Dual pressure feed transport system and transport method thereof

A technology of double-pressure conveying and compressed air, which is applied in the direction of conveyors, separation methods, and conveying bulk materials, etc., can solve the problems of short manufacturing cycle and achieve the effects of short manufacturing cycle, cost reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

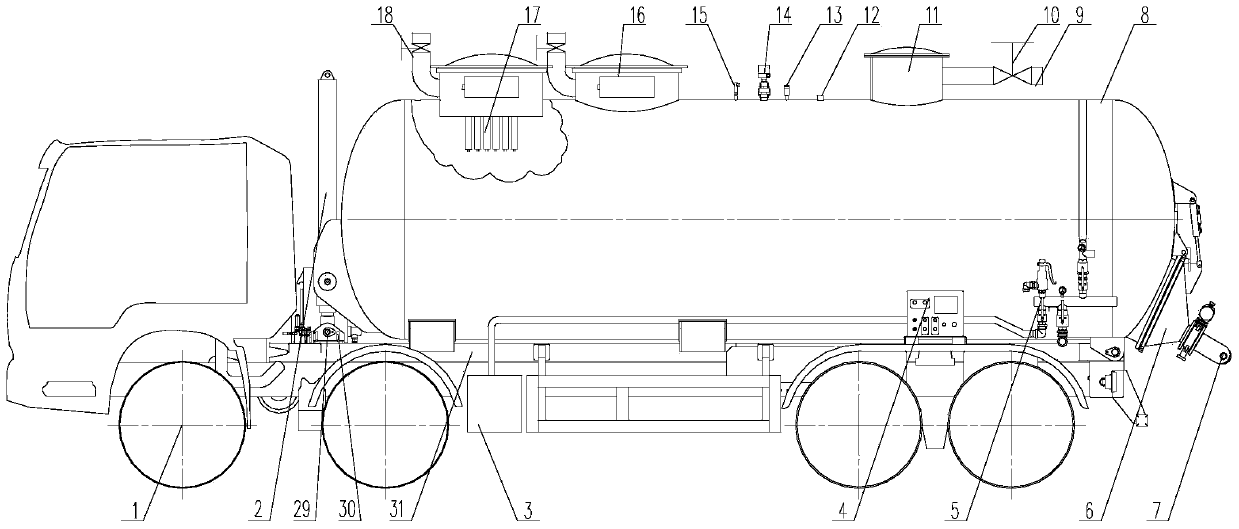

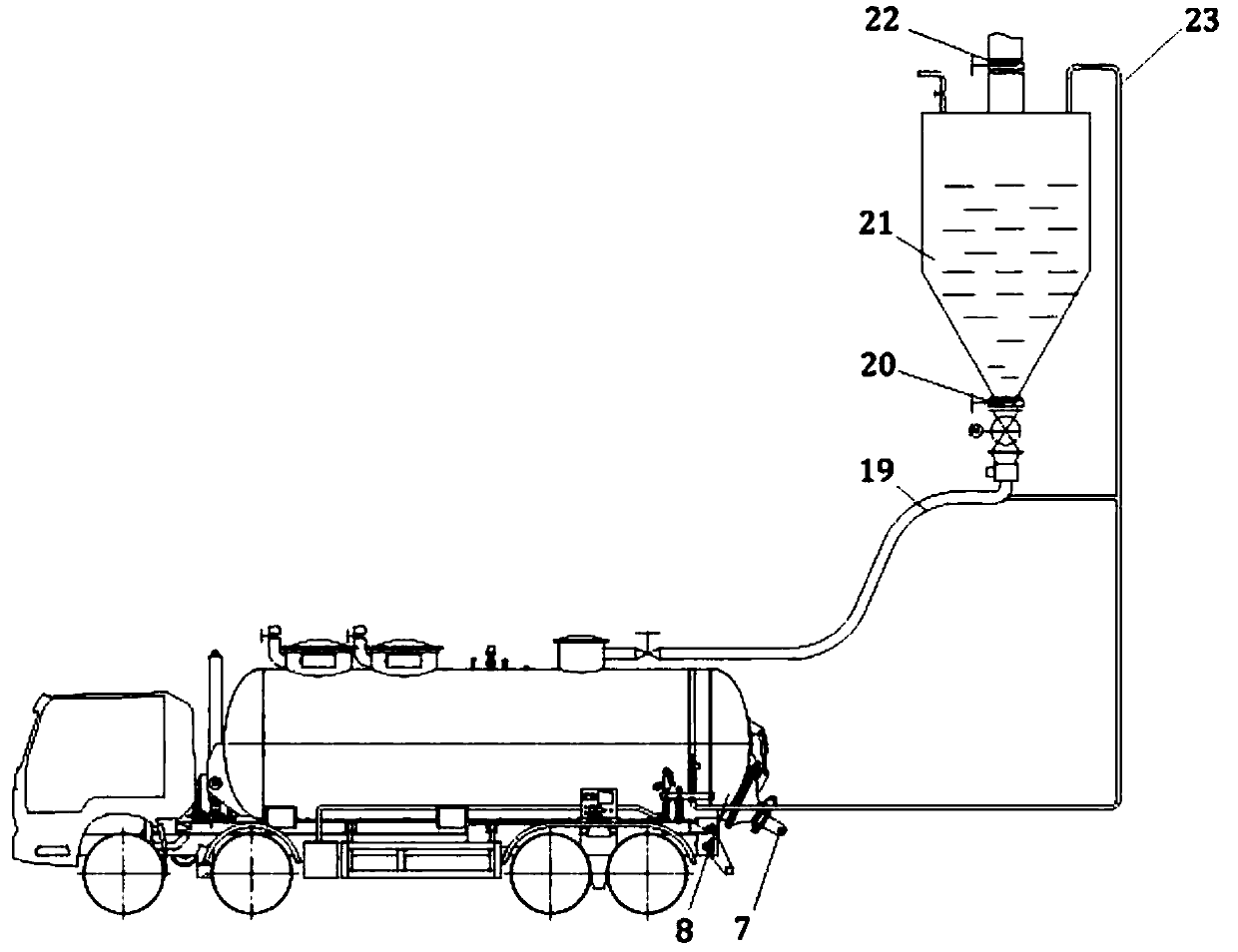

[0047] Such as figure 1 and figure 2 As shown, this embodiment includes: a double-pressure conveying vehicle and a receiving device or a discharging device connected thereto.

[0048] The described double-press delivery vehicle comprises: a chassis 1, a control cabinet 4 arranged on the chassis 1, and a main material tank 8 with a cyclone separator 11 and at least one filter and dust removal device 16, wherein: the cyclone separator 11 and the set The material inlet 9 with the inlet valve 10 is connected, and the main material tank 8 is respectively connected with the receiving equipment or the discharging equipment to realize dual-pressure conveying.

[0049] The described double-pressure conveying vehicle is preferably provided with a fluidizing device 6 with at least one air compressor 3 for fully mixing the material and air. The fluidizing device 6 is connected with the discharge equipment through a discharge hose 24, and the air The compressor 3 is connected to the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com