Two-segment enveloping worm end face meshing worm transmission device

A technology of worm drive and enveloping ring, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of insufficient load-carrying capacity worm throat stiffness, automatic elimination, and many meshing teeth, etc. The effect of popularization, large bearing capacity and large number of meshing teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

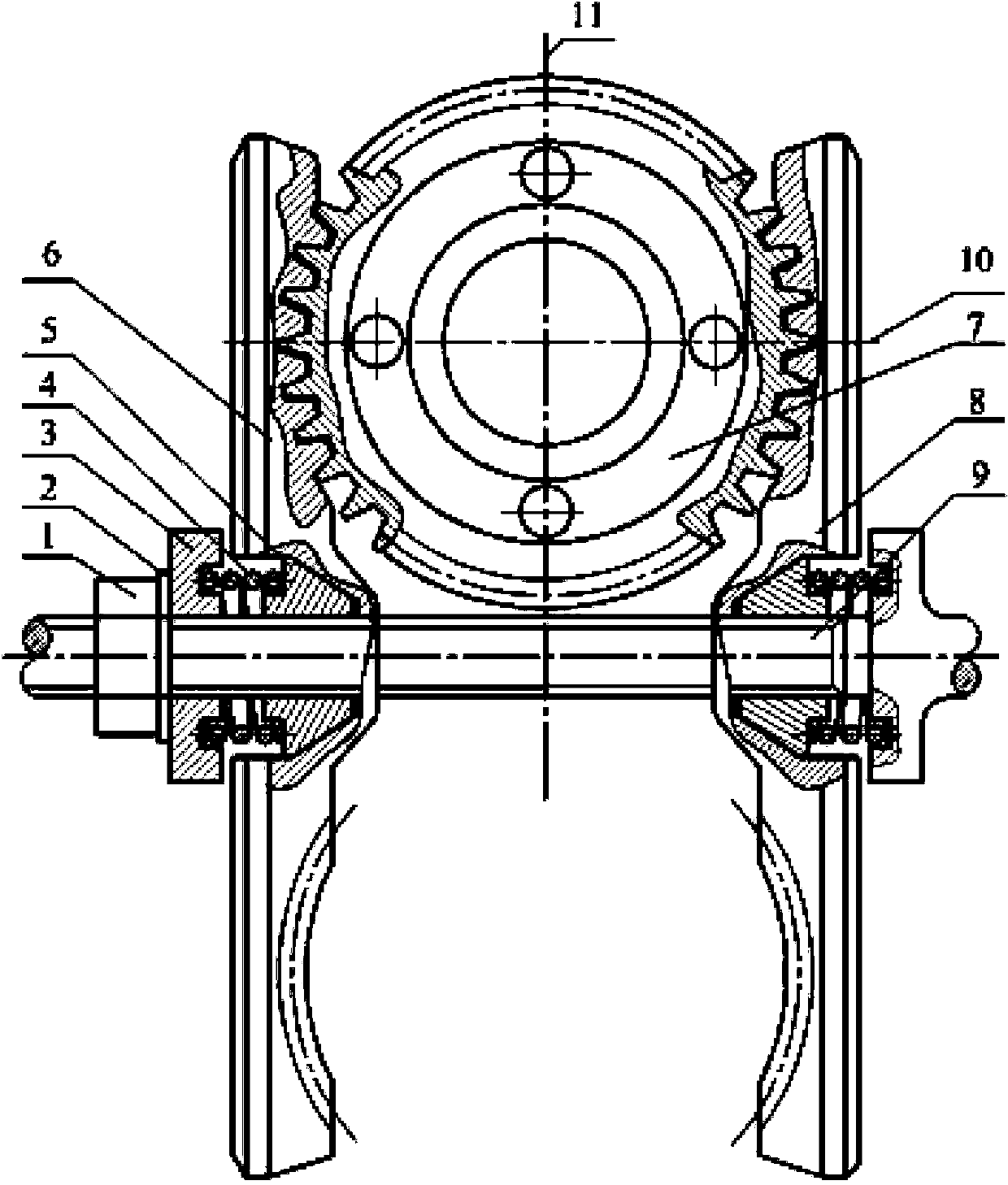

[0030] In this embodiment, the structure of the two-stage enveloping toroidal end meshing worm gear is as follows: figure 1 As shown, it includes a worm wheel 7, a left section worm 6, a right section worm 8, a connecting shaft 9 and two sets of axial positioners for adjusting the meshing backlash of the worm and worm gear. The connecting shaft 9 is a spline shaft, such as Figure 4 , Figure 5 shown. The left section worm 6 and the right section worm 8 are taken from the end face of the plane enveloping toroidal worm and have the same shape and structure. The position where their tooth surfaces mesh with the tooth surfaces on both sides of the worm wheel is that the worm wheel is parallel to the centerline 10 of the connecting shaft. The upper part and the lower part, their inner holes are keyway structures that match the spline shaft. The two sets of axial positioners are composed of spring seat 3, adjustment spring 4 and positioning head 5, wherein the spring seat 3 and ...

Embodiment 2

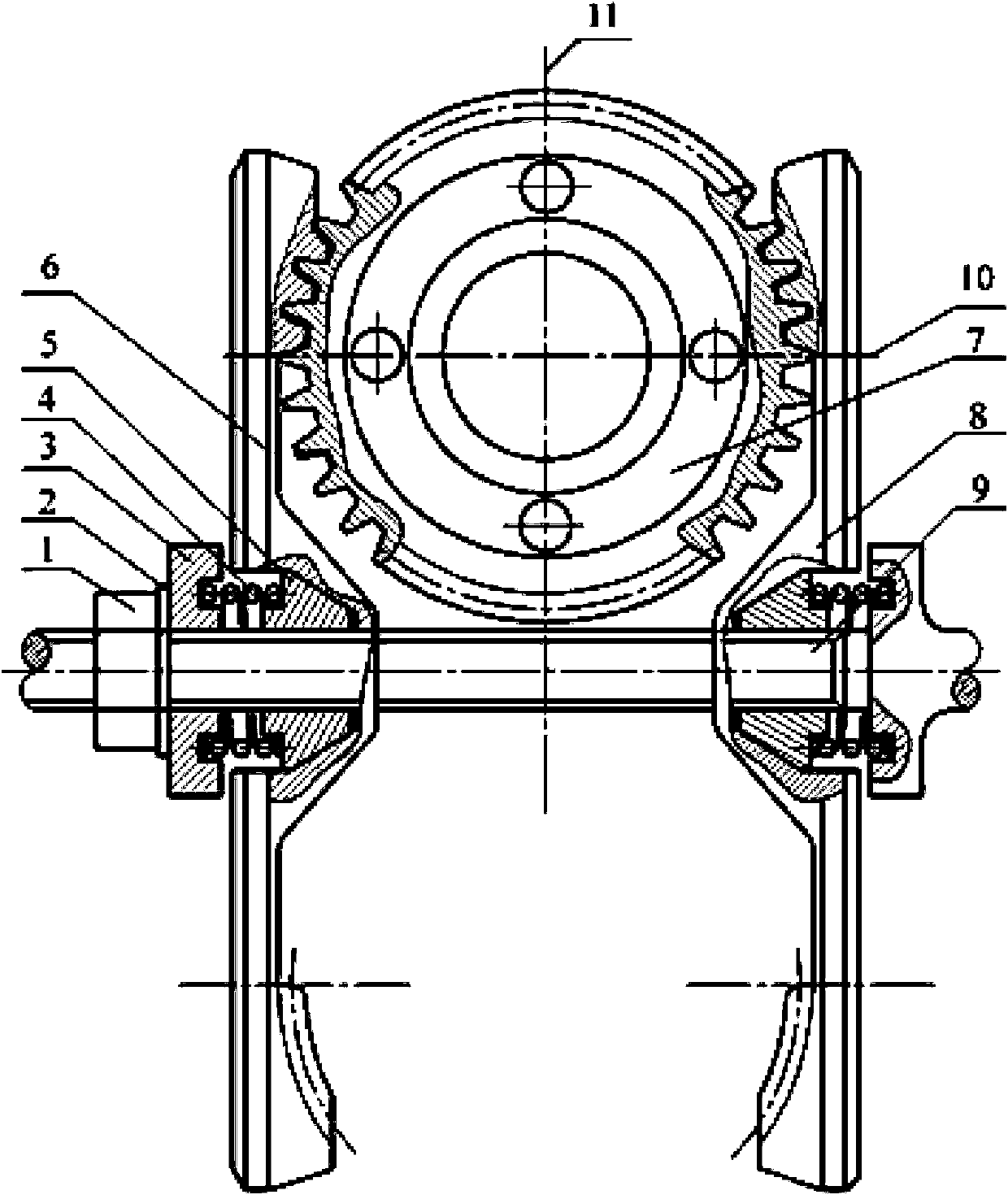

[0033]In this embodiment, the structure of the two-stage enveloping toroidal end meshing worm gear is as follows: figure 2 As shown, it includes a worm wheel 7, a left section worm 6, a right section worm 8, a connecting shaft 9 and two sets of axial positioners for adjusting the meshing backlash of the worm and worm gear. The difference from Embodiment 1 is that the tooth surfaces on both sides of the worm wheel are located above the center line 10 of the worm wheel parallel to the connecting shaft, respectively meshing with the tooth surfaces of the left section worm 6 and the right section worm 8, and the left section worm 6 and the right section worm The structure of section worm screw 8 matches it.

Embodiment 3

[0035] In this embodiment, the structure of the two-stage enveloping toroidal end meshing worm gear is as follows: figure 2 As shown, it includes a worm wheel 7, a left section worm 6, a right section worm 8, a connecting shaft 9 and two sets of axial positioners for adjusting the meshing backlash of the worm and worm gear. The difference from Embodiment 1 is that the tooth surfaces on both sides of the worm wheel are located below the centerline 10 of the worm wheel parallel to the connecting shaft, respectively meshing with the tooth surfaces of the left section worm 6 and the right section worm 8, and the left section worm 6 and the right section worm The structure of section worm screw 8 matches it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com