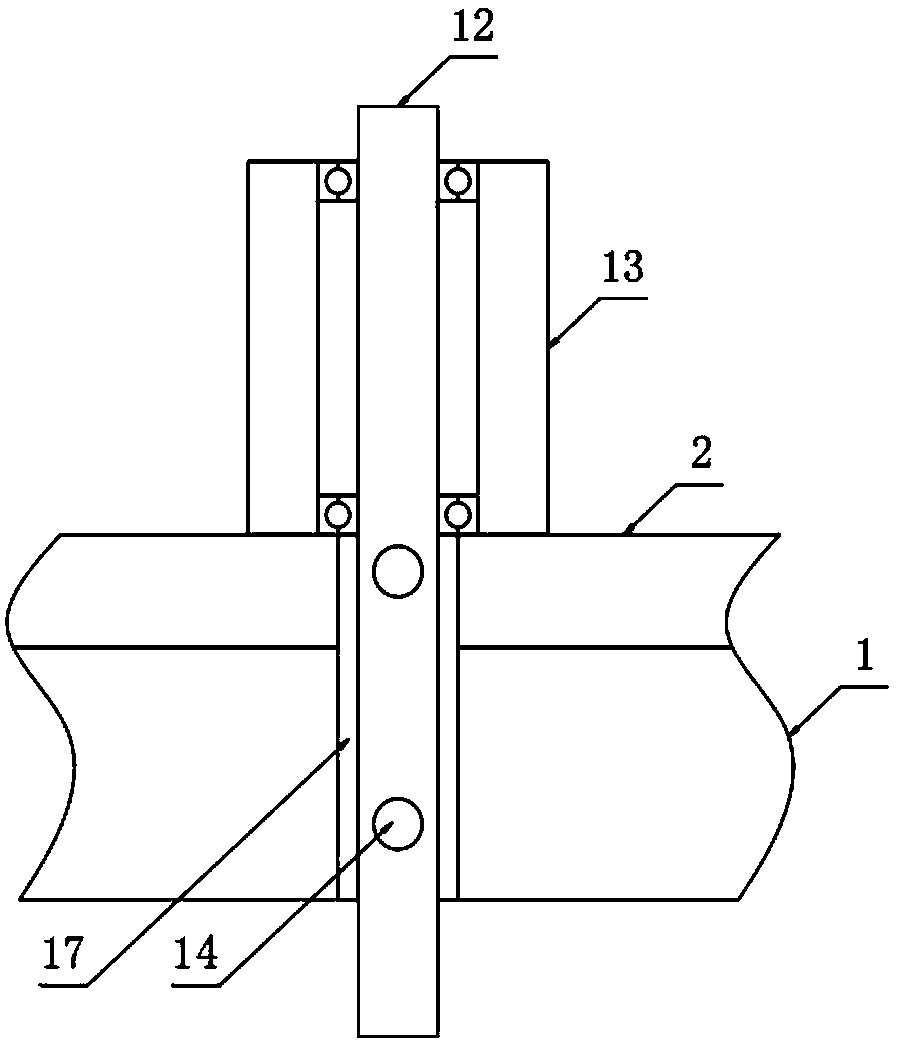

[0026] The present invention provides such Figure 1-5 The stamping machine shown includes a bed board 1, the top of the bed board 1 is bonded with an elastic pad 2, the top of the bed board 1 is provided with a longitudinal installation groove 3, and the inside of the longitudinal installation groove 3 is provided with a first limit Mechanism group 4 and the second limit mechanism group 5, the second limit mechanism group 5 is located on the first limit mechanism group 4 side, the first limit mechanism group 4 and the second limit mechanism group 5 Both include a limit mechanism 6, the top of the bed board 1 is provided with a first transverse installation groove 7 and a second transverse installation groove 8, the second transverse installation groove 8 is arranged on the side of the first transverse installation groove 7, and the second transverse installation groove 8 is arranged on the side of the first transverse installation groove 7. A first traveling mechanism 9 is ar...

Embodiment 2

[0037] A stamping forming method, including the stamping forming machine, also includes the following steps:

[0038] S1: Place the board on the top of the elastic pad 2, the elastic pad 2 effectively separates the bed board 1 from the board, at this time the edge of the board is in contact with the limit wheel 13, and the bottom of the board is in contact with the rubber suction head 22;

[0039] S2: Then start the vacuum pump, and the vacuum pump makes the rubber suction head 22 adsorb the plate through the hose and the exhaust pipe 23;

[0040] S3: Then start the motor 18 in the first traveling mechanism 9. When the motor 18 is reversing, it will drive the slider 20 to move left and right through the screw 19, so that the rubber suction head 22 drives the plate to move left or right, and then start the stamping Mechanism 11, the stamping mechanism 11 stamps the plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com