Manufacturing method for anode film of part of integrated circuit manufacturing equipment

A technology for manufacturing equipment and integrated circuits, which is applied in the field of manufacturing the anode film of parts of integrated circuit manufacturing equipment, can solve problems affecting the performance of parts, etc., and achieve the effects of prolonging service life, reducing costs, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Choose an aluminum alloy plate with a length of 20cm, a width of 10cm, and a thickness of 1cm as the substrate of the anode film;

[0031] In the cleaning step, the substrate is put into an organic solution for surface cleaning, and the organic solution is an isopropanol solution with a concentration of 99%;

[0032] In the alkaline washing step, the substrate is put into a sodium hydroxide solution with a ratio of sodium hydroxide and water of 1:10 for alkaline washing;

[0033] Grinding step: grinding the surface of the substrate to remove uneven surface and make the surface of the substrate smooth;

[0034] In the roughening treatment step, a sandblasting machine is used to spray the surface of the substrate with glass sand as the abrasive, the sandblasting pressure is controlled at 1kg / cm2, and the surface of the substrate is finely roughened to make the surface roughness of the substrate 0.9μm;

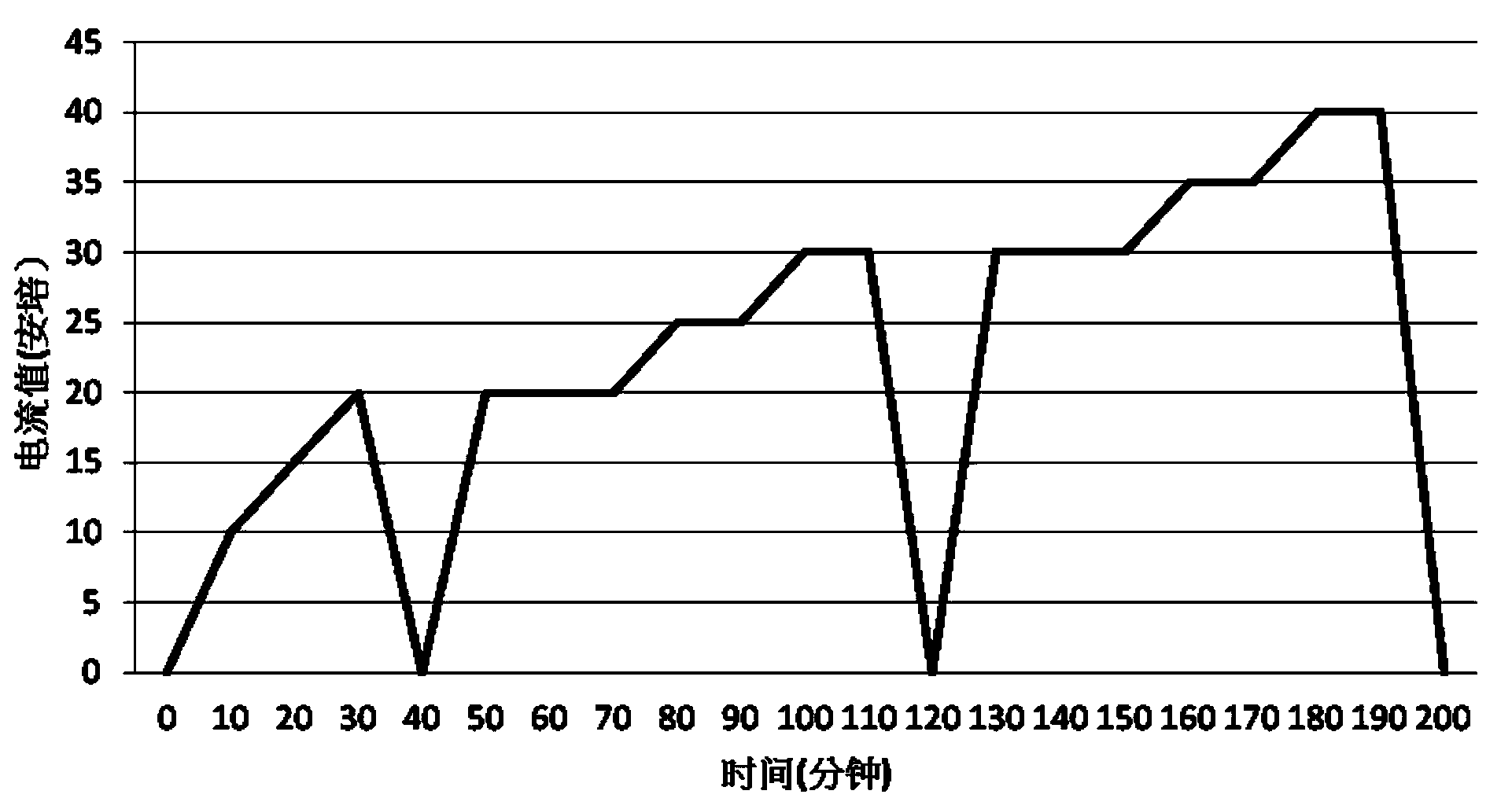

[0035] In the film formation step, the substrate is placed in an anode tank co...

Embodiment 2

[0038] Choose an aluminum alloy plate with a length of 15cm, a width of 15cm, and a thickness of 1cm as the substrate of the anode film;

[0039] In the cleaning step, the substrate is put into an organic solution for surface cleaning, and the organic solution is an isopropanol solution with a concentration of 99%;

[0040] In the alkaline washing step, the substrate is put into a sodium hydroxide solution with a ratio of sodium hydroxide and water of 1:10 for alkaline washing;

[0041] Grinding step: grinding the surface of the substrate to remove uneven surface and make the surface of the substrate smooth;

[0042] In the roughening treatment step, a sandblasting machine is used to spray the surface of the substrate with glass sand as the abrasive. The pressure of the sandblasting machine is controlled at 1kg / cm2, and the surface of the substrate is finely roughened to make the surface of the substrate rough. The degree is 1μm;

[0043] In the film formation step, the substrate is pl...

Embodiment 3

[0046] Choose an aluminum alloy plate with a length of 25cm, a width of 10cm, and a thickness of 1cm as the substrate of the anode film;

[0047] In the cleaning step, the substrate is put into an organic solution for surface cleaning, and the organic solution is a 99% isopropanol solution;

[0048] In the alkaline washing step, the substrate is put into a sodium hydroxide solution with a ratio of sodium hydroxide and water of 1:10 for alkaline washing;

[0049] Grinding step: grinding the surface of the substrate to remove uneven surface and make the surface of the substrate smooth;

[0050] In the roughening treatment step, a sandblasting machine is used to spray the surface of the substrate with glass sand as the abrasive, and the sandblasting pressure is controlled at 1kg / cm2. The surface of the substrate is subjected to fine roughening treatment to make the surface roughness of the substrate 0.8μm;

[0051] In the film formation step, the substrate is placed in an anode tank conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com