Rubber composite containing graphene oxide

A composite material, hydrogenated nitrile rubber technology, applied in the field of graphene oxide-containing rubber composite materials, can solve the problems of insufficient peeling degree, poor adhesion of expanded graphite dispersion interface, limited improvement of composite material modulus and hardness, etc., to achieve Improve the hardness and modulus, improve the service life, and the effect of good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

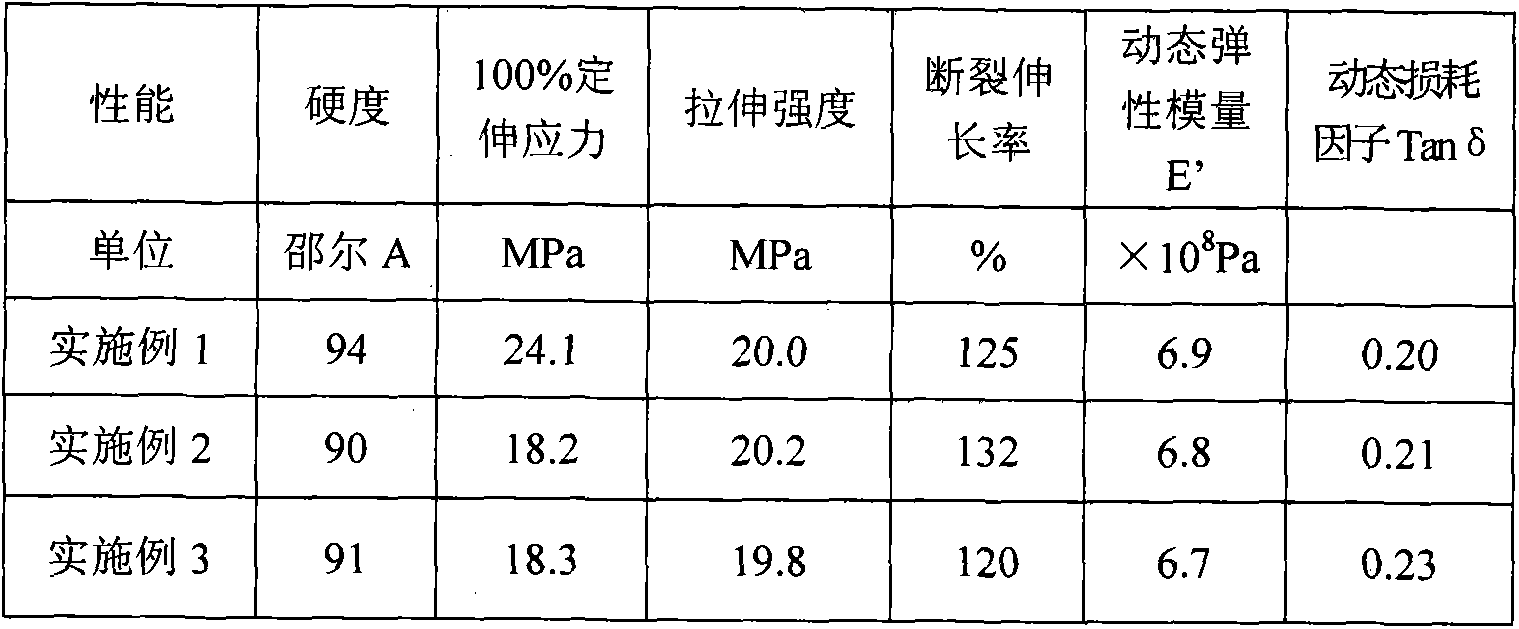

Embodiment 1

[0028] Embodiment 1: a kind of graphene oxide-containing rubber composite material, the mass fraction of each component is: 100 parts of chlorosulfonated polyethylene, 10 parts of ethylene-vinyl acetate rubber (EVM), 20 parts of hydrogenated nitrile rubber ( HNBR), 3 parts of graphene oxide, 60 parts of hard carbon black N33060, 4 parts of dioctyl sebacate (DOS), 2 parts of stearic acid, 5 parts of zinc oxide, 5 parts of insoluble sulfur, antioxidant N, N- 3 parts of nickel dibutyl dithiocarbamate, 2 parts of vulcanizing agent PbO, 3 parts of vulcanization accelerator bispentamethylenethiuram hexasulfide.

[0029] Composite material preparation process: disperse graphene oxide powder in deionized water with a mass concentration of 0.4 mg / mL, and use an ultrasonic wave with a power of 750 W for 45 minutes to obtain a water suspension system of graphene oxide. Add 100 parts of chlorosulfonated polyethylene to the suspension system for ultrasonic treatment for 15min, add 2wt% CaC...

Embodiment 2

[0030] Embodiment 2: a kind of rubber composite material containing graphene oxide, the mass fraction of each component is: 100 parts of chlorosulfonated polyethylene, 15 parts of ethylene-vinyl acetate rubber (EVM), 25 parts of hydrogenated nitrile rubber ( HNBR), 0.5 parts of graphene oxide, 60 parts of hard carbon black N330, 4 parts of dioctyl sebacate (DOS), 3 parts of stearic acid, 6 parts of zinc oxide, 2 parts of insoluble sulfur, antioxidant N, N- 3 parts of nickel dibutyldithiocarbamate, 4 parts of vulcanizing agent PbO, 3 parts of vulcanization accelerator bispentamethylenethiuram hexasulfide.

[0031] Composite material preparation process: disperse graphene oxide powder in deionized water with a mass concentration of 0.4 mg / mL, and use an ultrasonic wave with a power of 750 W for 45 minutes to obtain a water suspension system of graphene oxide. Add 100 parts of chlorosulfonated polyethylene to the suspension system for ultrasonic treatment for 15min, add 2wt% CaCl...

Embodiment 3

[0032] Embodiment 3: a kind of graphene oxide-containing rubber composite material, the mass fraction of each component is: 100 parts of chlorosulfonated polyethylene, 12 parts of ethylene-vinyl acetate rubber (EVM), 22 parts of hydrogenated nitrile rubber ( HNBR), 5 parts of graphene oxide, 50 parts of hard carbon black N330, 5 parts of dioctyl sebacate (DOS), 3 parts of stearic acid, 6 parts of zinc oxide, 6 parts of insoluble sulfur, antioxidant N, N- 3 parts of nickel dibutyldithiocarbamate, 4 parts of vulcanizing agent PbO, 3 parts of vulcanization accelerator bispentamethylenethiuram hexasulfide.

[0033] Composite material preparation process: disperse graphene oxide powder in deionized water with a mass concentration of 0.4 mg / mL, and use an ultrasonic wave with a power of 750 W for 45 minutes to obtain a water suspension system of graphene oxide. Add 100 parts of chlorosulfonated polyethylene to the suspension system for ultrasonic treatment for 15min, add 2wt% CaCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com