Modularization installing construction method for slab continuous casting machine bale rotary table

A technology of ladle rotary table and slab continuous casting machine, which is applied to casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of construction period and construction cost, increase construction safety hazards, and increase risk factor, etc. Achieve the effects of shortening the construction period, improving construction quality, and reducing high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below with reference to accompanying drawing and example:

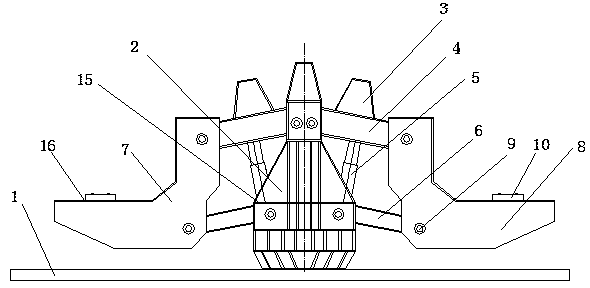

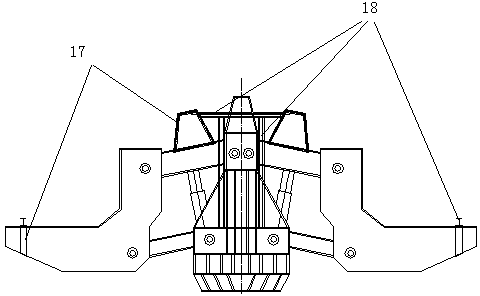

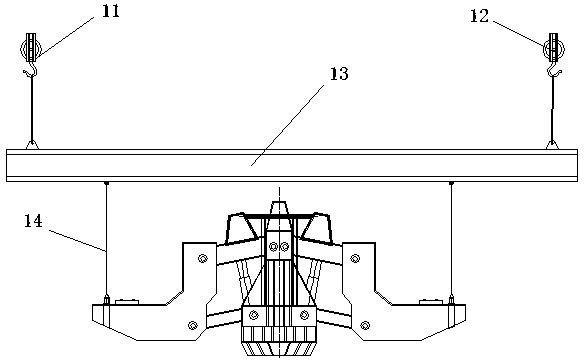

[0050] attached Figures 1 to 3 It can be seen that a modular installation and construction method of a ladle turret for a slab continuous casting machine includes the following steps:

[0051] A. Large bag rotary table is assembled in pairs;

[0052] B. Reinforce the pin shaft and pin position of the bale turntable; ensure that the 9 parts of the pin shaft and the hydraulic cylinder 5 are in a fixed position, and the entire turntable forms a rigid whole;

[0053] C. The hoisting of the bale turntable is in place.

[0054] The assembling steps of the bale turntable group are as follows:

[0055] ⑴ The assembly platform 1 is laid on a flat site at the construction site;

[0056] ⑵ Install the turntable 2 and level the turntable 2;

[0057] (3) Install the hydraulic cylinder 5;

[0058] (4) Install the upper connecting rod 4 and the hydraulic cylinder bracket 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com