Wastewater recycling process for waste paper pulping and manufacturing bobbin paper

A waste water recovery and treatment process technology, applied in the direction of process waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as system corrosion, odor product quality, decline, etc., to reduce pollution , System power requirements are low, reducing the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

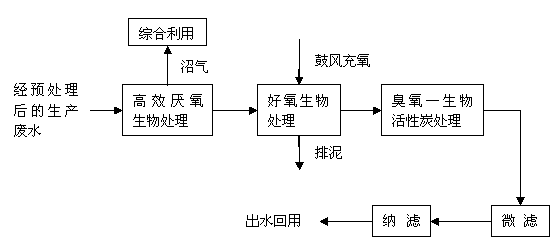

[0038] Example 1 A waste paper pulping process for the recycling and utilization of bobbin paper waste water. The waste water is successively subjected to high-efficiency anaerobic biological treatment, aerobic biological treatment, ozone-biological activated carbon treatment, microfiltration and nanofiltration treatment. Effluent water recycling.

Embodiment 2

[0039] Example 2 A waste paper pulping process for the recycling and utilization of bobbin paper waste water. The waste water is successively subjected to high-efficiency anaerobic biological treatment, aerobic biological treatment, ozone-biological activated carbon treatment, microfiltration and nanofiltration treatment. Effluent water recycling.

[0040] The high-efficiency anaerobic biological treatment refers to: the wastewater is first treated by hydrolysis and pre-acidification, using hydrolysis anaerobic microorganisms to remove part of the organic pollutants, and the effluent undergoes anaerobic fermentation to decompose most of the refractory organic matter in the wastewater and produce CH 4 Bioenergy.

[0041] The aerobic biological treatment refers to removing most of the organic pollutants in the water by means of the adsorption, oxidation and degradation of aerobic microorganisms in the aeration tank, and the effluent from the aeration tank flows into the secondar...

Embodiment 3

[0045] Example 3 A waste paper pulping manufacturing bobbin paper waste water recycling process, the steps are basically the same as in Example 2, the difference is that before the waste water is hydrolyzed and pre-acidified, it is first treated by a pre-treatment facility to remove the waste water. Large floating solids, recycle longer fibers, and adjust water quality and water volume. The pretreatment facilities are grid water collection wells, inclined nets, sedimentation tanks and / or adjustment tanks, and the grid spacing in the grid water collection wells 15-25mm, inclined net 100-150 mesh. When the wastewater is treated by hydrolysis and pre-acidification, the parameters are controlled as follows: the hydraulic retention time is 6-8h, the dissolved oxygen concentration is ≤0.5mg / L, and the reaction temperature is maintained at 25-30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com