Material, device and method for steel back/carbon fiber knitted fabric self-lubricating lining bearing

A technology of self-lubricating and knitted fabrics, applied to materials, devices and methods, which can solve problems such as low friction coefficient, easy peeling between layers, complex process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

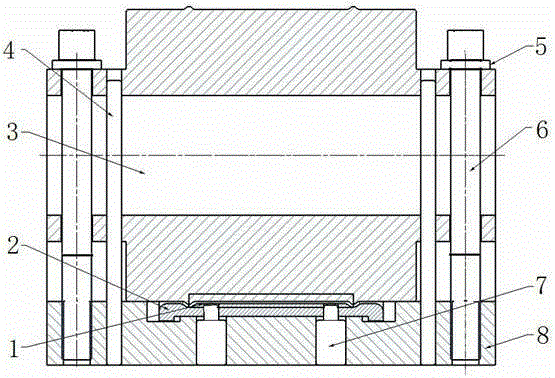

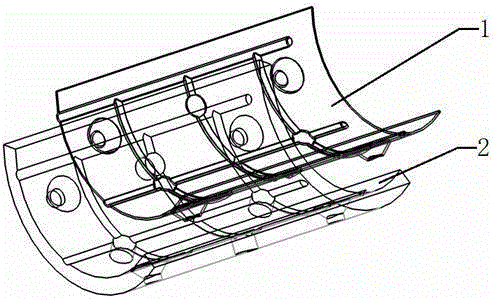

[0037] The steel back / composite material lining bearing bush of the present invention, the steel back / carbon fiber knitted fabric self-lubricating composite material lining bearing bush, the inner surface of the steel back 2 has a layer of knitted carbon fiber reinforced self-lubricating composite material lining 1. The lining layer 1 is molded and solidified on the inner surface of the steel back 2 through the pressure of the mold and bonded into one body.

[0038]The self-lubricating composite material of the lining layer of the present invention adopts carbon fiber knitted fabric as a reinforcing body, takes epoxy resin as a matrix, adds chopped carbon fiber in the matrix as a secondary reinforcement, and adds various modification, filling and lubricating ingredients, The concrete mass percent of each component is as follows:

[0039] Epoxy resin 40; toughening agent, dispersant 6; talcum powder 400 mesh, 5;

[0040] Graphite 2; molybdenum disulfide 10; chopped carbon fibe...

Embodiment 2

[0062] The method and device of this embodiment are the same as those of Embodiment 1, except that the carbon fiber knitted fabric reinforcement and the proportion of the lining material are different. The proportioning of the lining material in this embodiment is as follows:

[0063] Epoxy resin 40 toughening agent, dispersant 6 talcum powder 400 mesh 8

[0064] Graphite 2 molybdenum disulfide 15 carbon fiber 10 curing agent 19.

[0065] The aforementioned chopped carbon fibers have a length of 0.5 mm and a diameter of 7 microns.

[0066] The needle density of the above-mentioned carbon fiber knitted fabric is 5 needles / inch, and the diameter of the thread is 1.0 mm. It is formed by twisting two bundles of 1K and one bundle of 3K carbon fibers; in this embodiment, the diameter of the single filament is 7 microns.

[0067] In this embodiment, the carbon fiber knitted fabric is subjected to desizing, cleaning, nitric acid oxidation + coupling agent treatment, the desizing trea...

Embodiment 3

[0071] The method and device of this embodiment are the same as those of Embodiment 1, except that the carbon fiber knitted fabric reinforcement and the proportion of the lining material are different. The proportioning of the lining material in this embodiment is as follows:

[0072] Epoxy resin 45 toughening agent, dispersant 8 talcum powder 400 mesh 5

[0073] Graphite 3 molybdenum disulfide 10 carbon fiber 14 curing agent 15.0.

[0074] The aforementioned chopped carbon fibers have a length of 0.4 mm and a diameter of 5 microns.

[0075] The needle density of the above-mentioned carbon fiber knitted fabric is 6 needles / inch, and the diameter of the thread is 0.7 mm, which is formed by twisting 3 bundles of 1K carbon fibers; in this embodiment, each bundle of carbon fibers has 1000 carbon fiber monofilaments, and the diameter of the monofilaments is 9 microns .

[0076] In this embodiment, the carbon fiber knitted fabric is subjected to desizing, cleaning, nitric acid oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com