Dendrocalamus oil microcapsule and preparation method thereof

A technology of sesame oil and microcapsules, which is applied in the direction of food preparation, application, food science, etc., can solve the problems affecting the application prospect and development of sesame oil, nutrient loss, and nutritional value limitation, etc., and achieve good marketability, propulsion, and expansion Application space, increase the effect of the application path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

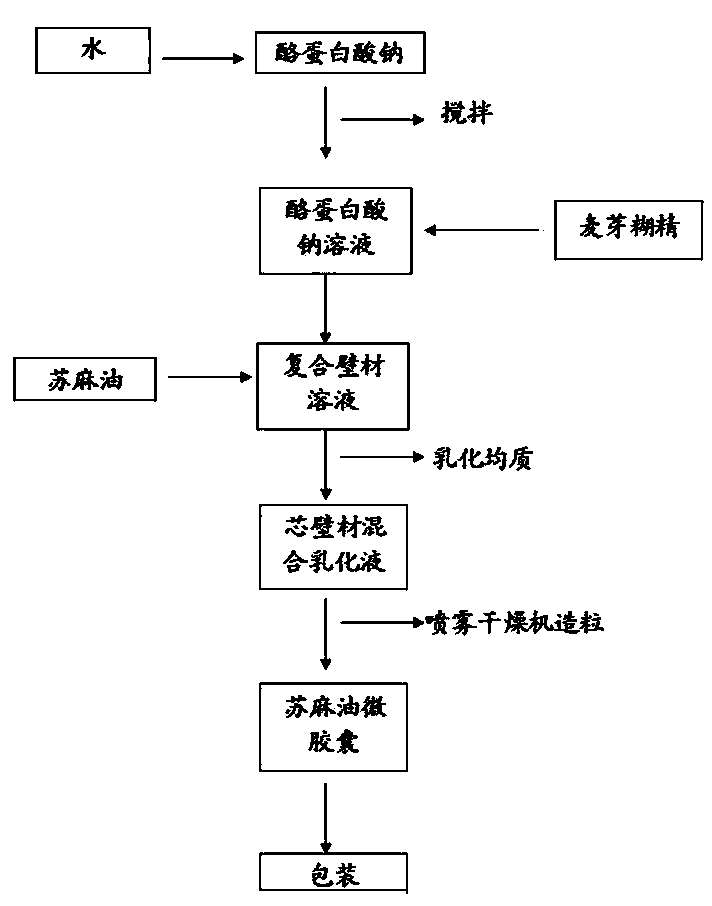

Method used

Image

Examples

Embodiment 1

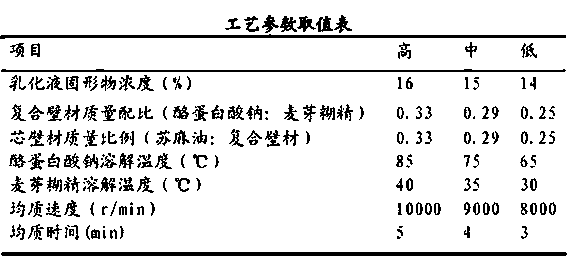

[0022] During the test, each step uniformly takes the highest column value in the process parameter value table, and the specific operation steps are as follows:

[0023] 1. The total mass of the emulsion is 100g, the solid content is 16g, the sodium caseinate is 2.98g, the maltodextrin is 9.05g, and the sesame oil is 3.97g, and each substance is weighed.

[0024] 2. Weigh 2.98g of sodium caseinate and dissolve it in 84g of distilled water with stirring. The dissolution temperature is 85°C. After the sodium caseinate was completely dissolved and cooled to 40°C, 9.05g of maltodextrin was stirred and dissolved therein. After the wall material was completely dissolved, the wall material solution was cooled to room temperature and 3.97g of sesame oil was added. After the core and wall materials are evenly stirred, a mixture of core and wall materials is obtained.

[0025] 3. Place the above emulsion in a homogenizer and homogenize at a speed of 10000r / min for 5 minutes to fully ...

Embodiment 2

[0029] During the test, each step uniformly takes the middle column value in the process parameter value table, and the specific operation steps are as follows:

[0030] 1. The total mass of the emulsion is 100g, the solid content is 15g, the sodium caseinate is 2.62g, the maltodextrin is 9.00g, and the sesame oil is 3.38g, and each substance is weighed.

[0031] 2. Weigh 2.62g of sodium caseinate and dissolve it in 85g of distilled water with stirring at 75°C. After the sodium caseinate is completely dissolved and cooled to 35°C, stir and dissolve 9.00g of maltodextrin in it. After the wall material is completely dissolved, cool the wall material solution to room temperature and add 3.38g of sesame oil. After the core and wall materials are evenly stirred, a mixture of core and wall materials is obtained.

[0032] 3. Place the above emulsion in a homogenizer and homogenize at a speed of 9000r / min for 4 minutes to fully emulsify the mixture of core and wall materials to obta...

Embodiment 3

[0036] During the test, each step uniformly takes the lower column value in the process parameter value table, and the specific operation steps are as follows:

[0037] 1. The total mass of the emulsion is 100g, the solid content is 14g, the sodium caseinate is 2.24g, the maltodextrin is 8.96, and the sesame oil is 2.80g, and each substance is weighed.

[0038] 2. First weigh 2.24g of sodium caseinate and dissolve it in 86g of distilled water with stirring, and the dissolution temperature is 65°C. After the sodium caseinate was completely dissolved and cooled to 30°C, 8.96g of maltodextrin was stirred and dissolved therein. After the wall material was completely dissolved, the wall material solution was cooled to room temperature and 2.80g of sesame oil was added. After the core and wall materials are evenly stirred, a mixture of core and wall materials is obtained.

[0039] 3. Place the above-mentioned emulsion in a homogenizer and homogenize it at a speed of 8000r / min for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com