Chemical test method for bipropellant thruster after thermal standard cleaning

A two-component thruster, chemical inspection technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problem of undiscovered chemical inspection methods, and achieve the effect of high precision requirements, guaranteed accuracy, and small thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

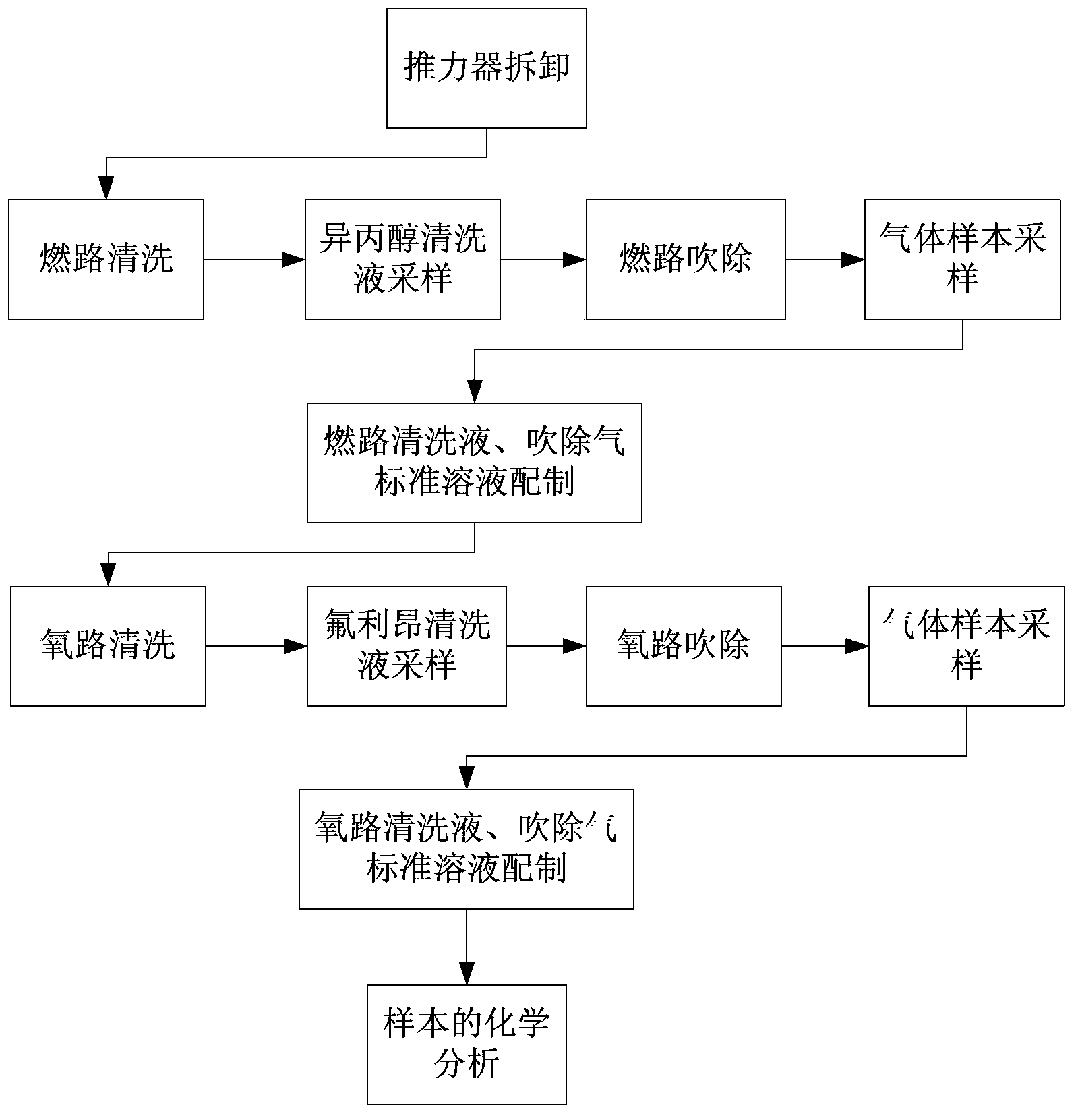

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0043] After the thermal scalar test of the dual-component thruster, in order to avoid the residual propellant from causing damage to the man-machine environment in subsequent tests, it was cleaned with a solvent compatible with the propellant. This method achieves the purpose of confirming the cleaning effect by inspecting and controlling the contents of the chemical components in the liquid phase and gas phase of the residual propellants (MON-1 and MMH) and the cleaning solution (isopropanol and Freon) after cleaning.

[0044] First, verify the compatibility of the propellant cleaning fluid (isopropanol and freon solution) with the thruster piping materials to confirm that the cleaning fluid does not have a negative impact on the thruster itself. Secondly, it is necessary to determine whether the thruster has achieved the cleaning purpose by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com