Gas turbine turbocharger suitable for coke oven gas internal combustion engine

A technology of turbocharger and coke oven gas, which is applied in the field of turbocharger and can solve the problem of inapplicability of gas turbine turbocharger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

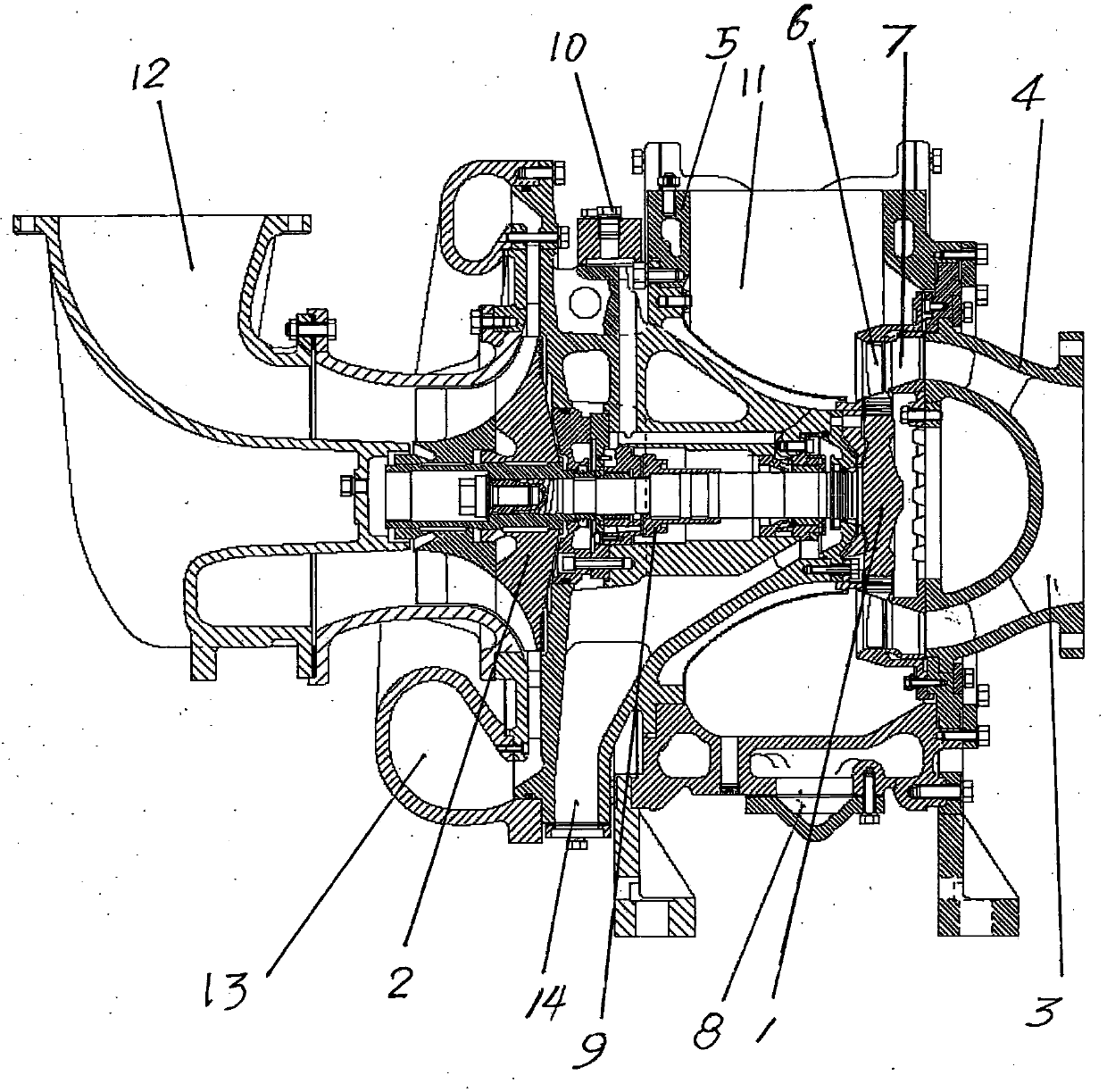

[0023] A gas turbine turbocharger suitable for coke oven gas internal combustion engines, consisting of an axial flow exhaust gas turbine and a centrifugal compressor, the two are coaxially supported by built-in floating bearings and thrust bearings supplied with external oil at 20,000 to 50,000rpm High-speed rotation, the high-temperature gas discharged from the internal combustion engine of the turbine enters the nozzle ring through the intake shell and expands to generate high-speed airflow to drive the turbine to rotate at high speed, driving the compressor impeller to rotate at high speed, fresh air enters the impeller through the silencer and rotates at high speed to obtain high-speed blade diffuser The diffuser merges into the volute to form high-pressure air into the intake port of the internal combustion engine, forming fresh air charge and scavenging air, increasing the fresh air charge, increasing the charge of coke oven gas, and increasing the output power of the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com