Full-automatic commercial pure titanium smelting method adopting electron beam cold hearth furnace

A technology of electron beam cold hearth furnace and industrial pure titanium, which is applied in the field of smelting TA1 and electron beam cold heart furnace for fully automatic smelting of industrial pure titanium. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

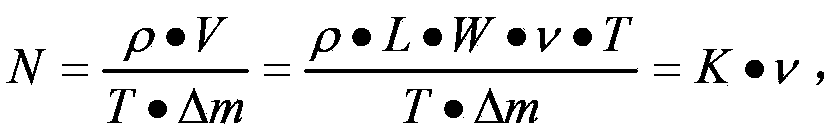

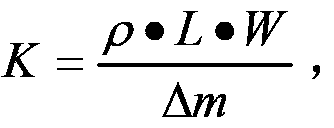

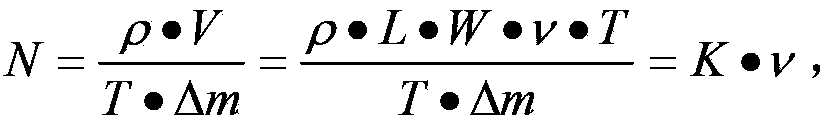

[0031] Dry titanium sponge with a purity of 99.7% and a particle size of 0.83-25.4mm at a temperature of 60°C and a vacuum of 0.6Pa. The cylinder is installed in the feeding system of the EB furnace. Set its rotation speed as Nr / min, and when the vacuum degree is 0.4-0.8Pa; when the vacuum degree of the main smelting furnace body is 0.05-0.8Pa, open the feeding system to feed the material rotated by the Archimedes spiral cylinder into the main smelting furnace On the smelting cooling bed in the chamber, turn on the electron gun to melt the sponge titanium into titanium liquid. The titanium liquid flows through the primary refining cooling bed, and after the main refining cooling bed, it flows into the rectangular (1380*200mm) crystal pulling crucible, and the ingot is pulled by the ingot pulling system. The crystal pulling crucible is taken out, and the flat titanium billet ingot can be obtained after cooling with the furnace. The specific implementation process is shown in T...

Embodiment 2

[0035] Dry titanium sponge with a purity of 99.7% and a particle size of 0.83-25.4mm at a temperature of 60°C and a vacuum of 0.6Pa. The cylinder is installed in the feeding system of the EB furnace. Set its rotation speed as Nr / min, and when the vacuum degree is 0.4-0.8Pa; when the vacuum degree of the main smelting furnace body is 0.05-0.8Pa, open the feeding system to feed the material rotated by the Archimedes spiral cylinder into the main smelting furnace On the smelting cooling bed in the chamber, turn on the electron gun to melt the sponge titanium into titanium liquid. The titanium liquid flows through the primary refining cooling bed, and after the main refining cooling bed, it flows into the rectangular (1250*200mm) crystal pulling crucible, and the ingot is pulled by the ingot pulling system. The crystal pulling crucible is taken out, and the flat titanium billet ingot can be obtained after cooling with the furnace. The specific implementation process is shown in T...

Embodiment 3

[0039]Dry titanium sponge with a purity of 99.7% and a particle size of 0.83-25.4mm at a temperature of 60°C and a vacuum of 0.6Pa. The cylinder is installed in the feeding system of the EB furnace. Set its rotation speed as Nr / min, and when the vacuum degree is 0.4-0.8Pa; when the vacuum degree of the main smelting furnace body is 0.05-0.8Pa, open the feeding system to feed the material rotated by the Archimedes spiral cylinder into the main smelting furnace On the smelting cooling bed in the chamber, turn on the electron gun to melt the sponge titanium into titanium liquid. The titanium liquid flows through the primary refining cooling bed, and after the main refining cooling bed, it flows into the rectangular (1050*200mm) crystal pulling crucible, and the ingot is pulled by the ingot pulling system. The crystal pulling crucible is taken out, and the flat titanium billet ingot can be obtained after cooling with the furnace. The specific implementation process is shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com