Acid alcohol resin for light-smell dope and preparation method of acid alcohol resin

An acid-alcohol resin and coating technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as unpleasant, difficult to eliminate odor, nausea, etc., and achieve good adhesion, stable gloss, and leveling. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

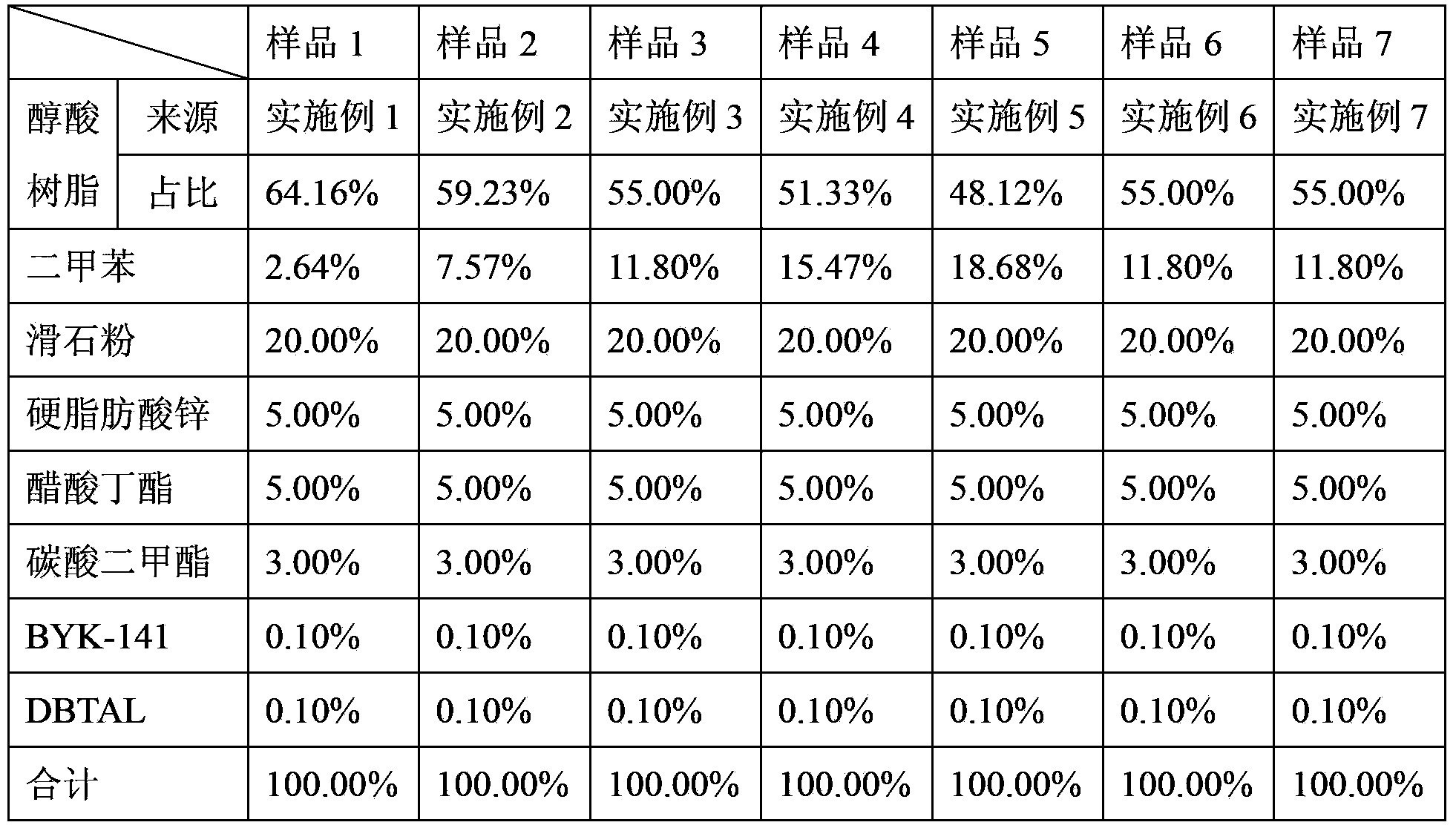

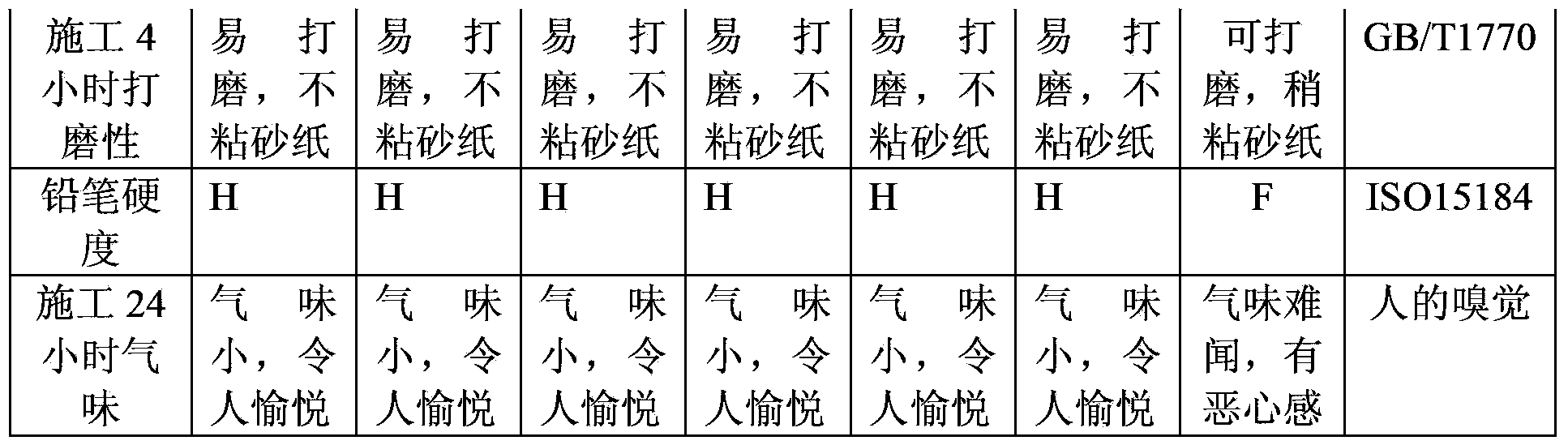

Examples

Embodiment 1

[0024] Add 13.40 parts of coconut oil, 11.66 parts of glycerin and 4.67 parts of trimethylolpropane into a 1000ml four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, pass into nitrogen for protection, start stirring and gradually heat up, until the temperature When the temperature rises to 120°C, add 0.01 part of lithium hydroxide, then raise the temperature to 235°C until the alcoholysis is qualified, then add 1.17 parts of dimer acid, 0.77 parts of succinic acid, 0.58 parts of maleic anhydride, 11.66 parts of phthalic anhydride, m- 11.66 parts of phthalic acid, 2.33 parts of terephthalic acid, 1.75 parts of triethylene glycol, 1.17 parts of neopentyl glycol, 1.17 parts of 2-methyl-1,3-propanediol, 5 parts of xylene, and then heat up to 200°C React until the acid value is below 18mgKOH / g, lower the temperature to 110°C, add 33.00 parts of xylene, stir evenly, and filter the material to obtain an acid value of less than 18mgKOH / g, a non-volatile co...

Embodiment 2

[0026] Add 21.2 parts of rapeseed oil, 5.3 parts of coconut oil, 5.3 parts of trimethylolethane, and 8.48 parts of pentaerythritol into a 1000ml four-necked flask equipped with a stirrer, reflux condenser and thermometer, and feed carbon dioxide gas for protection and start stirring And gradually heat up, when the temperature rises to 120°C, add 0.01 part of sodium hydroxide, then raise the temperature to 240°C until the alcoholysis is qualified, then add 1.06 parts of adipic acid, 0.53 parts of sebacic acid and 15.89 parts of phthalic anhydride when the temperature is lowered to 150°C , 4.77 parts of diethylene glycol, 0.85 parts of neopentyl glycol, 1.59 parts of 1,3-butanediol, 0.85 parts of 1,2-propanediol and 4 parts of xylene, and then heated to 210 ° C to react to an acid value of 18 mgKOH / g Below, lower the temperature to 110°C, add 15 parts of toluene and 15.17 parts of butyl acetate, stir evenly and filter the material to obtain an acid value of less than 18 mgKOH / g, ...

Embodiment 3

[0028] Add 9.37 parts of soybean oil, 11.11 parts of castor oil, 16.66 parts of trimethylolethane, and 2.22 parts of trimethylolpropane into a 1000ml four-neck flask equipped with a stirrer, reflux condenser and thermometer, and pass in carbon dioxide gas for protection , start stirring and gradually heat up. When the temperature rises to 120°C, add 0.02 parts of calcium hydroxide, then raise the temperature to 245°C until the alcoholysis is qualified, then add 29.3 parts of phthalic anhydride and 2.22 parts of neopentyl glycol after cooling down to 150°C. 4 parts of toluene, then heated up to 220 ° C to react until the acid value is below 18 mgKOH / g, cooled to 130 ° C, added 12.9 parts of xylene and 12.2 parts of butyl acetate, stirred evenly, filtered out the material, and the acid value was less than 18 mgKOH / g, The non-volatile content is 70%, and the color is less than 2# (iron-cobalt colorimeter). Alkyd resin for low-odor paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com