Monofilament filter cloth for coal washing and preparation method thereof

A monofilament and filter cloth technology, applied in the field of filter materials, can solve the problems of reducing the production efficiency of the loom, increasing the production cost, reducing the production efficiency, etc., and achieving the effects of improving the external appearance, prolonging the service life and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

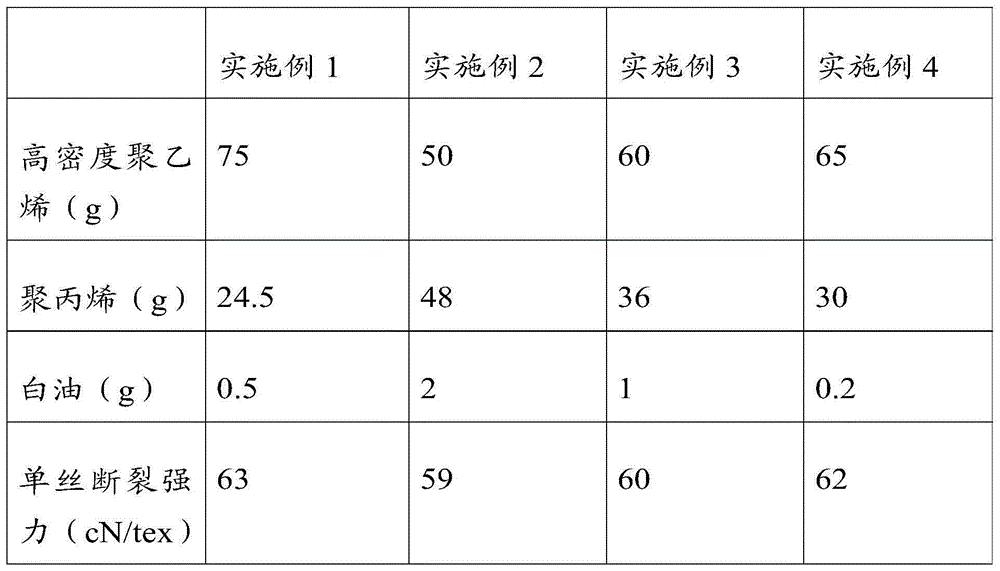

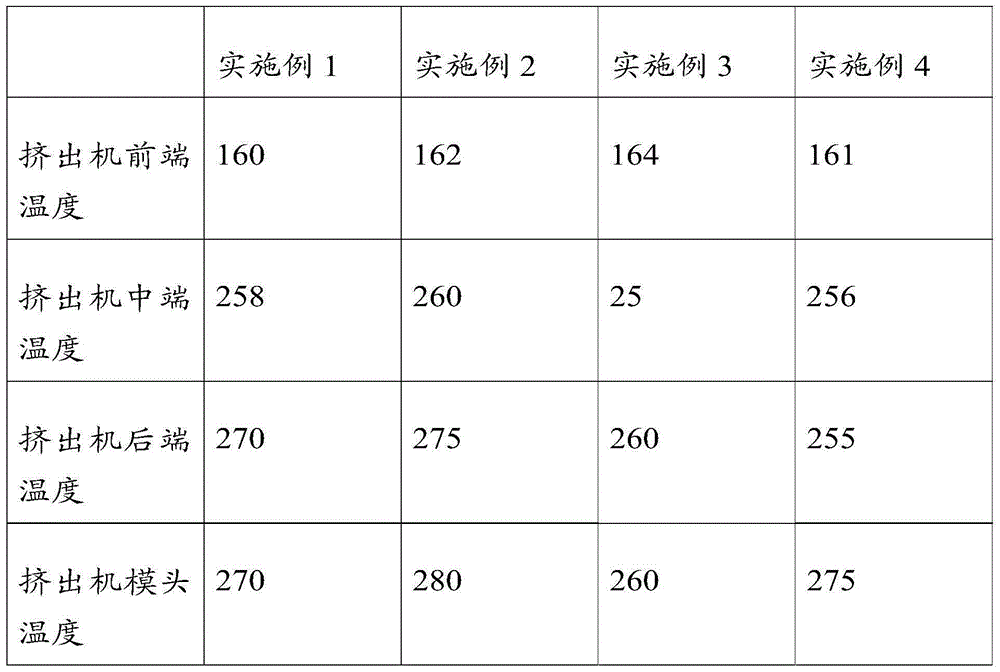

Embodiment 1-4

[0042] Table 2 embodiment 1-4 prepares the technological condition of monofilament filter cloth

[0043]

[0044]

[0045] The monofilament strength of the high-density polyethylene and polypropylene blended provided by Examples 1-4 can reach 59-63cN / tex, and the monofilament breakage will not occur when it is used for weaving, and the loom can be produced smoothly. Compared with polypropylene monofilament weaving, the production efficiency of the loom is greatly improved and the production cost is reduced.

[0046] The material, weight and breaking strength of the monofilament filter cloth for coal washing provided in Examples 5-8 are shown in Table 3.

[0047] The material, weight and breaking strength of the monofilament filter cloth for coal washing provided by table 3 embodiment 5-8

[0048]

[0049]

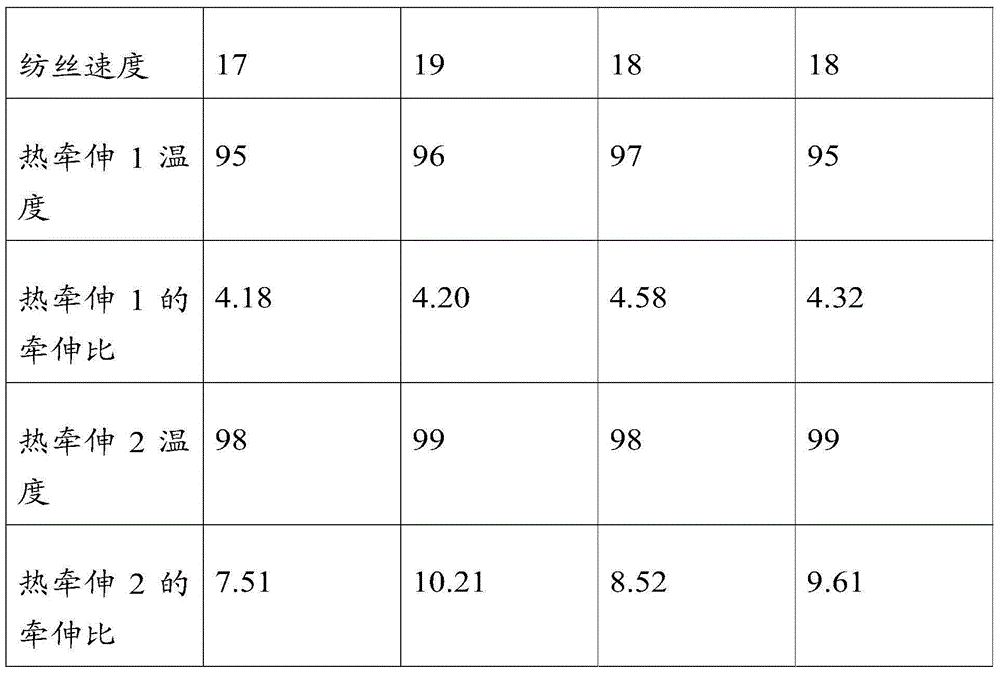

Embodiment 5-8

[0051] Table 4 embodiment 5-8 prepares the technological condition of monofilament filter cloth

[0052]

[0053]

[0054] The monofilament strength of high-density polyethylene and polypropylene blended provided by Examples 5-8 can reach 60-63cN / tex, and the situation of monofilament breakage will not occur when using it for weaving, and the loom can be produced smoothly. Compared with polypropylene monofilament weaving, the production efficiency of the loom is greatly improved and the production cost is reduced; at the same time, the monofilament filter cloth is green, which makes the surface of the filter cloth better and more attractive to consumers.

[0055] The material, weight and breaking strength of the monofilament filter cloth for coal washing provided in Examples 9-12 are shown in Table 5.

[0056] The material, weight and breaking strength of the monofilament filter cloth for coal washing provided by table 5 embodiment 9-12

[0057]

[0058]

Embodiment 9-12

[0060] Table 6 embodiment 9-12 prepares the technological condition of monofilament filter cloth

[0061]

[0062]

[0063] The monofilament strength of the high-density polyethylene and polypropylene blended provided by Examples 9-12 can reach 60-63cN / tex, and the monofilament breakage will not occur when using it for weaving, and the loom can be produced smoothly. Compared with the monofilament weaving made of polypropylene material, the production efficiency of the loom is greatly improved, and the production cost is reduced; meanwhile, in Examples 9-12, the matting agent can choose titanium dioxide and other substances that can whiten. Using matting agent as one of the raw materials to produce monofilament filter cloth can improve the optical reflection performance of the monofilament filter cloth surface, reduce the transparency of the monofilament filter cloth, and increase the whiteness of the monofilament filter cloth. The resulting monofilament filter cloth has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com