Novel biodegradable vascular stent preparation method

A vascular stent, biological technology, applied in filament/wire forming, medical science, textiles and paper making, etc., can solve the problem of stent shape accuracy, poor surface quality, mechanical strength, stent thickness and cross-sectional area increase, stent structure Problems such as poor preparation repeatability, to achieve the effect of easy industrial automation, not easy to thrombosis, mechanical strength and volume advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Calculated from the volume of the stent with a 10% material margin, the amount of material required to calculate the stent is 0.2g, weigh the required amount of PPDO granular material with an electronic scale, and place it on an aluminum alloy that is suitable for the shape of the stent In the alloy mold, heat it with an electric heat gun until it melts, and after cooling, get the PPDO blank;

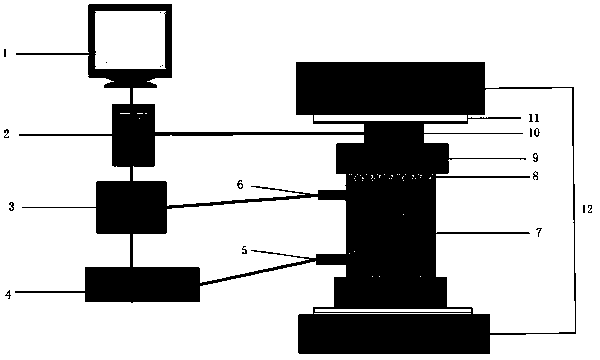

[0029] 2) A set of preparation equipment is composed of self-made mold, temperature controller, heating rod, 24V power supply, clamping device, pressure sensor, heat-insulating asbestos cloth, data acquisition card, and computer monitoring system. Its line is attached figure 1 connected as shown;

[0030] Pressure temperature Holding time cooling rate pressure 90℃ 10min 3.5℃ / min 5×10 3 N

[0031] 4) Put the mold in the clamping device, set the temperature of the thermostat to 90°C, when the thermostat reaches the set value, place the blank in the...

Embodiment 2

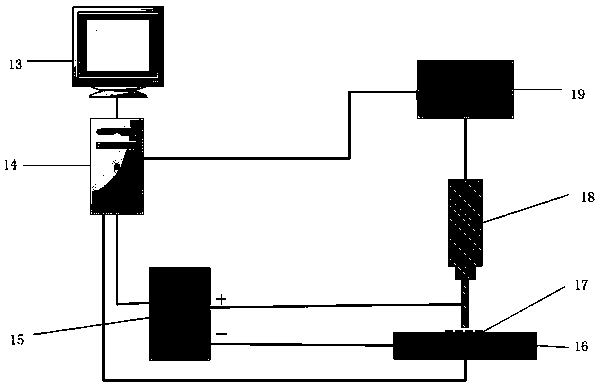

[0035] This example is basically the same as Example 1, except that 0.1g of PLLA is weighed with an electronic scale, dissolved in 1.6ml of trifluoroethanol, stirred and oscillated until completely dissolved, and a concentration of 6.25% (g / ml) of PLLA is obtained. Electrospinning solution; set the fiber spacing of direct-writing electrospinning to 40 μm, and the needle diameter of the barrel is 0.4 mm. By adjusting the computer control system, the voltage is 1 kV, the receiving distance is 0.5 mm, and the feeding speed is 0.2μl / h, the horizontal movement speed of the receiving platform is 150mm / s, and a layer of electrospinning is directly written, and finally a new type of biodegradable vascular stent composited with micron mesh PLLA film is obtained.

Embodiment 3

[0037] This example is basically the same as Example 1, except that 0.1g of PLGA is weighed with an electronic scale, dissolved in 1.6ml of trifluoroethanol, stirred and oscillated until completely dissolved, and a concentration of 6.25% (g / ml) of PLGA is obtained. Electrospinning solution; set the fiber spacing of direct-writing electrospinning to 40 μm, and the needle diameter of the barrel is 0.4 mm. By adjusting the computer control system, the voltage is 1.1 kV, the receiving distance is 0.5 mm, and the feeding speed 0.2μl / h, the horizontal movement speed of the receiving platform is 180mm / s, and a layer of electrospinning is directly written, and finally a new type of biodegradable vascular stent composited with micron mesh PLGA film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com