Method and device for pulse-type quantitative fuel injection

A fuel injection device and pulse-type technology, which is applied in the direction of combustion method, liquid fuel supply/distribution, fuel supply adjustment, etc., can solve the problem of inability to switch fuel injectors in time and accurately, quantitative fuel injection, and fuel combustion. Waste combustion efficiency and other issues, achieve the effect of precise control of fuel injection volume, continuous operation and reliability, and improve fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

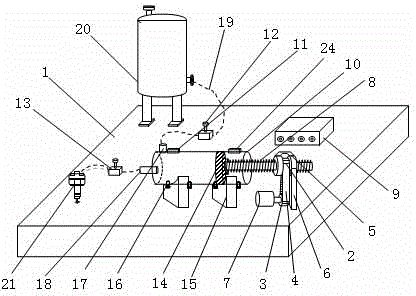

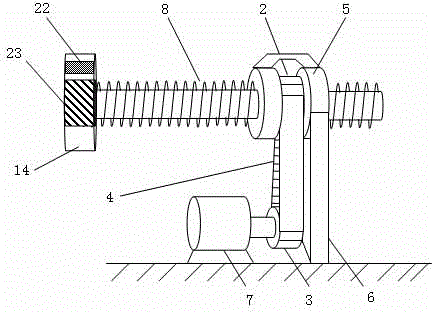

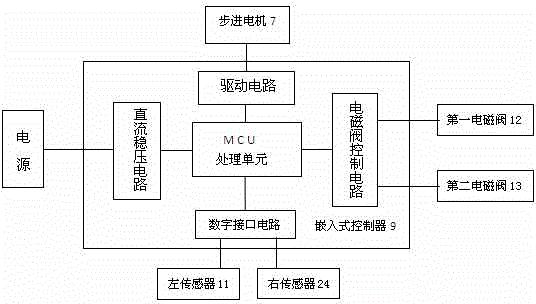

[0017] see figure 1 and figure 2 , the bottom of the present invention is a rigid base 1, on which a constant pressure oil storage tank 20 is fixedly installed, and the base 1 and the constant pressure oil storage tank 20 both form an integration. The constant pressure oil storage tank 20 connects the piston type to the several warehouses 10 through the oil delivery pipe 19, and supplies oil to the piston type to the several warehouses 10. The first electromagnetic valve 12 is installed on the oil delivery pipe 19 between the constant pressure oil storage tank 20 and the piston feeder warehouse 10 . The piston-type feeding chamber 10 is provided with an oil inlet port 17 and an oil outlet port 18 , and the constant pressure oil storage tank 20 is connected to the oil inlet port 17 through an oil delivery pipe 19 . The oil outlet port 18 is mechanically connected to the nozzle 21 through another oil delivery pipe 19, and the nozzle 21 adopts a mechanical large-flow nozzle, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com