Metal silicide catalyst of selective hydrogenation 1,4-butynediol and application of metal silicide catalyst

A metal silicide and selective hydrogenation technology, which is applied in the field of fine chemicals, can solve the problems of low yield of 1,4-butenediol, easy loss of catalyst active components, and no consideration of catalyst stability, and achieves the goal of inhibiting accumulation. Carbon, good prospects for industrial applications, the effect of enhancing fluctuating adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of Raney type nickel silicide catalyst

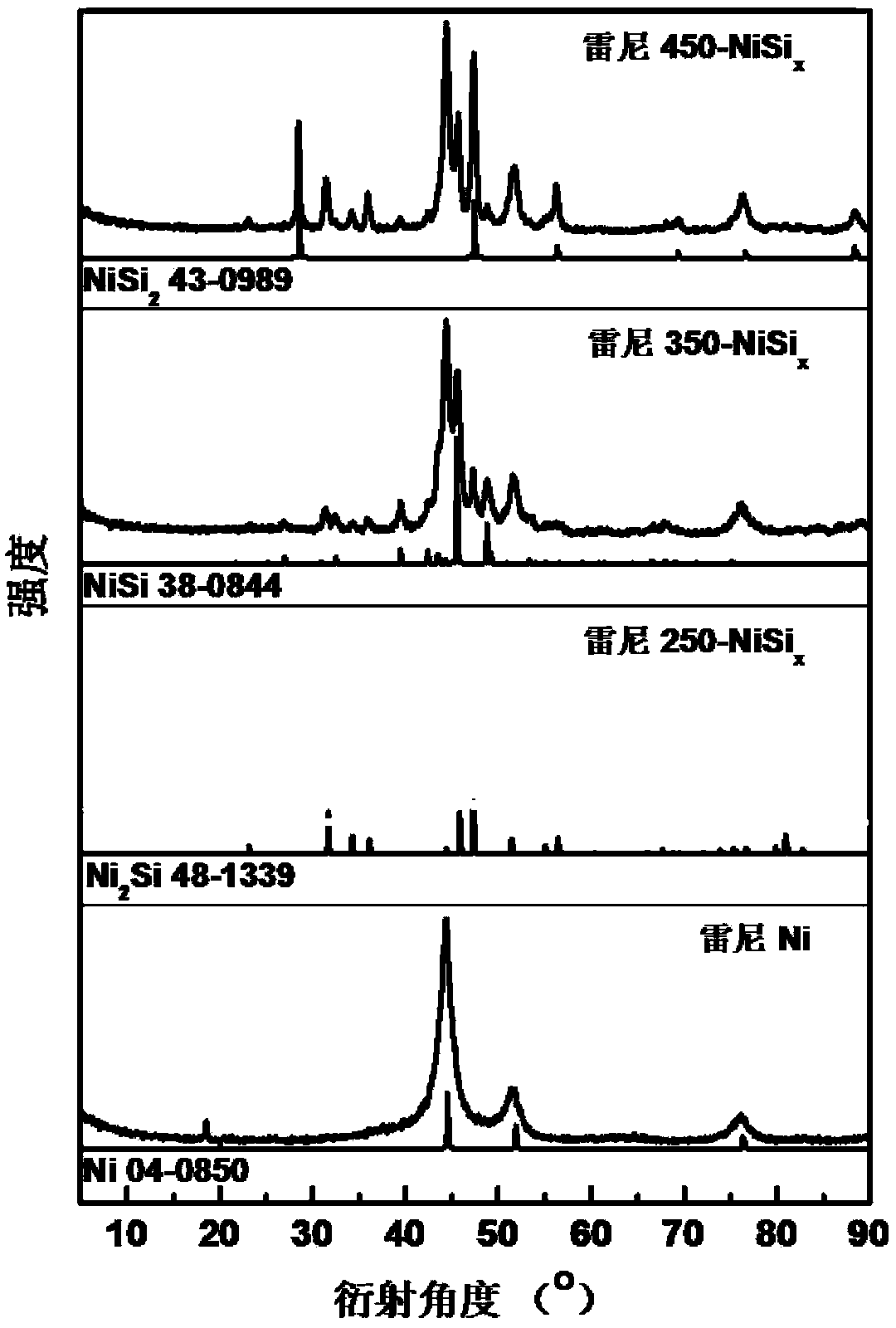

[0022] Activate 0.3g of Raney-type nickel at 200°C for 2h under a hydrogen atmosphere, and then pass through 10% SiH 4 / H 2 The temperature of the mixed gas was raised to the silicide reaction, reacted at 250°C, 350°C, and 450°C for 15 minutes, and cooled to room temperature under an inert atmosphere to obtain Raney-type nickel silicide catalysts in different phases. Its specific phase changes are as attached figure 1 Shown in the XRD spectrum.

Embodiment 2

[0023] Embodiment 2: the preparation of cobalt silicide catalyst

[0024] Reduce 0.5g of cobalt oxide at 400°C for 2h under hydrogen atmosphere, then pass H 2 Carries 10% CH 3 SiCl 3 The saturated steam was programmed to heat up to 600°C for silicide reaction for 60 minutes, and cooled to room temperature under an inert atmosphere to obtain a cobalt silicide catalyst.

Embodiment 3

[0025] Embodiment 3: the preparation of PdSi / SBA-15 catalyst

[0026] Activate 0.3g of 1%Pd / SBA-15 at 200°C for 2h under a hydrogen atmosphere, and then pass in H 2 Carries 10% HSiCl 3 The saturated steam was programmed to heat up to 300°C for silicide reaction for 60 minutes, and cooled to room temperature under an inert atmosphere to obtain a PdSi / SBA-15 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com