A kind of preparation method of weather-resistant pearlescent fluororesin coating

A fluororesin and pearlescent technology, applied in the field of coatings, can solve problems such as insufficient gloss and no antibacterial function, and achieve strong photocatalysis, strong adhesion, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

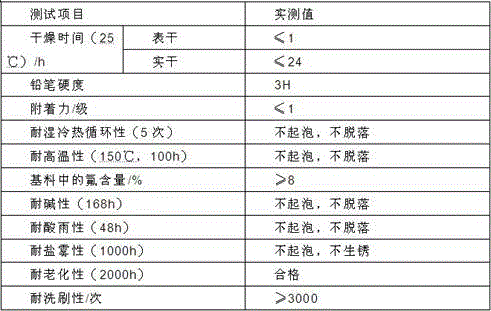

Image

Examples

Embodiment 1

[0021] A preparation method of a weather-resistant pearlescent fluororesin coating, comprising the steps of:

[0022] Step (1): Dissolving chlorotrifluoroethylene, cyclohexyl acrylate and ethylene trimethoxysilane in a mass ratio of 1:1:0.1 in n-butyl acetate to form a fluoropolymer with a solid content of 50% ;

[0023] Step (2): Weigh 100 parts of fluoropolymer obtained in step (1), 10 parts of isobutyl methacrylate, 6 parts of methyl methacrylate and 5 parts of isobornyl methacrylate, 12 parts of cyclohexyl methacrylate and 4 parts of γ-methacryloxypropyltrimethoxysilane were dissolved in xylene, and stirred at 65°C for 8 hours under the catalysis of azobisisobutyronitrile to obtain fluorine resin;

[0024] Step (3): 100 parts of fluororesin obtained in step (2) in parts by weight, 15 parts of mixed solvent, 0.3 part of dispersant 983 and 0.2 part of 8900-20X anti-settling agent are stirred and dispersed at high speed until mixed Evenly, the stirring speed is 1200~1600 r...

Embodiment 2

[0026] A preparation method of a weather-resistant pearlescent fluororesin coating, comprising the steps of:

[0027] Step (1): Dissolving chlorotrifluoroethylene, cyclohexyl acrylate and ethylene trimethoxysilane in a mass ratio of 1: 1.2: 0.2 in n-butyl acetate to form a fluoropolymer with a solid content of 60% ;

[0028] Step (2): Weigh 120 parts of fluoropolymer obtained in step (1), 12 parts of isobutyl methacrylate, 8 parts of methyl methacrylate and 7 parts of isobornyl methacrylate, Dissolve 16 parts of cyclohexyl methacrylate and 6 parts of γ-methacryloxypropyl trimethoxysilane in xylene, and stir at 75°C for 12 hours under the catalysis of azobisisobutyronitrile to obtain fluorine resin;

[0029] Step (3): 100 parts of fluororesin obtained in step (2) in parts by weight, 22 parts of mixed solvent, 0.6 part of dispersant 983 and 0.5 part of 8900-20X anti-settling agent are stirred and dispersed at high speed until mixed Evenly, the stirring speed is 1200~1600 rpm,...

Embodiment 3

[0031] A preparation method of a weather-resistant pearlescent fluororesin coating, comprising the steps of:

[0032] Step (1): Dissolving chlorotrifluoroethylene, cyclohexyl acrylate and ethylene trimethoxysilane in a mass ratio of 1:1.1:0.15 in n-butyl acetate to form a fluoropolymer with a solid content of 55% ;

[0033] Step (2): Weigh 110 parts of fluoropolymer obtained in step (1), 11 parts of isobutyl methacrylate, 7 parts of methyl methacrylate and 6 parts of isobornyl methacrylate, Dissolve 14 parts of cyclohexyl methacrylate and 5 parts of γ-methacryloxypropyl trimethoxysilane in xylene, and stir at 70°C for 10 h under the catalysis of azobisisobutyronitrile to obtain fluorine resin;

[0034] Step (3): 100 parts of fluororesin obtained in step (2) in parts by weight, 18 parts of mixed solvent, 0.5 part of dispersant 983 and 0.3 part of 8900-20X anti-settling agent are stirred and dispersed at high speed until mixed Evenly, the stirring speed is 1200~1600 rpm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com