UV curing resin, preparation method thereof and application of UV curing resin in UV curing colored paint

A technology for curing resins and paints, applied in applications, household appliances, coatings, etc., can solve problems such as energy consumption, poor adhesion of coating films, poor wetting of pigments and fillers, etc., to achieve good wettability, guarantee Color uniformity, solve the effect of hard curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. UV curable resin

[0031] (1) Preparation

[0032] (a) Add 70g of pentaerythritol, 74g of phthalic anhydride and 200g of linoleic acid into a reactor equipped with a thermometer, stirring paddle, reflux condenser and water separation device, add reflux solvent xylene, and react at 200°C for 6h , the acid value of the system was below 10mgKOH / g, and 282g alkyd resin was obtained by cooling down.

[0033](b) Mix 60g of hydroxyhexyl methacrylate and 110g of isophorone diisocyanate, add 0.3g of hydroquinone inhibitor and 0.5g of triethylamine to react at 80°C for 2 hours, and the mass fraction of hydroxyl groups is 0.3 %, make 170g acrylic modified polyurethane.

[0034] (c) React 170 g of the acrylic-modified polyurethane obtained above with 120 g of the alkyd resin prepared in step (a) at 80° C. for 3 hours to obtain 290 g of UV-curable resin.

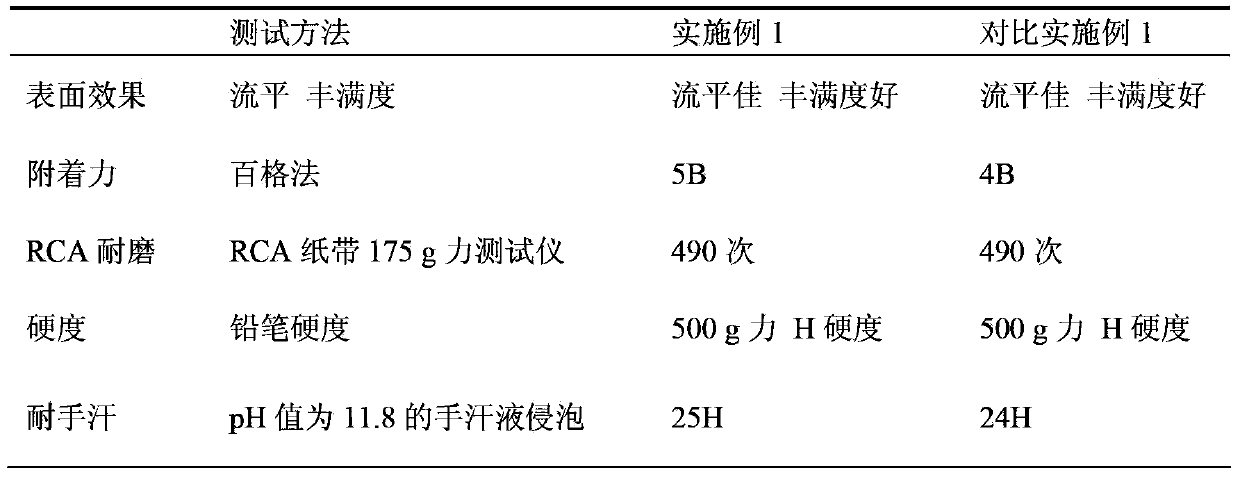

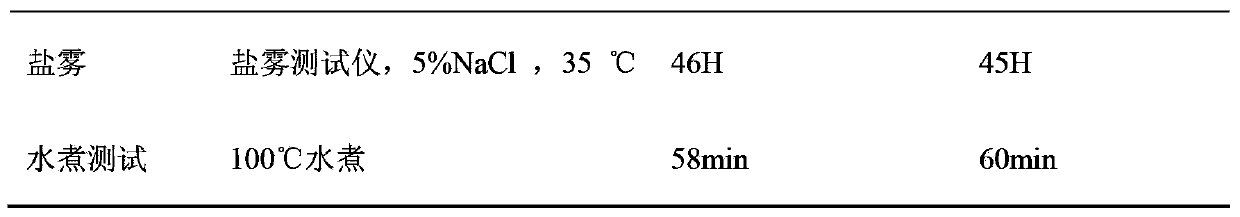

[0035] (2) Performance, as shown in Table 1. The appearance is clear and transparent and the color is light, which is con...

Embodiment 2

[0052] 1. UV curable resin

[0053] (1) Preparation

[0054] (a) Add 90g of trimethylolpropane, 80g of isophthalic acid and 210g of oleic acid into a reactor equipped with a thermometer, a stirring paddle, a reflux condenser and a water separation device, add the reflux solvent xylene, and heat at 220°C After 5 hours of reaction, the acid value of the system was below 15 mgKOH / g, and 330 g of alkyd resin was obtained by cooling down.

[0055] (b) Mix 40g of hydroxyhexyl acrylate and 90g of isophorone diisocyanate, add 0.3g of hydroquinone inhibitor and 0.4g of dibutyltin dilaurate and react at 70°C for 2h, and the mass fraction of hydroxyl groups reaches 0.3 % or less, a semi-adduct containing an NCO group at one end is made.

[0056] (c) 130 g of the acrylic modified polyurethane prepared above was reacted with 120 g of the alkyd resin prepared in step (a) at 70° C. for 2.5 hours to obtain 250 g of the alkyd modified polyurethane acrylic resin.

[0057] (2) Performance, as...

Embodiment 3

[0082] 1. UV curable resin

[0083] (1) Preparation

[0084] (a) Add 30g of pentaerythritol, 20g of neopentyl glycol, 40g of phthalic anhydride and 130g of linolenic acid into a reactor equipped with a thermometer, stirring paddle, reflux condenser and water separator, and add the reflux solvent xylene, React at 210°C for 6 hours, the acid value of the system is below 15mgKOH / g, cool down and prepare 200g of alkyd resin for later use.

[0085] (b) Mix 20g of hydroxypropyl acrylate and 70g of isophorone diisocyanate, add 0.3g of hydroquinone polymerization inhibitor and 0.5g of triethylenediamine and react at 75°C for 2 hours, and the mass fraction of hydroxyl groups reaches 0.3%. Next, 90 g of a semi-adduct product containing an NCO group at one end was prepared.

[0086] (c) React 90 g of the acrylic-modified polyurethane semi-adduct obtained above with 110 g of the alkyd resin prepared in step (a) at 75° C. for 3 hours to obtain 200 g of UV curable resin.

[0087] (2) Per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com