Polishing material and polishing composition

A technology of abrasive materials and compositions, which is applied in the direction of polishing compositions containing abrasives, grinding devices, grinding machine tools, etc., and can solve problems such as insufficient satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] One embodiment of the present invention will be described below.

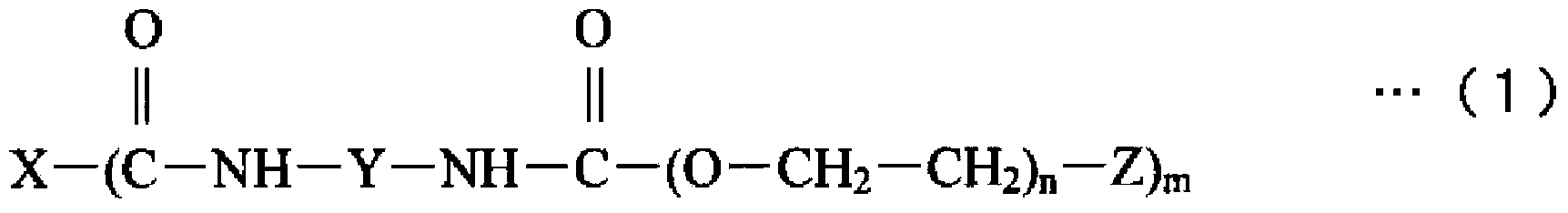

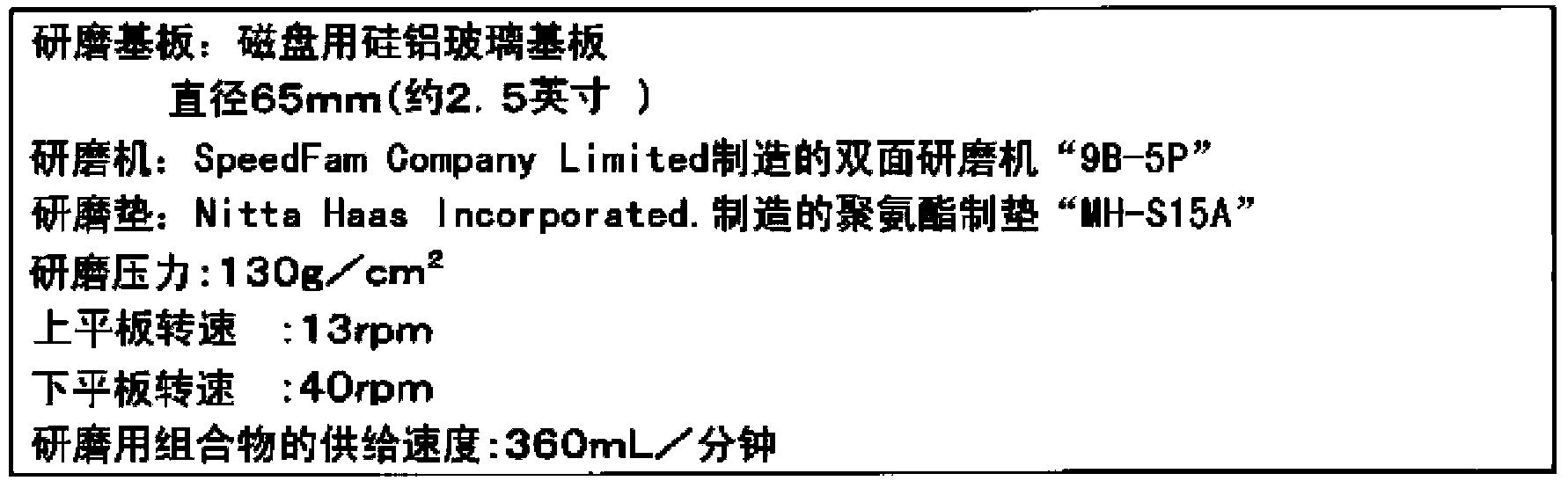

[0020] The polishing composition of this embodiment contains an abrasive and water. The abrasive material contains zirconia particles. The polishing composition is suitable for use in polishing hard and brittle materials such as sapphire, silicon nitride, silicon carbide, silicon oxide, glass, gallium nitride, gallium arsenide, indium arsenide, and indium phosphide.

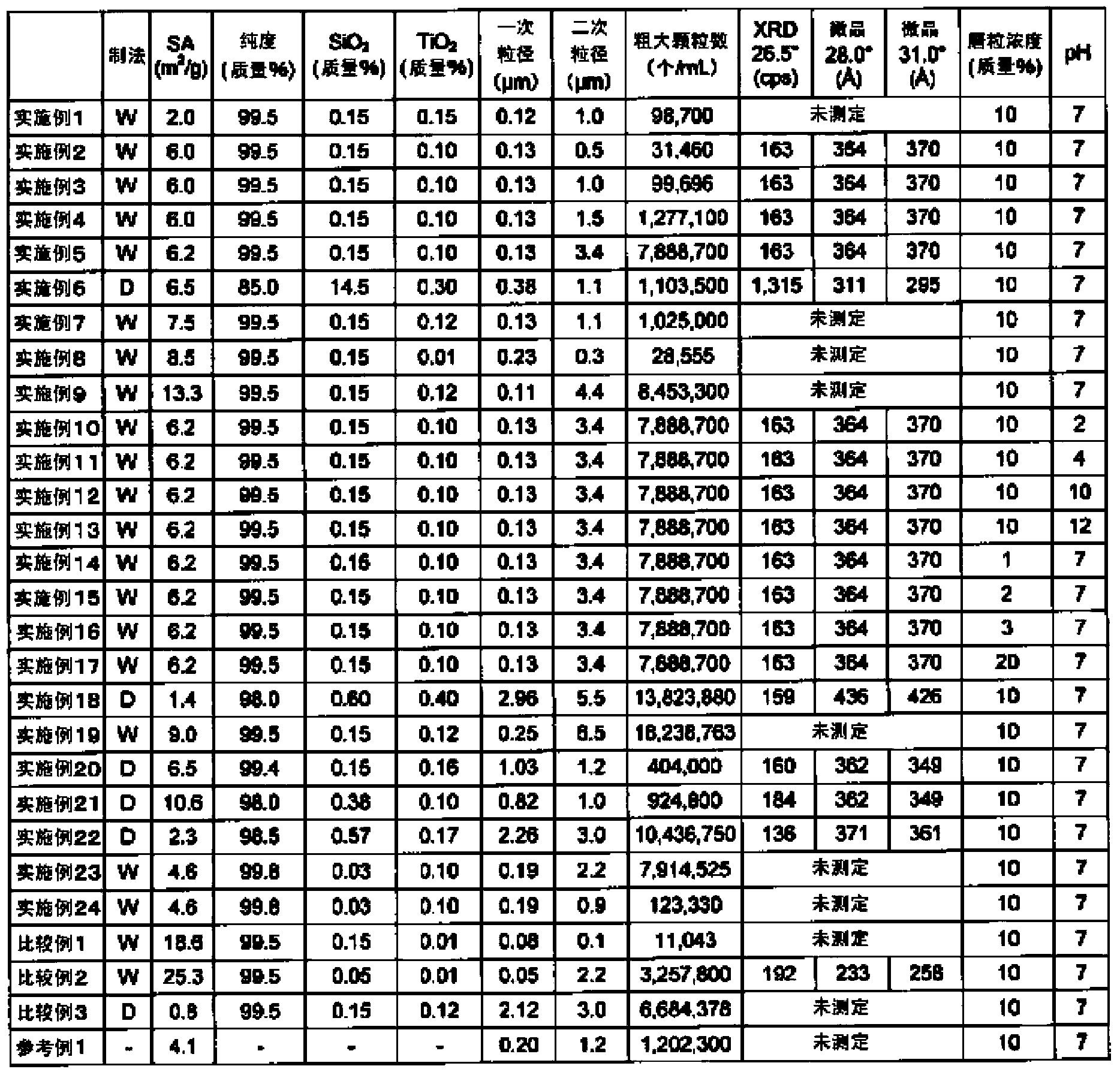

[0021] The zirconia particles contained in the abrasive may be particles of crystalline zirconia such as cubic system, tetragonal system, and monoclinic system, or particles of amorphous zirconia. As the abrasive, tetragonal or monoclinic zirconia is preferable. Zirconia particles may also contain calcium, magnesium, hafnium, yttrium, silicon, and the like. Among them, the purity of the zirconia particles is preferably as high as possible, specifically, preferably 99% by mass or more, more preferably 99.5% by mass or more, even more pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com