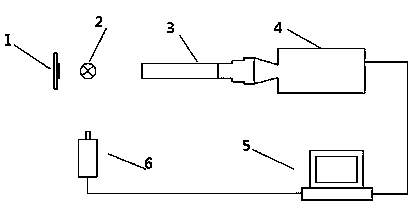

Image method measuring device and method for gas-liquid two-phase flow in pipelines

A gas-liquid two-phase flow and measurement device technology, which is applied in the direction of measurement devices, material analysis through optical means, instruments, etc., can solve problems such as inability to obtain, flow interference, and inability to obtain multiple parameters at the same time, so as to improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Such as figure 2 As shown, for the opaque pipe section, the corresponding transparent window 7 is processed and connected to the pipe section, so that the shape and size of the channel in the window are the same as the shape and size of the inner wall of the pipe, that is, the window 7 is used to replace the transparent pipe 2. The measurement steps are the same as in Example 1. The process is the same.

[0036] In the above two embodiments, the illumination light source adopts halogen light source, xenon light source or semiconductor light source; laser light source adopts visible light laser; telecentric lens adopts zoom or non-zoom telecentric lens; image sensor adopts CCD or CMOS devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com