Polytetrafluoroethylene filament as well as preparation method and application thereof

A polytetrafluoroethylene and filament technology, which is applied in the field of polytetrafluoroethylene filament and its preparation, can solve problems such as uneven strength and poor evenness, and achieve reduced strength loss rate, low production cost, and stable dimensions good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

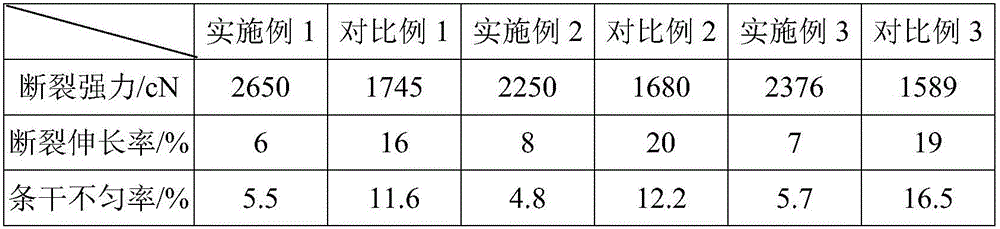

Examples

Embodiment 1

[0057] The preparation process of polytetrafluoroethylene filament is as follows:

[0058] (1) Lamination and degreasing: Two layers of PTFE calendered base tapes (0.25mm in thickness and 23cm in width) are alternately unwound and stacked clockwise and counterclockwise respectively, and fed to the roller degreasing and bonding device, Carry out overlapping degreasing;

[0059] Among them, through the tension device and the correction device, the two layers of calendered base belts are aligned and completely bonded to form a two-layer laminated base belt; Oil time is 6 seconds;

[0060] (2) Carry out two longitudinal heating and drawing of the two-layer laminated base belt after lamination and degreasing in step (1): the first drawing temperature is 200°C, the feeding speed is 6m / min, and the output speed is 12m / min ;The second drawing temperature is 275°C, the feeding speed is 2m / min, and the output speed is 10m / min;

[0061] (3) The two-layer laminated base tape after step...

Embodiment 2

[0067] The preparation process of polytetrafluoroethylene filament is as follows:

[0068] (1) Lamination and degreasing: Three-layer PTFE calendered base tape (thickness 0.25mm, width 23cm) is alternately unwound and stacked clockwise and counterclockwise respectively, and fed to the roller degreasing and bonding device, Carry out overlapping degreasing;

[0069] Among them, the three-layer calendered base belt is aligned and fully bonded to form a three-layer laminated base belt through the tension device and the correction device; Oil time is 5 seconds;

[0070] (2) The three-layer laminated base belt after step (1) laminated and degreased is subjected to longitudinal heating and drawing twice: the first drawing temperature is 210°C, the feeding speed is 6m / min, and the output speed is 12m / min ;The second drawing temperature is 285°C, the feeding speed is 2m / min, and the output speed is 12m / min;

[0071] (3) The three-layer laminated base tape after step (2) is heated an...

Embodiment 3

[0077] (1) Lamination and degreasing: Three-layer PTFE calendered base tape (thickness 0.25mm, width 23cm) is alternately unwound and stacked clockwise and counterclockwise respectively, and fed to the roller degreasing and bonding device, Carry out overlapping degreasing;

[0078] Among them, the three-layer calendered base belt is aligned and fully bonded to form a three-layer laminated base belt through the tension device and the correction device; Oil time is 7 seconds;

[0079] (2) The three-layer laminated base belt after step (1) laminated and degreased is subjected to longitudinal heating and drawing twice: the first drawing temperature is 190°C, the feeding speed is 4m / min, and the output speed is 8m / min ;The second drawing temperature is 260°C, the feeding speed is 3m / min, and the output speed is 12m / min;

[0080] (3) The three-layer laminated base tape after step (2) is heated and drawn is cut into 32 flat filaments in a cutting device;

[0081] (4) the flat wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com