Pipe cap with glass lens optical window and manufacturing method of pipe cap

The technology of a glass lens and a manufacturing method, which is applied in the field of packaging shell manufacturing, can solve the problems of multiple processes, lens light window falling off, and high manufacturing cost, and achieve the effects of simple processing equipment, good connection firmness, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

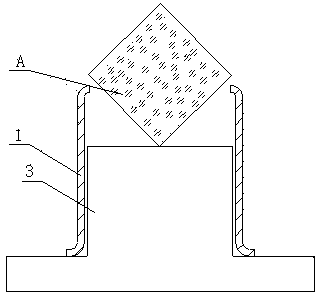

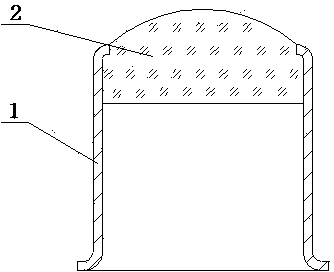

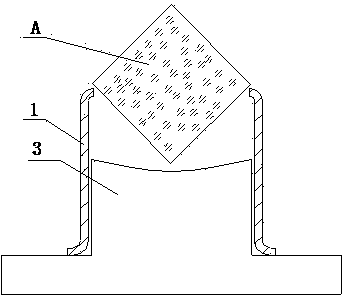

[0028] A method for making a tube cap with a glass lens light window, the tube cap with a glass lens light window is composed of a metal tube cap 1 and a glass light window 2, the upper end of the metal tube cap 1 is provided with a light-transmitting hole, and the glass lens is inlaid Form glass light window 2 in light-transmitting hole; Its innovation is: make the pipe cap with glass lens light window as follows:

[0029] 1) Prefabricated glass block and metal pipe cap 1 for spare;

[0030] 2) Insert the mold 3 into the metal pipe cap 1, and then place the glass block on the upper end surface of the mold 3; the shape of the mold 3 is cylindrical, and the upper end surface of the mold 3 is lower than the upper end surface of the metal pipe cap 1; the glass block, metal The structure formed by the pipe cap 1 and the mold 3 forms a blank;

[0031] 3) Send the blank into the high-temperature furnace, which is filled with wet nitrogen, and the temperature in the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com